Linear sliding assembly

A linear sliding and assembly technology, used in auxiliary devices, supporting machines, auxiliary welding equipment, etc., can solve the problems of increasing sliding friction, short service life, and easy damage, avoiding accumulation, improving sliding stability, extending The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

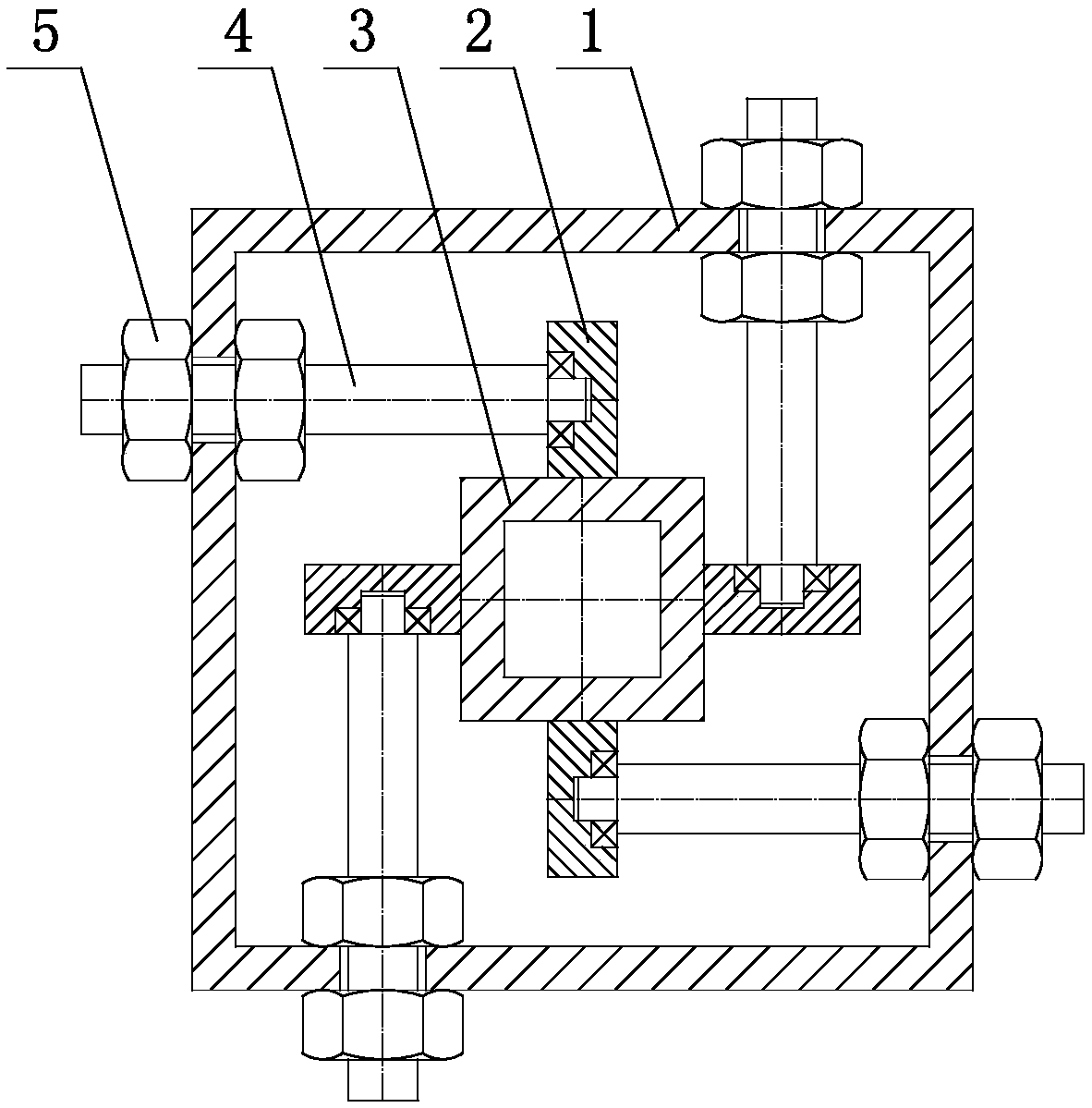

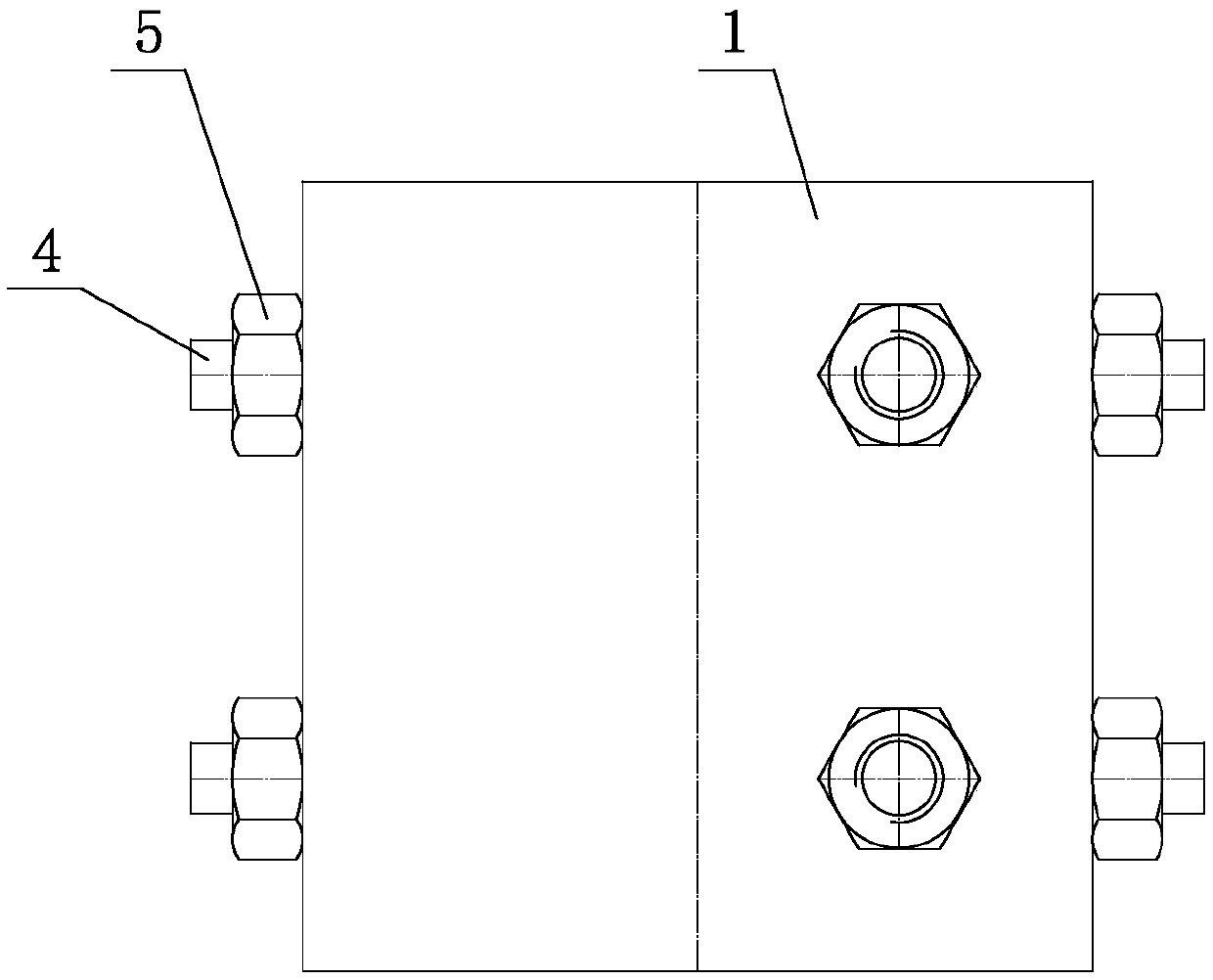

[0019] like figure 1 , figure 2 As shown, the linear sliding assembly includes an outer square tube 1 arranged horizontally, an inner square tube 3 is installed horizontally inside the outer square tube 1, and an inner square tube 3 is installed on the upper, lower, left and right sides of the inner square tube 3. Positioning shafts 4, each positioning shaft 4 is mounted on the outer tube, each positioning shaft 4 is provided with a rotating roller 2, and each rotating roller 2 is distributed on the upper surface, bottom, left side of the inner square tube 3 On the side and the right side, each positioning shaft 4 is provided with threads, and each positioning shaft 4 is installed on the outer tube 1 through a nut 5 .

[0020] In this embodiment, each rotating roller 2 is mounted on the positioning shaft 4 through a bearing. The technical design of this section improves the flexibility of the rotary roller 2 and prevents waste residues from entering the bearings in the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com