Mortar painting vehicle

A mortar and car body technology, applied in the direction of construction, building construction, etc., can solve the problems of slow smearing speed, high labor intensity, uneven smearing, etc., and achieve the effects of reducing cavities and air bubbles, simplifying the structure, and avoiding delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

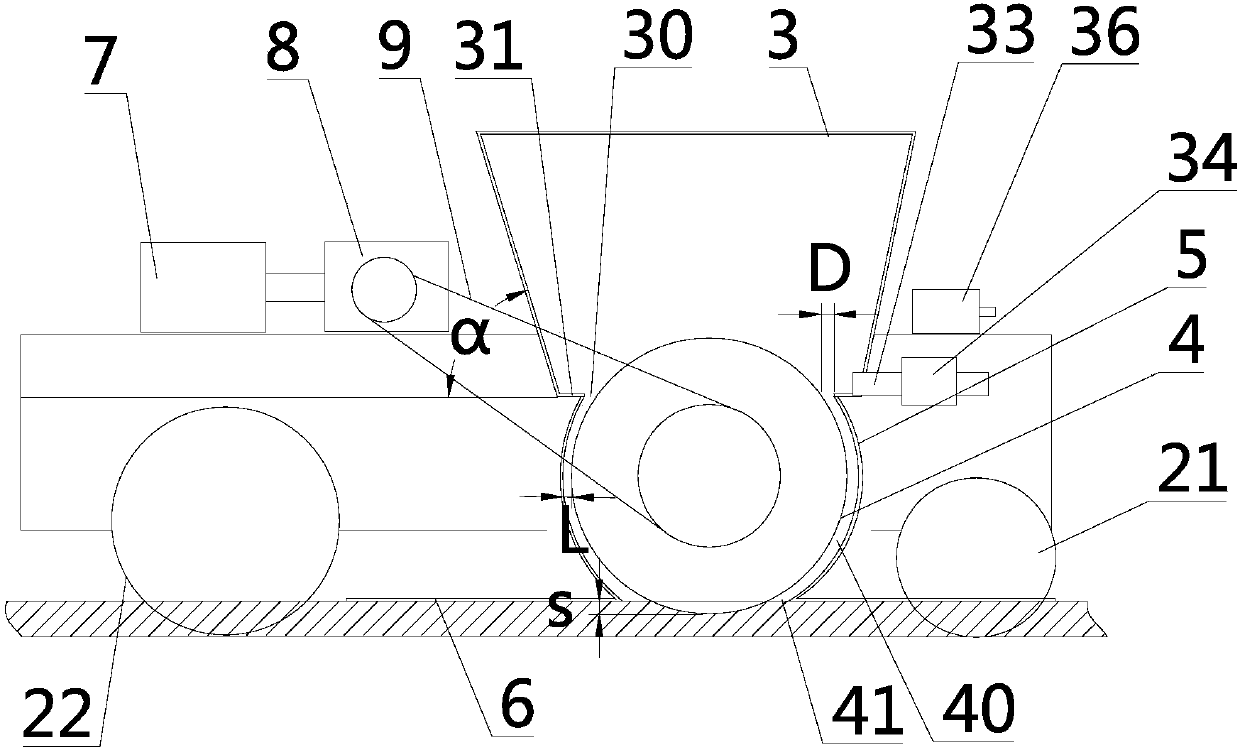

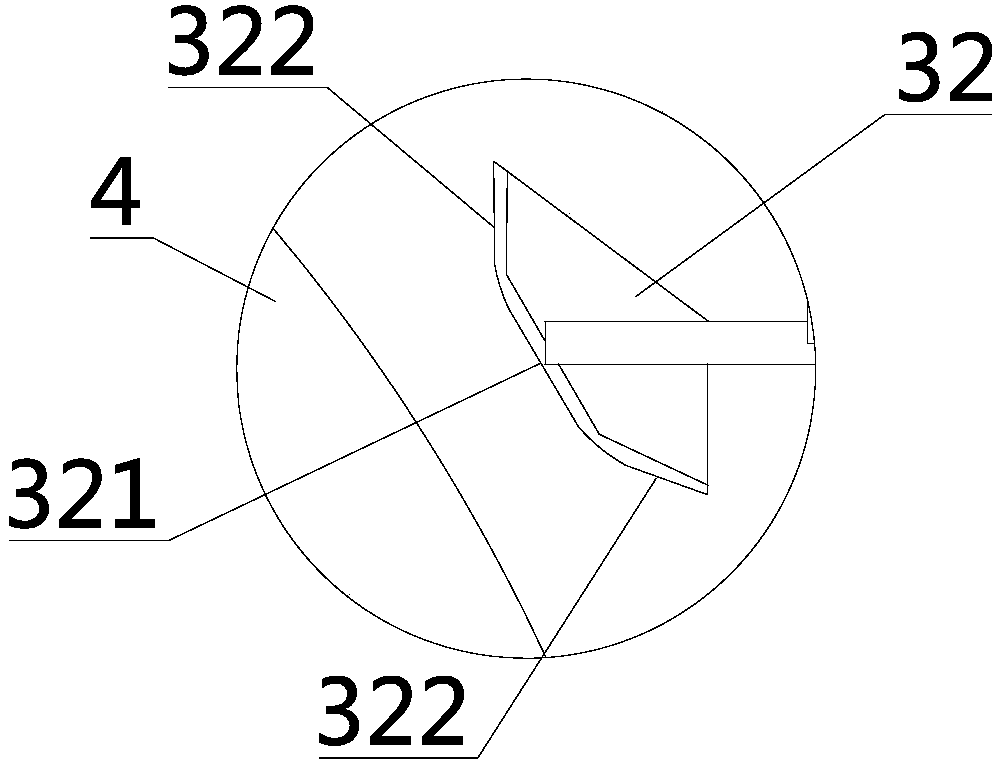

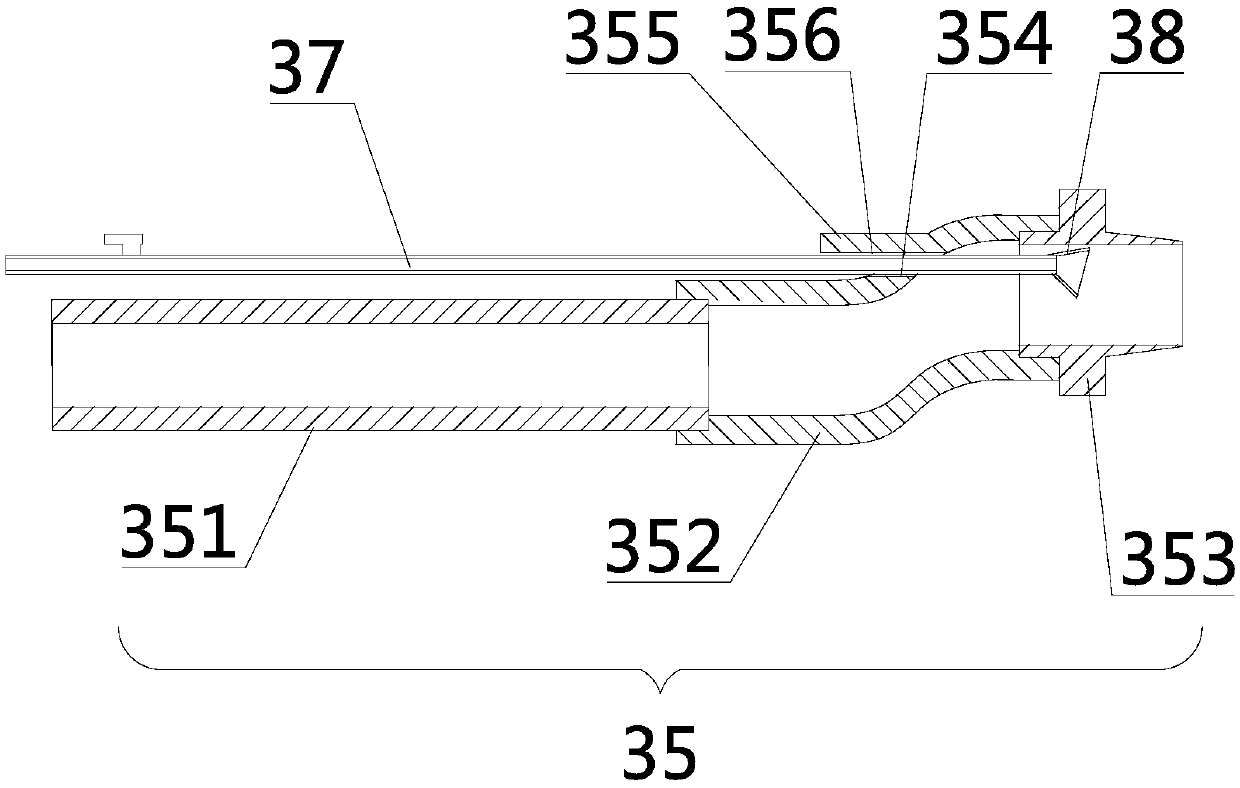

[0013] The invention provides a mortar application vehicle, such as Figure 1 to Figure 3 As shown, it includes a car body 1, a front wheel 21, a rear wheel 22 and a mortar box 3 arranged on the car body 1. A mortar smearing structure is arranged under the car body 1, and the mortar smearing structure is located between the front wheel 21 and the rear wheel 22. The mortar smearing structure includes a mortar drum 4, a mortar drum shell 5 and a plastering plate 6 for smoothing the mortar. The mortar drum shell 5 is provided with an extrusion chamber 40 communicating with the inner cavity of the mortar box 3, and the mortar drum 4 is arranged laterally. It is connected to the wall of the extrusion chamber 40 by rotation, the bottom of the extrusion chamber 40 is provided with a slurry outlet 41, the length S of the bottom of the mortar drum 4 protruding from the slurry outlet 41 is 2 mm to 7 mm, and the trowel 6 is close to the The ground to be laid extends outwards from the edg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com