Stone-like coating and processing equipment and processing method thereof

A stone-like coating and processing method technology, applied to chemical instruments and methods, coatings, transportation and packaging, etc., can solve the problems of poor simulation of coatings, achieve good simulation, poor simulation, and improve granulation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

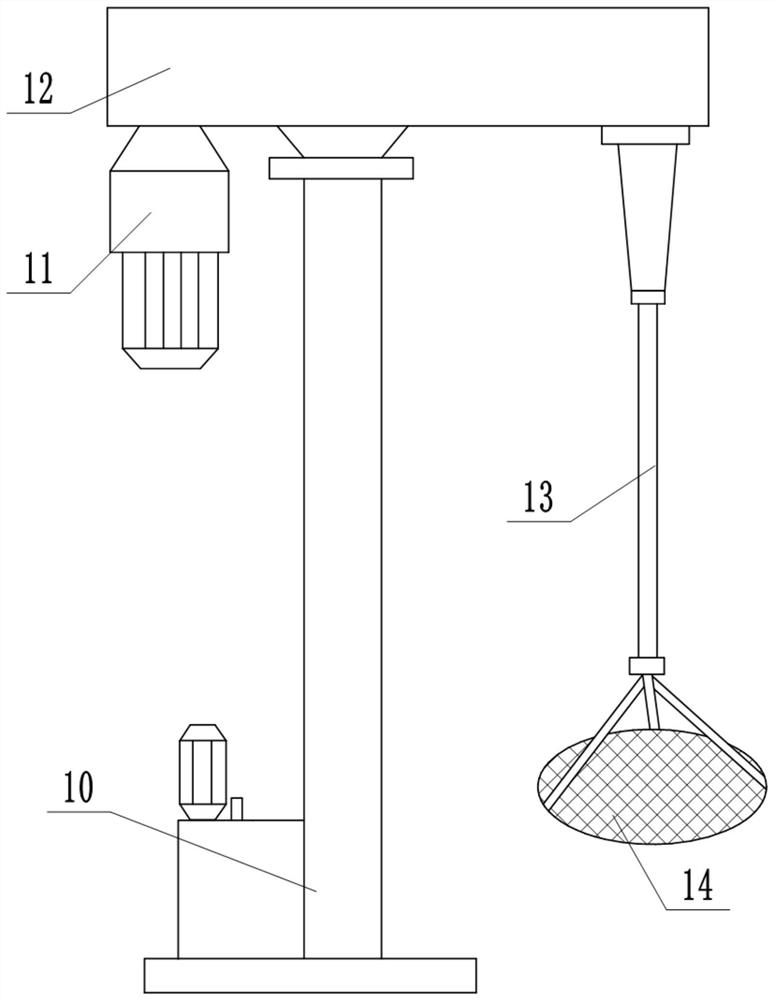

Embodiment 1

[0039] The imitation stone paint includes a dispersed phase, a protective agent and a continuous phase, and the mass-number ratio of the dispersed phase, protective agent and continuous phase is 5:3:2.

[0040] The protective agent includes 920 parts of deionized water, 1.2 parts of bactericide and 60 parts of protective rubber powder.

[0041] The dispersed phase includes 510 parts of deionized water, 2 parts of associative cellulose, 8 parts of hydroxyethyl cellulose, 9 parts of propylene glycol, 8 parts of titanium dioxide, 35 parts of kaolin, 1.5 parts of dispersant, 1.2 parts of foam suppressor, pH 1 part of conditioner, 2 parts of defoamer, 2.5 parts of preservative, 1.2 parts of wetting agent, 210 parts of pure acrylic emulsion and 40 parts of protective agent solution.

[0042] The continuous phase includes 220 parts of deionized water, 610 parts of silicon-acrylic emulsion, 35 parts of propylene glycol, 2 parts of defoamer, 2.5 parts of preservative, 2 parts of pH reg...

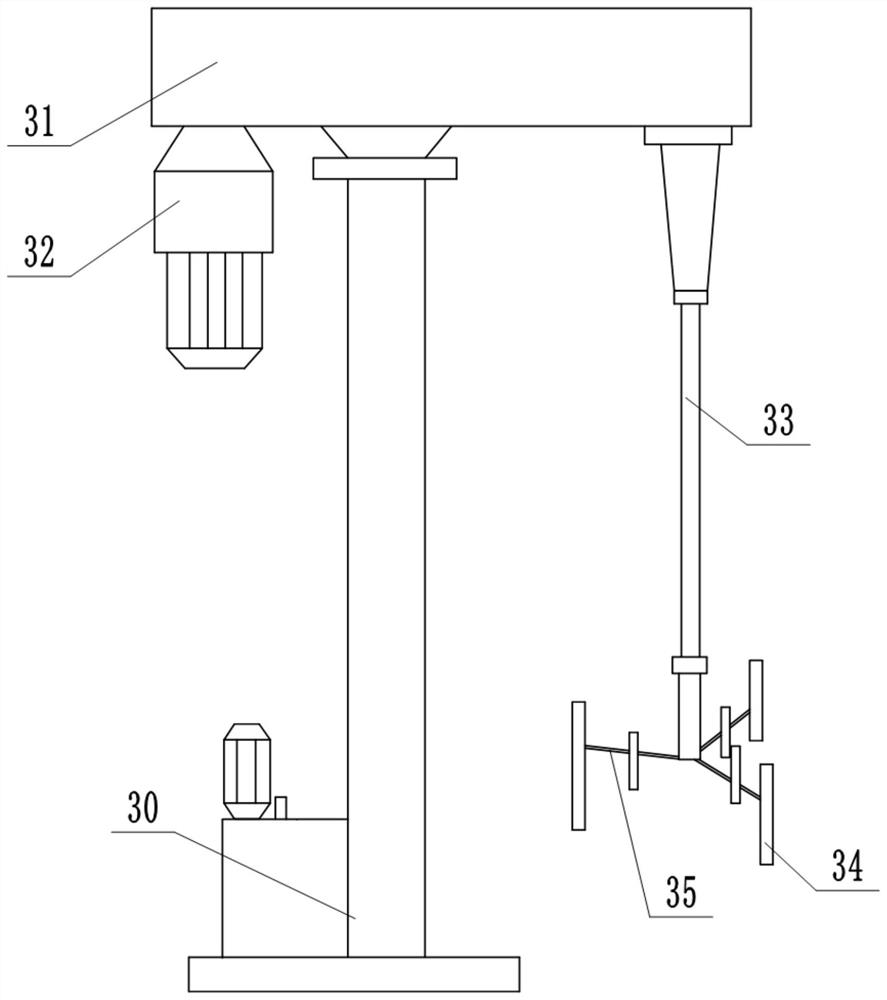

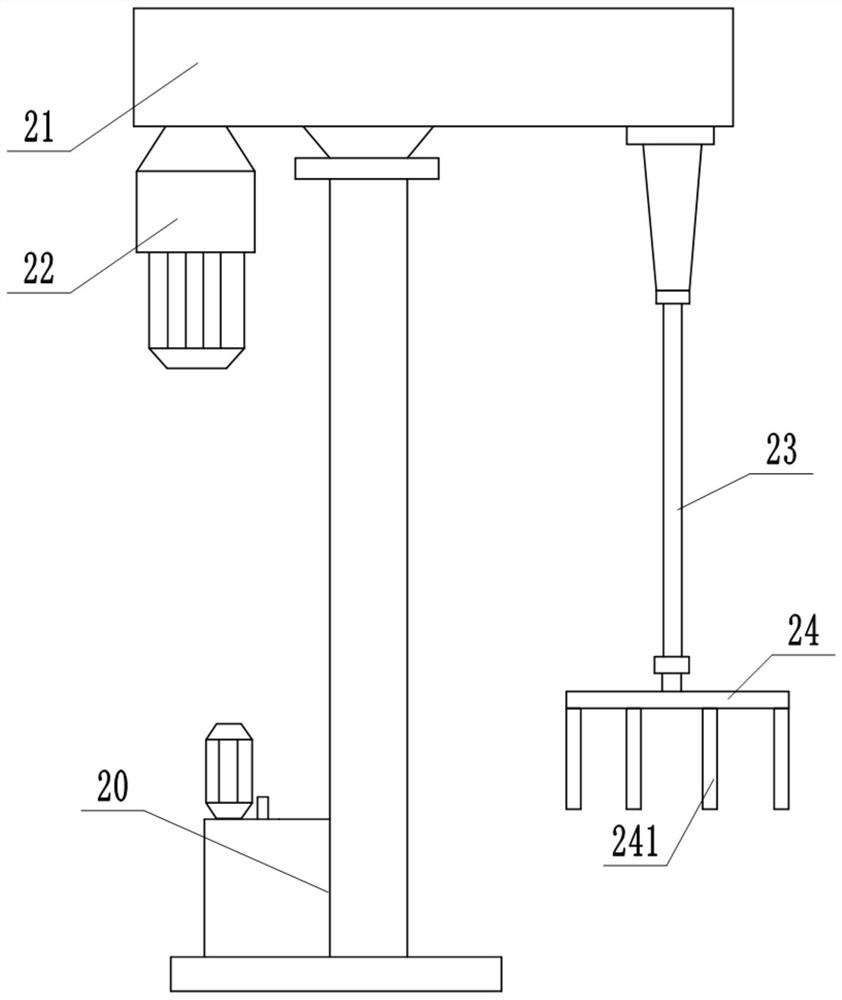

Embodiment 2

[0053] The difference between the present embodiment and the first embodiment is only that the processing equipment of the imitation stone paint is different from the first embodiment. In the present embodiment, the processing equipment of imitation stone paint comprises pre-cut net, vertical slicing disc, columnar stirring disc, hydraulic lifting platform, support platform and the motor fixedly installed on the support platform, and the aperture of pre-cut net is 2- 2.5cm. The supporting platform is fixedly installed on the hydraulic lifting platform, and the supporting platform can be moved up and down by operating the hydraulic lifting platform. The support table is rotatably connected with a rotating shaft, a driving wheel is fixed on the output shaft of the motor, a driven wheel is fixed on the rotating shaft, and a conveying belt is connected between the driving wheel and the driven wheel.

[0054] The vertical cutter disc includes 3 sets of cutter groups that are evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com