A combined garbage disposal equipment

A garbage disposal equipment and combined technology, which is applied in the direction of grain processing, material molding presses, manufacturing tools, etc., can solve the problems of fast and convenient, unable to be pressed into solid, unable to compress the volume of garbage to the minimum, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

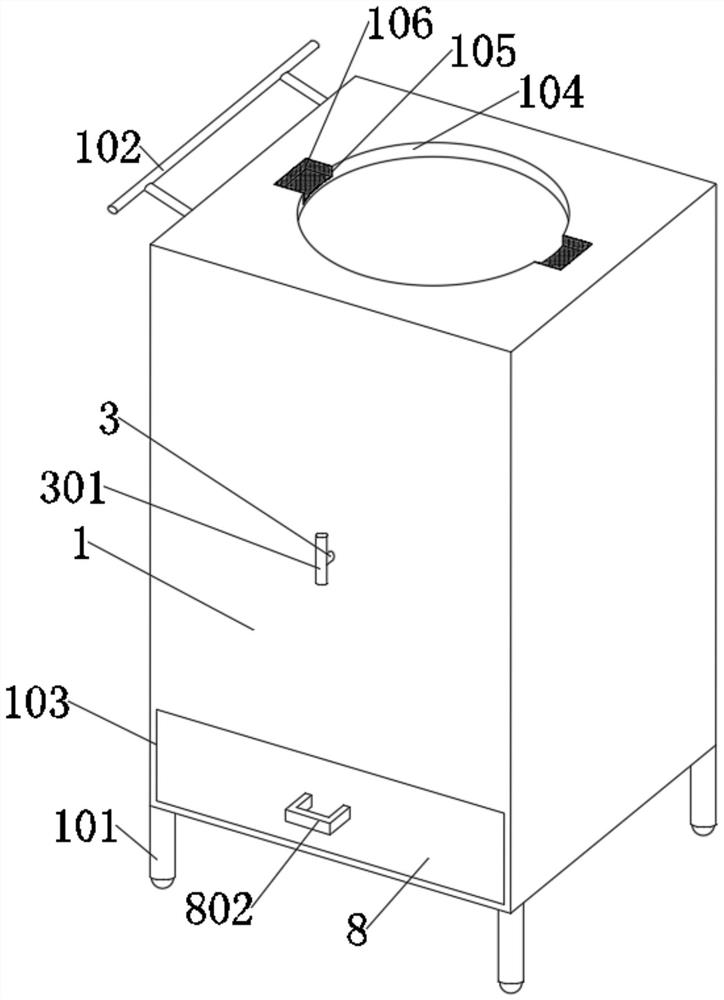

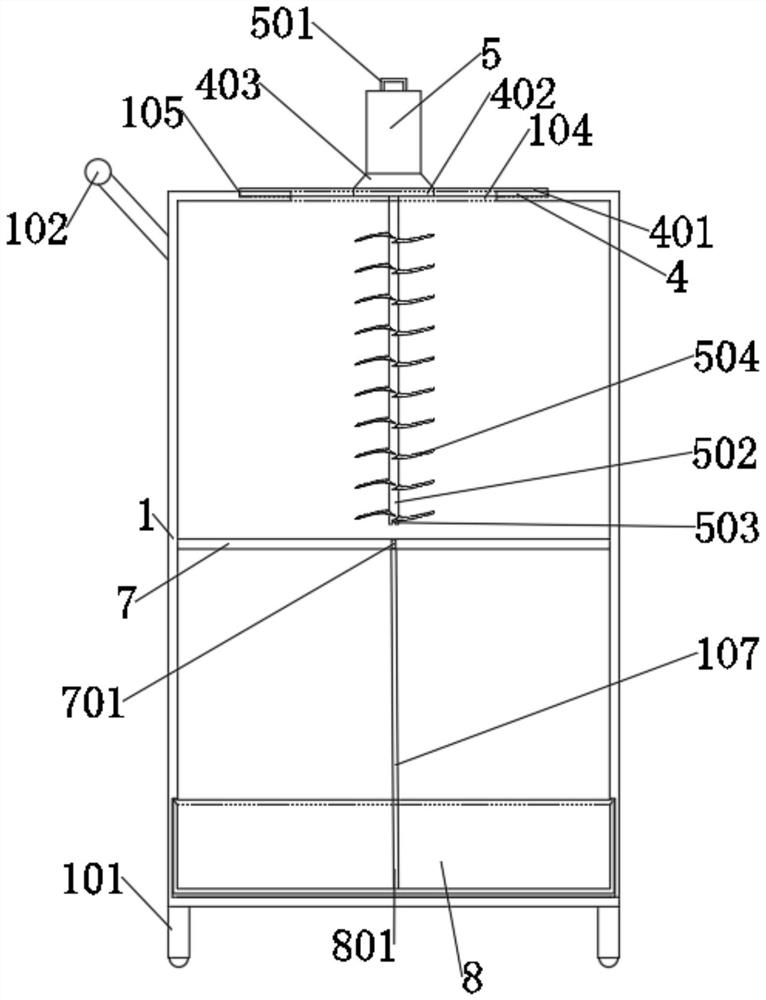

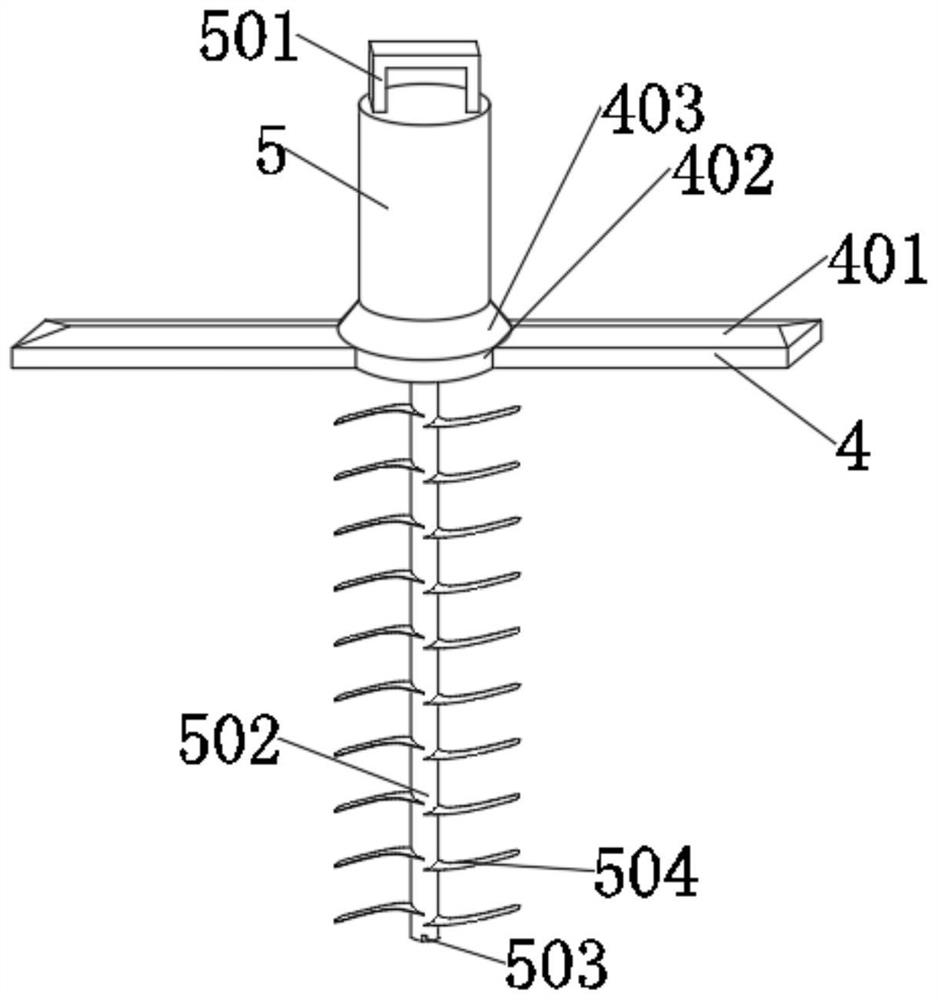

[0032] as attached figure 1 to attach Figure 8 Shown:

[0033] The present invention provides a combined garbage disposal equipment, including: a main body 1, a universal wheel 101, a push rod 102, an insertion port 103, a feeding port 104, an installation port 105, a rubber pad 106, a moving groove 107, and a rotating port 2 , the inner chamber 201, the stopper 202, the rotating shaft 3, the manual member 301, the rotating member 302, the embedded groove 303, the support rod 4, the guide member 401, the fixing member 402, the diverter member 403, the positive and negative speed regulating motor 5, and the Pull piece 501, installation shaft 502, bayonet socket 503, crushing cutter head 504, extension rod 6, insertion head 601, retraction rod 602, clip 603, receiving plate 7, insertion block 701, circular groove 702, collection bin 8 , the lower pressure groove 801 and the handle 802; the main body 1 is a rectangular internal hollow structure, and the bottom corner of the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com