Device and method for automatically controlling excitation frequency of concrete pavement resonance crushing vehicle

An automatic control device and concrete pavement technology, applied in roads, roads, road repairs, etc., can solve problems such as hidden safety hazards, hidden dangers to the personal safety of observers, low work efficiency, etc., and achieve the goal of ensuring personal safety, high efficiency and low consumption of broken pavement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

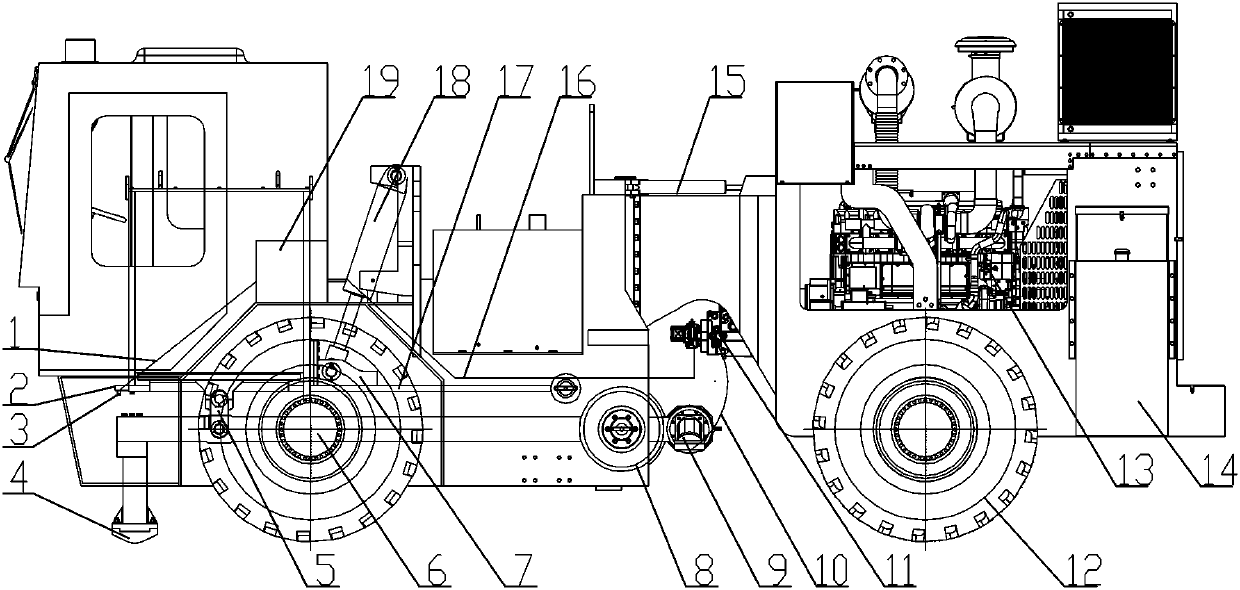

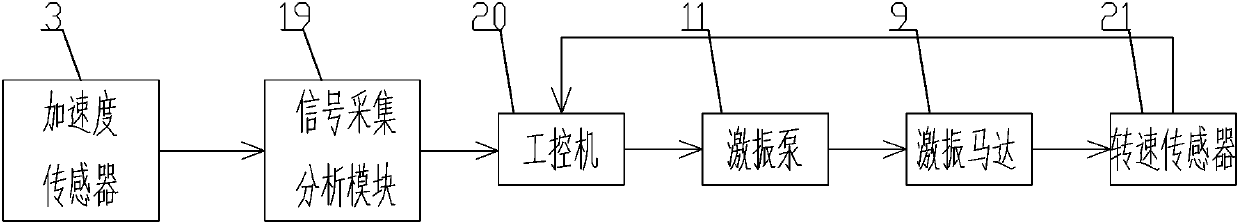

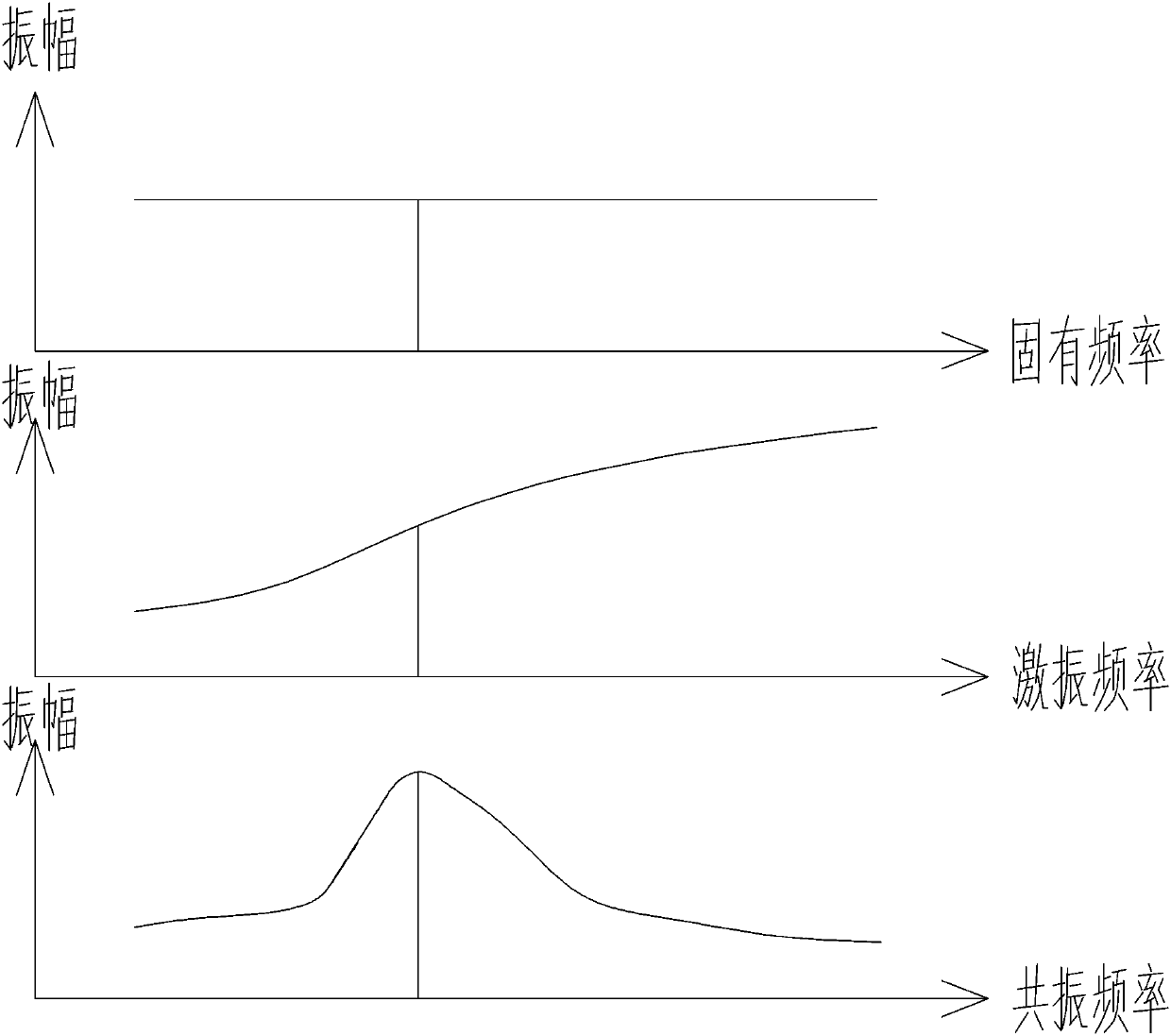

[0029] see Figure 1-4 , an automatic control device for the excitation frequency of a concrete road resonance crushing vehicle, which includes a crushing engineering vehicle body 15, an excitation device is installed on the front of the crushing engineering vehicle body 15, and the vibration excitation device includes an excitation beam Mounting frame 17, one end of the excitation beam mounting frame 17 is hinged on the crushing engineering vehicle body 15 through a pin shaft, the bottom of the excitation beam mounting frame 17 is equipped with an excitation beam 6 through the first hinge seat 5, One end of the head of the excitation beam 6 is equipped with an excitation hammer 4, and the other end is equipped with an excitation motor 9, and the vibration excitation motor 9 is connected with the excitation hydraulic pump 11, and the vibration excitation beam installation frame 17 The end is equipped with an acceleration sensor 3 for detecting the natural frequency of the road...

Embodiment 2

[0037] Adopt the control method of the automatic control device of excitation frequency of the concrete road surface resonance crushing vehicle described in any one, it comprises the following steps:

[0038] Step1: Detect the natural frequency of the road surface; the operator will clean up the area where the acceleration sensor 3 needs to be placed on the road surface to be tested to ensure that the area to be tested is clean and smooth; place the acceleration sensor 3 on the road surface to be tested to ensure that the acceleration sensor 3 is in line with the road surface to be tested full contact;

[0039] Step2: Turn on the resonance crushing vehicle and manual work control mode, use the vibration hammer 4 on the vehicle to hit the concrete road surface, and then collect the acceleration signal after the vibration of the concrete road surface through the acceleration sensor 3, and pass the signal through the first signal line 1 is transmitted to the signal acquisition an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com