A multi-mode shield machine

A shield machine and multi-mode technology, applied in mining equipment, tunnels, earthwork drilling and mining, etc., can solve the problems of increased construction period and increased project investment, and achieve strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

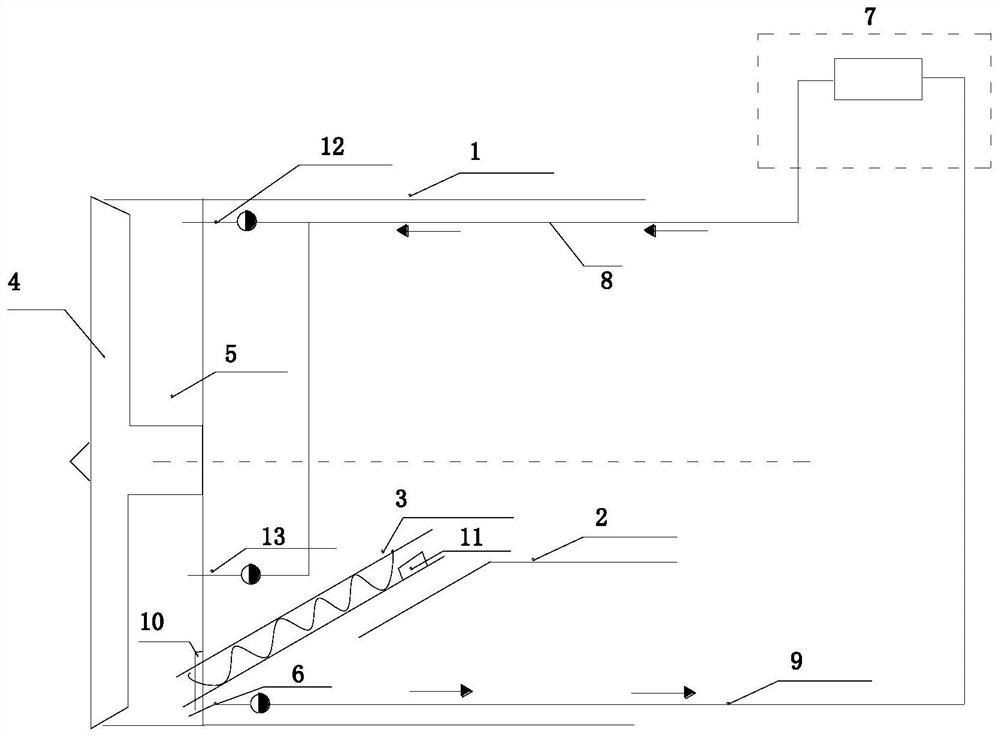

[0022]This embodiment provides a multi-mode shield machine, including a shield shell 1, a belt conveyor 2, a screw conveyor 3, a mud circulation system and a cutter head 4; the belt conveyor 2 and the screw conveyor 3 are arranged in the In the shield case 1, the cutter head 4 is provided at the front end of the shield case 1, and a sealed compartment 5 is provided between the cutter head 4 and the front end of the shield case 1; The mud inlet and the mud outlet 6, the mud circulation system includes an external mud source 7, a mud inlet pipe 8 and a mud outlet pipe 9; one end of the mud inlet pipe 8 is connected to the mud inlet through the mud The other end of the sealed cabin 5 is connected to an external mud source 7; one end of the slurry outlet pipe 9 is connected to the sealed cabin 5 through the slurry outlet 6 and the other end is connected to an external mud source 7; The slag inlet of the screw conveyor 3 is connected to the sealed cabin and closed by an openable slag inl...

Embodiment 2

[0030]This embodiment provides a method for using the multi-mode shield machine described in Embodiment 1, specifically:

[0031]When the ground is soft ground or uneven ground, and the ground environment is relatively simple, the earth pressure mode is adopted: the soil pressure in the sealed cabin is used to balance the water and soil pressure on the face of the tunnel, and the muck cut by the tool enters the seal Inside the cabin; the slag inlet gate of the screw conveyor is opened, and the slag is transported from the slag inlet of the screw conveyor to the slag outlet of the screw conveyor located inside the shield shell, and falls on the belt conveyor through the slag outlet. It is transported to the outside of the shield shell through a belt conveyor; at this time, the mud circulation system stops working. The cutting tool can be matched with a cutting knife and a hob according to the ground conditions, and the cutter head adopts a low speed mode (0-2.24r / min) for excavation.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com