Mildew-proof drying sheet and production technology thereof

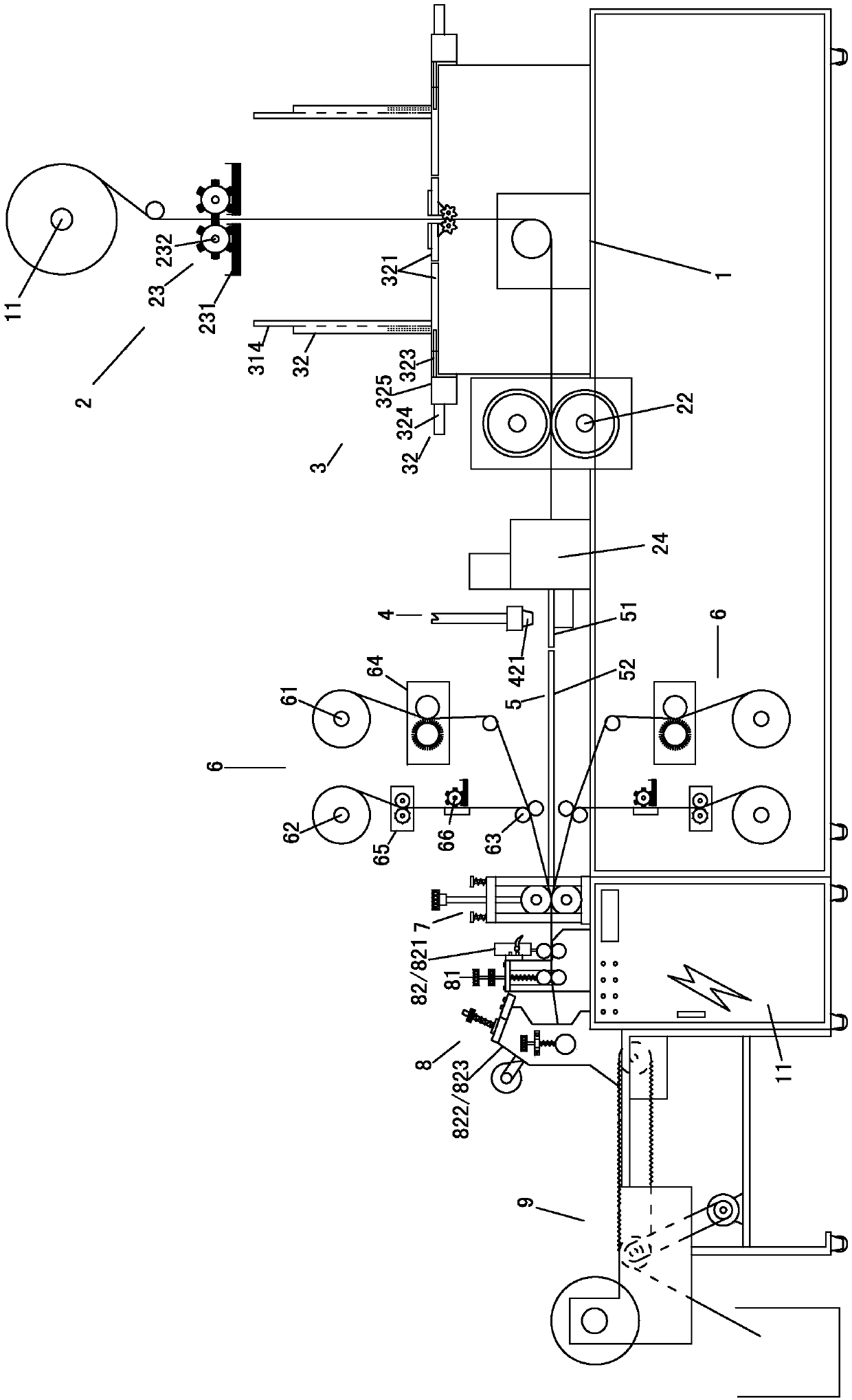

A production process and technology of drying sheets, applied in the field of anti-mold drying sheets and its production technology, can solve the problems of mechanical packaging that cannot be fully automated, difficult manufacturing costs of anti-mold drying sheets, high mechanical input costs, etc., to achieve Low cost, reduced production cost, and convenient setup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

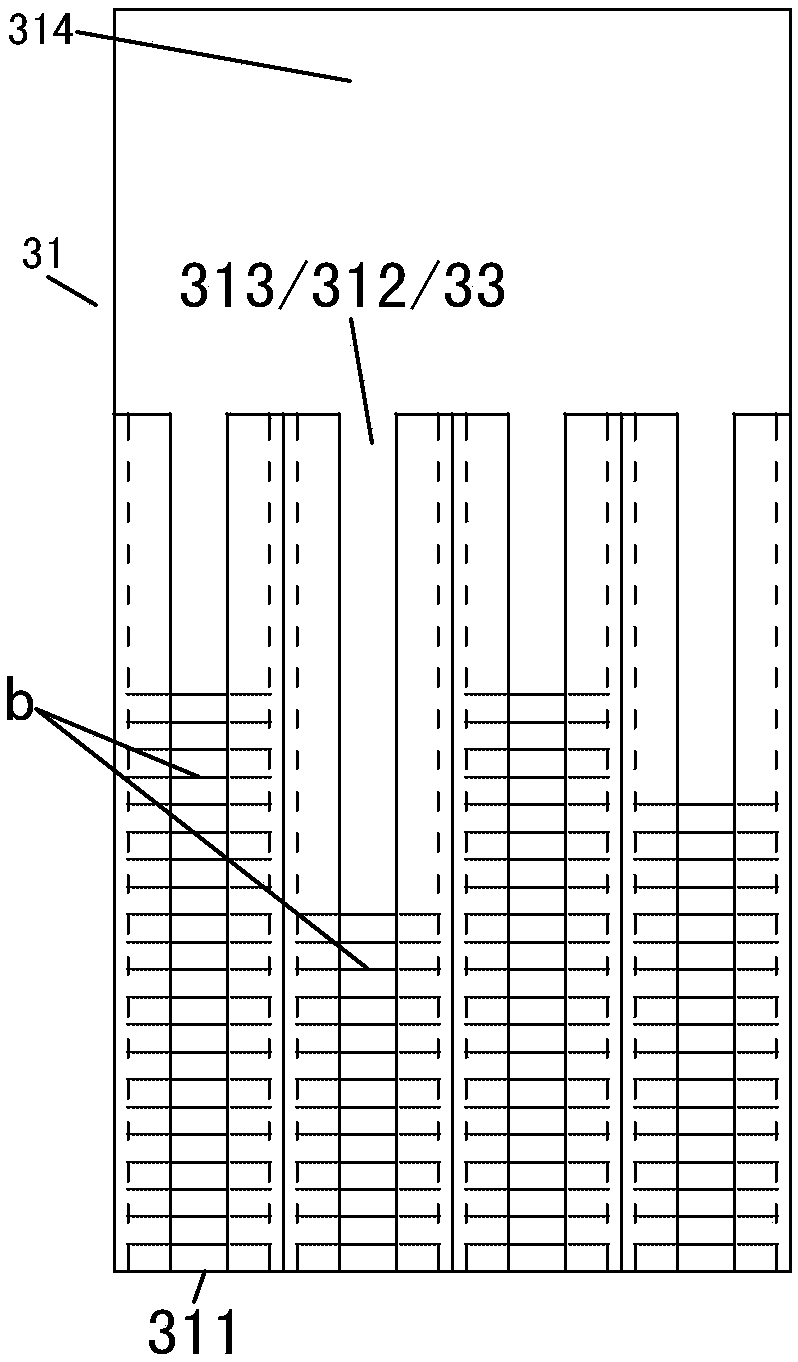

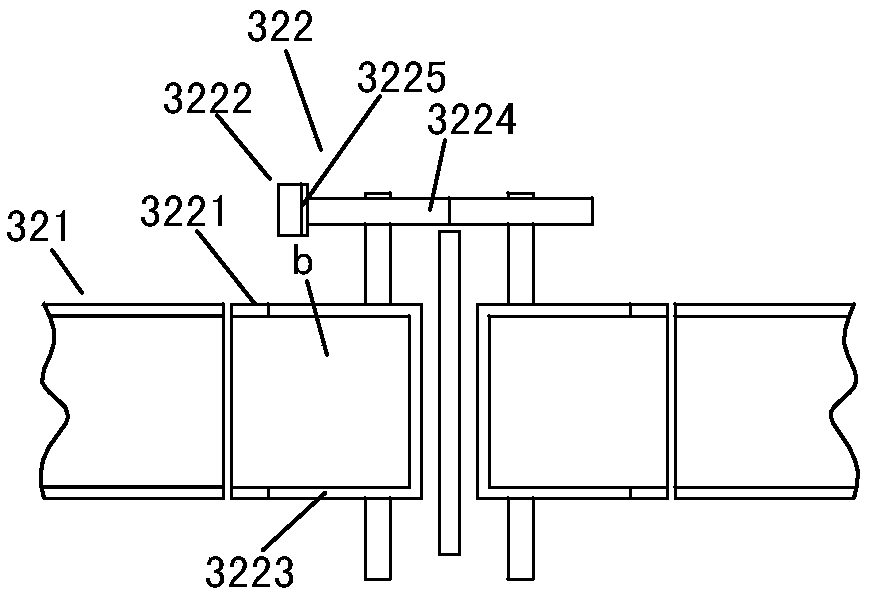

Method used

Image

Examples

Embodiment 1

[0085] Embodiment one, such as Figure 14As shown, a mildew-resistant drying sheet includes a drying sheet substrate b sprayed with a chemical solution and an outer packaging layer c1 that covers the drying sheet substrate b by edge pressing, and the outer packaging layer c1 includes a corresponding The first packaging layer and the second packaging layer that wrap the drying sheet base material b inside are set by edge pressing, that is, the first packaging layer and the second packaging layer that are distributed on both sides of the drying sheet base material b. The difference between some anti-mildew drying sheets is that the outer packaging layer c is provided with an opening and using structure of the anti-mildew drying sheet, and the opening and using structure is a structure formed during the packaging production process, that is, it can be realized mechanically and automatically. The formed structure does not require manual production and packaging work, and this stru...

Embodiment 2

[0098] Embodiment two, such as Figure 15 As shown, the difference from Example 1 is that a spacer a1 is provided between the first packaging layer and the second packaging layer, and the drying sheet substrate b is respectively provided on the middle areas of both sides of the spacer a1, The edges of the spacer a1 are all pressed together with the edges of the first packaging layer and the second packaging layer, and the opening and use structures are respectively provided on the first packaging layer and the second packaging layer, as shown in the figure, The anti-mildew drying sheet of this structure is a one-piece structure with two separate pieces after it is produced and packaged. Use one, open the other after you feel that the smell is volatile or not, or use it at the same time, that is, open the two at the same time, the volatilization of this moldy liquid may be more concentrated, which is suitable for those who need better anti-mold effect or the use of larger spac...

Embodiment 3

[0114] Embodiment three, the difference with the above-mentioned embodiment one and embodiment two is, as Figure 16 As shown, on the basis of the above two structures, a hanging through hole c4 is provided on the side of the bonding sheet c2 and the outer packaging layer c1; Fix the shape of the molding strip c3, the two ends of the molding strip c3 are respectively facing the two sides of the adhesive sheet c2 and the outer packaging layer c1, and the anti-mildew drying sheet of this structure can pass through the hanging through hole C4 is suspended, and there is no need to paste and fix it through the adhesive sheet c2, and the plastic strip c3 can shape the adhesive sheet c2 after opening and tearing the adhesive sheet c2, so that it will not be attached to the outer packaging layer c1 and cover the volatilization hole c11 Affects volatilization, when the anti-mildew drying sheet of this structure is produced and packaged, the formation of the hanging through hole c4 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com