Waste tire whole tire continuous thermal cracking system and method

A waste tire and thermal cracking technology, which is used in special forms of dry distillation, petroleum industry, preparation of liquid hydrocarbon mixtures, etc. The effect of promoting adaptability, reducing energy consumption and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

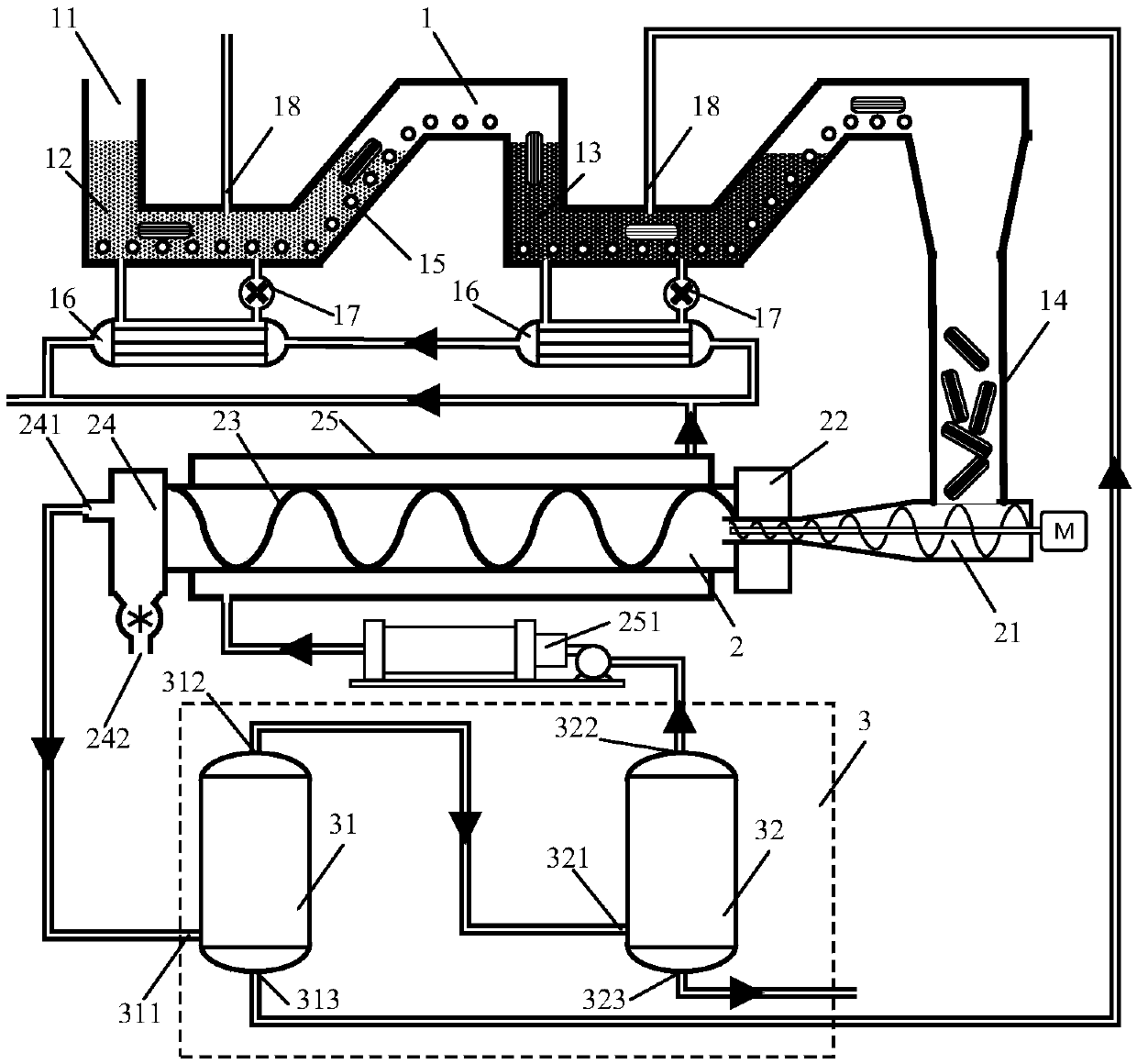

[0043] Such as figure 1 As shown, a whole-tire pyrolysis system for waste tires disclosed in this embodiment includes a circularly connected U-shaped preheater 1, a thermal cracking reactor 2 and a condensation system 3; the U-shaped preheater 1 There are discharge port 14, heat exchanger 16 and liquid replenishing pipe 18 on the top, and the thermal cracking reactor 2 includes a feed sealing screw 21, a rear support bin 24 and a hot blast heater 25, and the hot blast heater 25 A combustion furnace 251 is arranged on it, the rear support bin 24 includes a high-temperature oil and gas output port 241 and a carbon black sealed output port 242, and the condensation system 3 includes a heavy oil condensation tank 31 and a light oil condensation tank 32;

[0044] The discharge port 14 of the U-shaped preheating box 1 is connected on the feed sealing screw 21 of the thermal cracking reactor 2, and the diameter and pitch of the screw blade of the feed sealing screw 21 are imported to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap