A kind of bill paper and its manufacturing method

A manufacturing method and paper technology, which are applied in the directions of papermaking, papermaking, textiles and papermaking, can solve the problems of imitation and forgery of bill paper, and achieve the effect of improving anti-counterfeiting security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

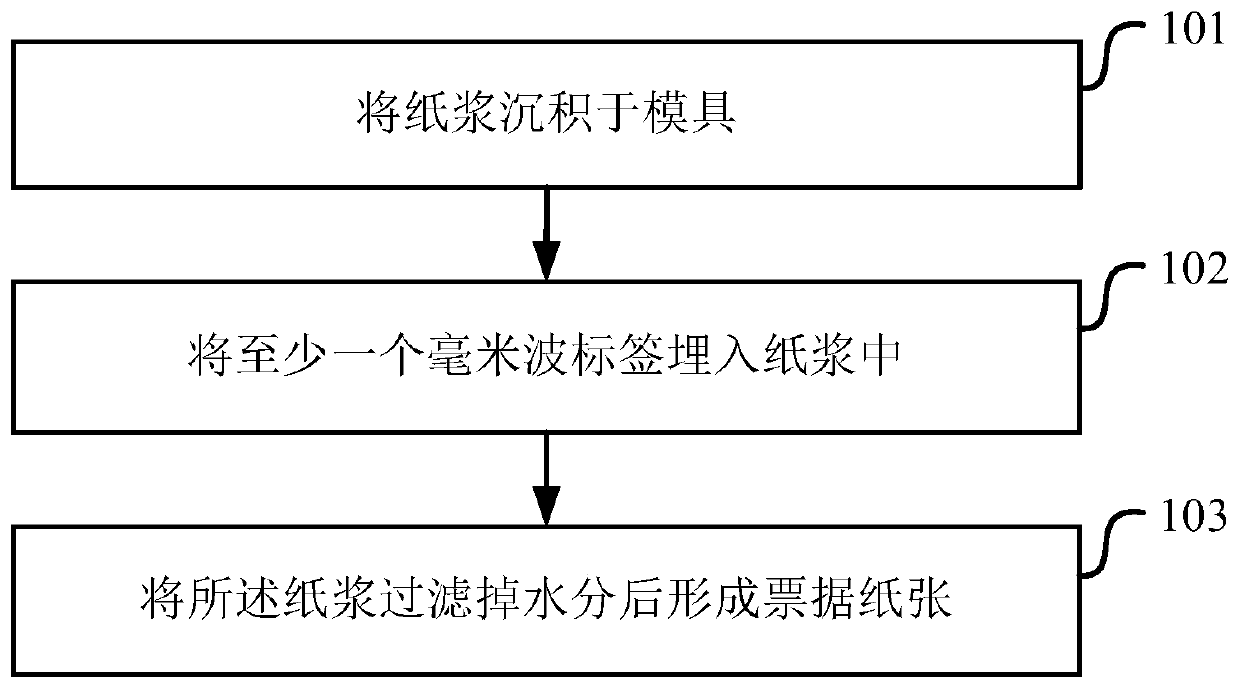

[0023] figure 1 It shows a schematic flow diagram of the implementation of the manufacturing method of the bill paper in the embodiment of the present application, as shown in the figure, including:

[0024] Step 101, depositing pulp on a mould;

[0025] Step 102, embedding at least one millimeter wave tag in pulp;

[0026] Step 103, filter the pulp to remove water, and then form a receipt paper.

[0027] During specific implementation, the mold may be a tool adapted according to different requirements such as the shape and thickness of the receipt paper.

[0028] The millimeter-wave label can be a millimeter-scale chip. After being added to the receipt paper, the receipt paper will not bulge or be felt by the user, and other characters or patterns can be printed on the receipt paper. Operations such as folding and rubbing the receipt paper will not damage the millimeter wave label.

[0029] The millimeter wave label can be pre-written with information, such as: codes with...

Embodiment 2

[0104] Based on the same inventive concept, an embodiment of the present application provides a receipt paper, which will be described below.

[0105] The receipt paper provided in the embodiment of the present application is manufactured by using the manufacturing method provided in the above-mentioned embodiment 1.

[0106]Specifically, an embodiment of the present application provides a ticket paper, and the ticket paper includes: a millimeter wave tag.

[0107] Since the bill paper provided by the embodiment of the present application adds a millimeter wave label, the anti-counterfeiting mark can be realized without being visible to the naked eye, and the user does not need to perform complex comparison and anti-counterfeiting distinction with the naked eye, and it is difficult for criminals to forge. It not only facilitates the user but also improves the anti-counterfeiting security.

[0108] In practice, the bill paper can be various bills such as banknotes (or banknote...

Embodiment 3

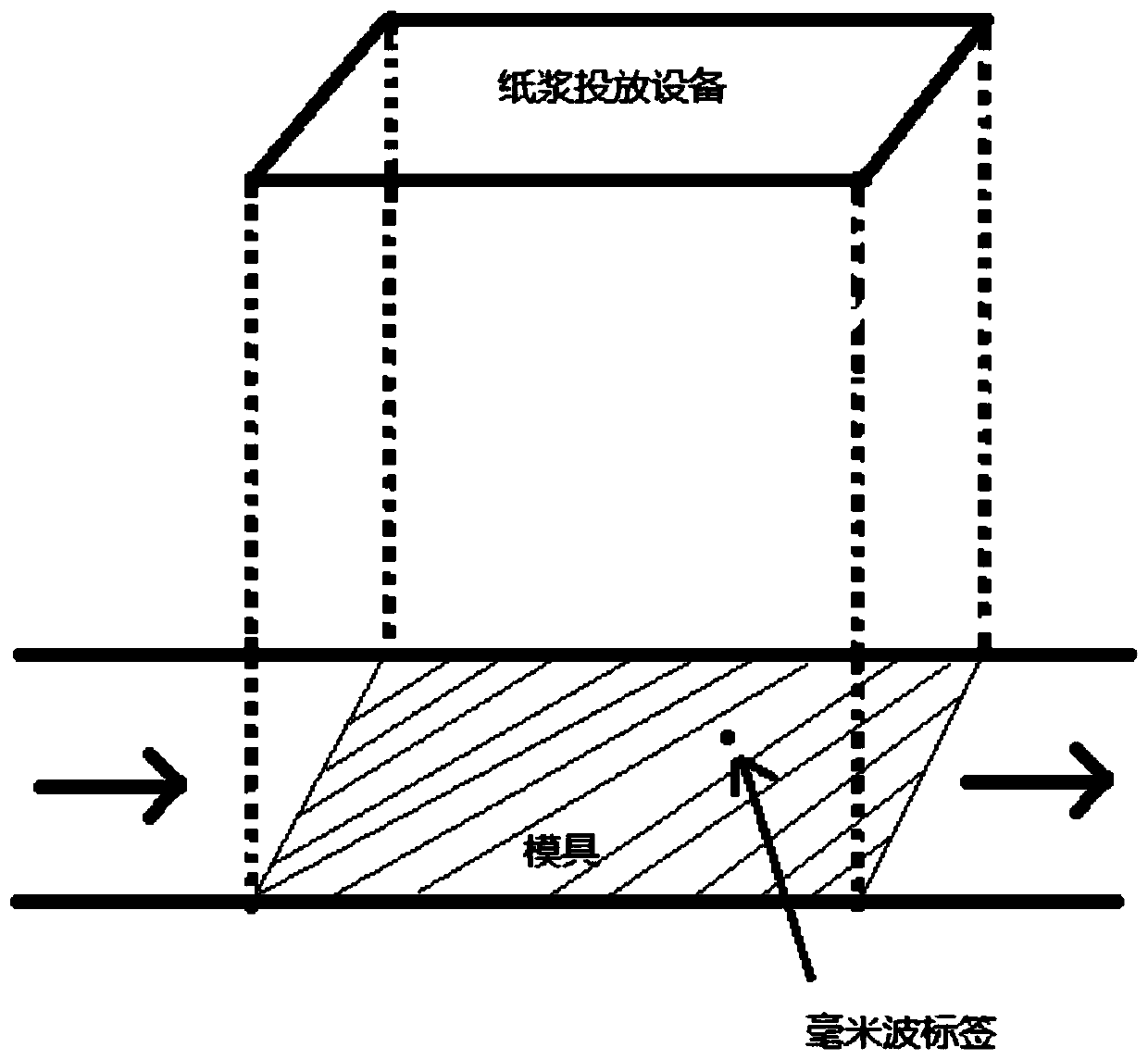

[0111] The embodiment of the present application uses the banknote manufacturing process as an example for illustration.

[0112] The existing banknote paper production process is usually as follows:

[0113] 1) Add water to cotton linters and stir to form a uniform pulp

[0114] 2) Papermaking

[0115] The mold (for example: a mold composed of 7*5 100 yuan banknotes) has a series of meshes, and the mesh at the watermark is larger than other places (making the water injection faster than other places to form a thicker watermark). Place a safety line at a certain position in each small mold in 7*5; randomly sprinkle ultraviolet (UV) phosphor lines at each small mold position; the mold belt (a strip composed of multiple large molds) moves in the pulp, Pulp water flows through the mesh in the mold from top to bottom, causing deposition. The water flow speed, the moving speed of the mold belt and the size of the mesh together determine the thickness and density of the deposited ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com