A mud pipe extension device and its construction method

A mud pipe and slurry feeding technology, which is used in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of poor versatility and strong pertinence, and achieve the effects of simple operation, strong versatility and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

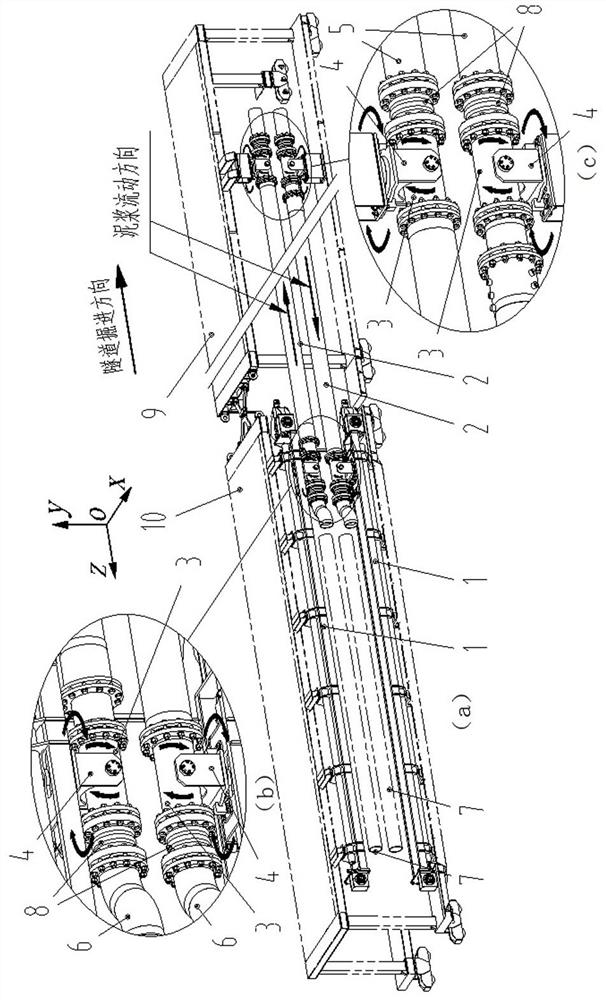

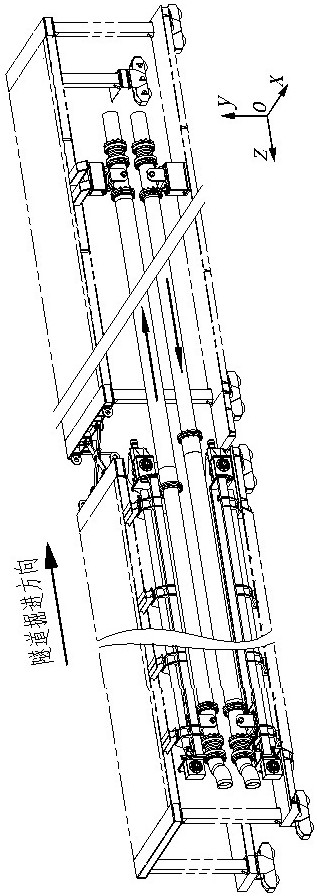

[0046] Embodiment 1. When using the present invention, the slurry shield machine includes the same upper and lower sets of mud pipe extension devices, which correspond to the slurry feeding system and the slurry discharge system respectively. The following takes one of the extension devices as an example to illustrate, and simultaneously establishes Such as figure 1 In the Cartesian coordinate system shown, the negative direction of the z-axis is the same as the tunneling direction.

[0047] The mud pipe extension device consists of the following modules: drive mechanism 1, telescopic pipe 2, hinged pipe 3, hinged mechanism 4, trailer mud pipe 5, tunnel mud pipe 6, extension pipe 7, expansion joint 8, trailer one 9, trailer two 10 , the first trailer 9 and the second trailer 10 are hinged to provide a fixed platform for the entire mud pipe extension device. In addition, during tunnel excavation, uphill, downhill and horizontal turning conditions are often encountered, such as...

Embodiment 2

[0053] Embodiment 2, a construction method of a mud pipe extension device, including the tunneling state of the shield machine and the extension state of the mud pipe:

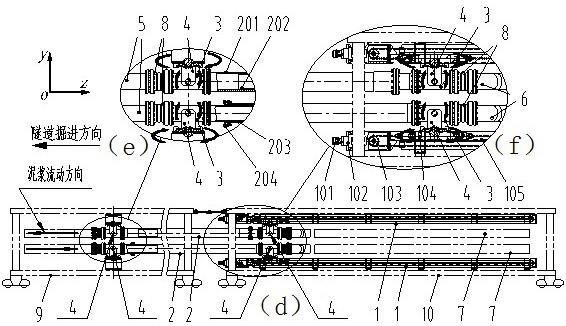

[0054] (1) Tunneling state of the shield machine: the driving mechanism 1 does not provide power, the driving trolley 104 and the hinged pipe 3 connected to it are stationary relative to the inner wall of the tunnel, but the driving trolley 104 and the hinged pipe 3 connected to it are relative to the trailer one 9 and the two trailers The z axis moves in the positive direction. At the same time, the inner cylindrical section 202 of the telescopic tube 2 is gradually pulled out relative to the outer cylindrical section 201 .

[0055] (2) Mud pipe extension state: when the inner cylinder section 202 in the telescopic pipe 2 reaches the full stroke state relative to the outer cylinder section 201, as attached figure 2 , Figure 4 As shown, it is necessary to stop the tunneling of the shield machine. The tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com