Low energy consumption and self-feeding transformer processing device for new energy automobile

A new energy vehicle and processing device technology, applied to presses, manufacturing tools, etc., can solve problems such as increasing energy consumption, affecting processing efficiency, and increasing production costs, so as to improve work efficiency, reduce energy consumption, and avoid local deformation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below, the technical solution of the present invention will be described in detail through specific examples.

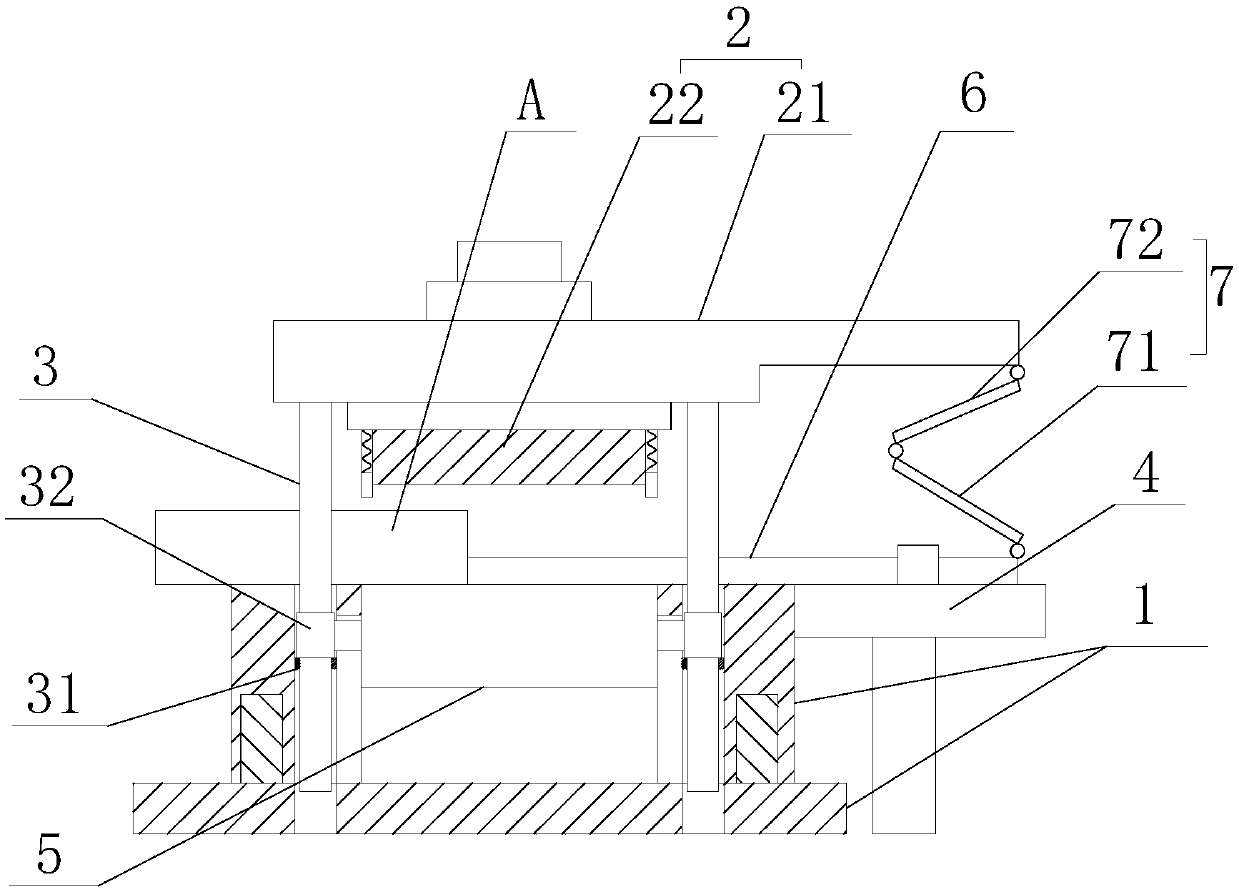

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a low-energy self-cutting transformer processing device for new energy vehicles proposed by the present invention.

[0017] refer to figure 1 , a low-energy self-cutting transformer processing device for new energy vehicles proposed in the embodiment of the present invention, comprising: a lower die 1, an upper die 2 located above the lower die 1, and a device for driving the upper die 2 to move up and down Drive mechanism, and pull rod 3 and guiding platform 4, wherein:

[0018] The lower die 1 is provided with a cavity and guide holes located outside the cavity. A bottom plate 5 that can slide up and down is arranged in the cavity, and the side wall of the bottom plate 5 is provided with a connecting portion, and the connecting portion is located in the chute. The depth o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com