Environment-friendly coating storage tank

An environmentally friendly coating and storage tank technology, which is applied to tank cars, transport passenger cars, railway car body parts, etc., can solve the problems of environmental protection coating failure, environmental protection coating residue, affecting use, etc., and achieve the effect of improving fire resistance and prolonging storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

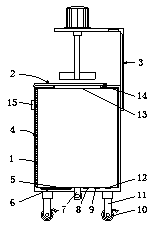

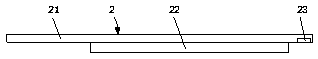

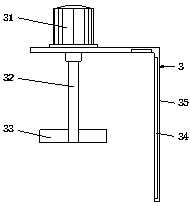

[0021] See Figure 1-4 , An environmentally friendly paint storage tank, comprising a tank body 1, the tank body 1 is made of metal, and the bottom of the inner cavity of the tank body 1 is embedded with a refrigeration plate 6, a pressure sensor 8, a consistency sensor 9 and a temperature sensor from left to right. 12. The model of the temperature sensor 12 is HD-PT100. The temperature sensor 12 can detect the temperature of the environmentally friendly paint, and display the detection result through the display 15. At the same time, people can set the temperature detected by the temperature sensor 12 through an external controller Temperature range, when the temperature of the environmentally friendly paint is higher than its highest preset value, the temperature sensor 12 automatically turns on the power supply of the refrigeration board 6, and when the temperature of the environmentally friendly paint is lower than its lowest preset value, the temperature sensor 12 automatic...

Embodiment 2

[0023] See Figure 1-4 , An environmentally friendly paint storage tank, comprising a tank body 1, the tank body 1 is made of metal, and the bottom of the inner cavity of the tank body 1 is embedded with a refrigerating plate 6, a pressure sensor 8, a consistency sensor 9 and a temperature sensor from left to right. 12. The model of the temperature sensor 12 is HD-PT100. The temperature sensor 12 can detect the temperature of the environmentally friendly paint, and display the detection result through the display 15. At the same time, people can set the temperature detected by the temperature sensor 12 through an external controller Temperature range. When the temperature of the environmentally friendly paint is higher than its highest preset value, the temperature sensor 12 automatically turns on the power supply of the refrigeration board 6, and when the temperature of the environmentally friendly paint is lower than its lowest preset value, the temperature sensor 12 automatic...

Embodiment 3

[0025] See Figure 1-4 , An environmentally friendly paint storage tank, comprising a tank body 1, the tank body 1 is made of metal, and the bottom of the inner cavity of the tank body 1 is embedded with a refrigerating plate 6, a pressure sensor 8, a consistency sensor 9 and a temperature sensor from left to right. 12. The model of the temperature sensor 12 is HD-PT100. The temperature sensor 12 can detect the temperature of the environmentally friendly paint, and display the detection result through the display 15. At the same time, people can set the temperature detected by the temperature sensor 12 through an external controller Temperature range. When the temperature of the environmentally friendly paint is higher than its highest preset value, the temperature sensor 12 automatically turns on the power supply of the refrigeration board 6, and when the temperature of the environmentally friendly paint is lower than its lowest preset value, the temperature sensor 12 automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com