High precision smooth compensation control method for liquid phase pump

A technology of smooth control and compensation control, applied in pump control, control system, motor control, etc., can solve problems such as increased pulsation rate, decreased accuracy of liquid phase pump, and affected the stability of cylinder block operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

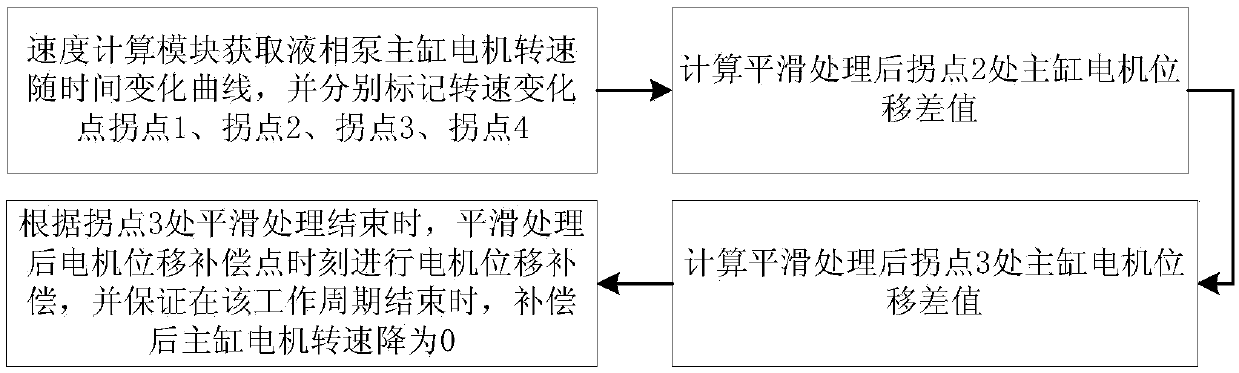

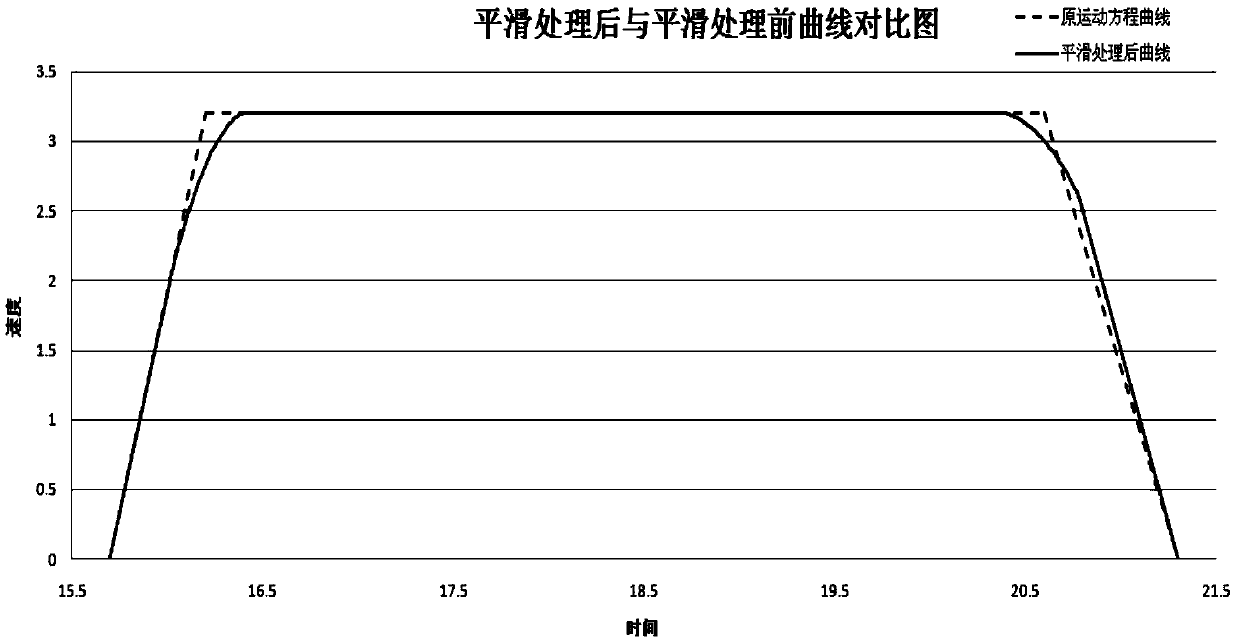

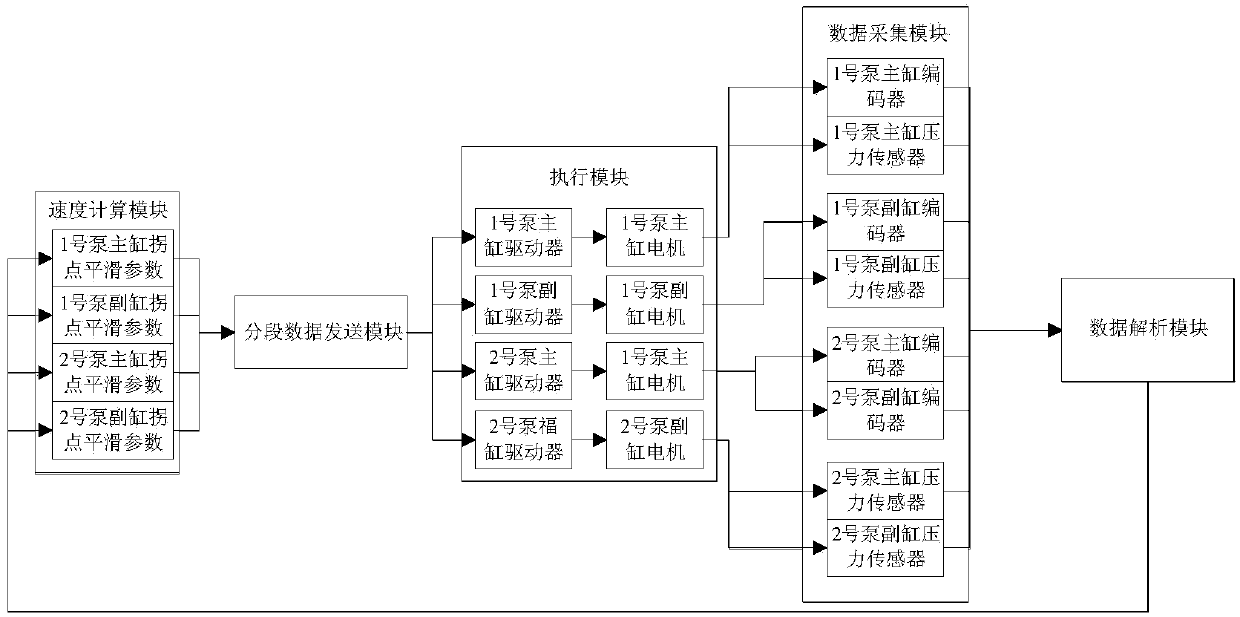

[0062] A high-precision smooth compensation control method for liquid-phase pumps. Through the smoothing algorithm, the No. 1 pump and the No. 2 pump can instantly and smoothly transition to 0-acceleration motion during high-acceleration motion without jittering; The body speed is compensated in real time, so that the total displacement of the pump body remains unchanged, such as figure 1 As shown, the specific steps are as follows:

[0063] (1) The preset motor starts the working process of the motor of the main cylinder of the liquid phase pump. In a single working cycle, the motor speed of the main cylinder of the liquid phase pump is satisfied from uniform acceleration to uniform speed to uniform deceleration. The speed calculation module obtains the motor of the main cylinder of the liquid phase pump Speed change curve with time, and mark the speed change points inflection point 1, inflection point 2, inflection point 3, inflection point 4;

[0064] Inflection point 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com