Track type movable blade stepless variable frequency pump

A movable vane, variable frequency pump technology, applied in rotary piston/swing piston pump components, rotary piston pumps, pumps, etc., can solve the problems of impeller vulnerable to cavitation damage, volumetric efficiency drop, pump efficiency drop, etc. , to achieve the effect of easy processing, manufacturing and installation, increasing flow volume ratio, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

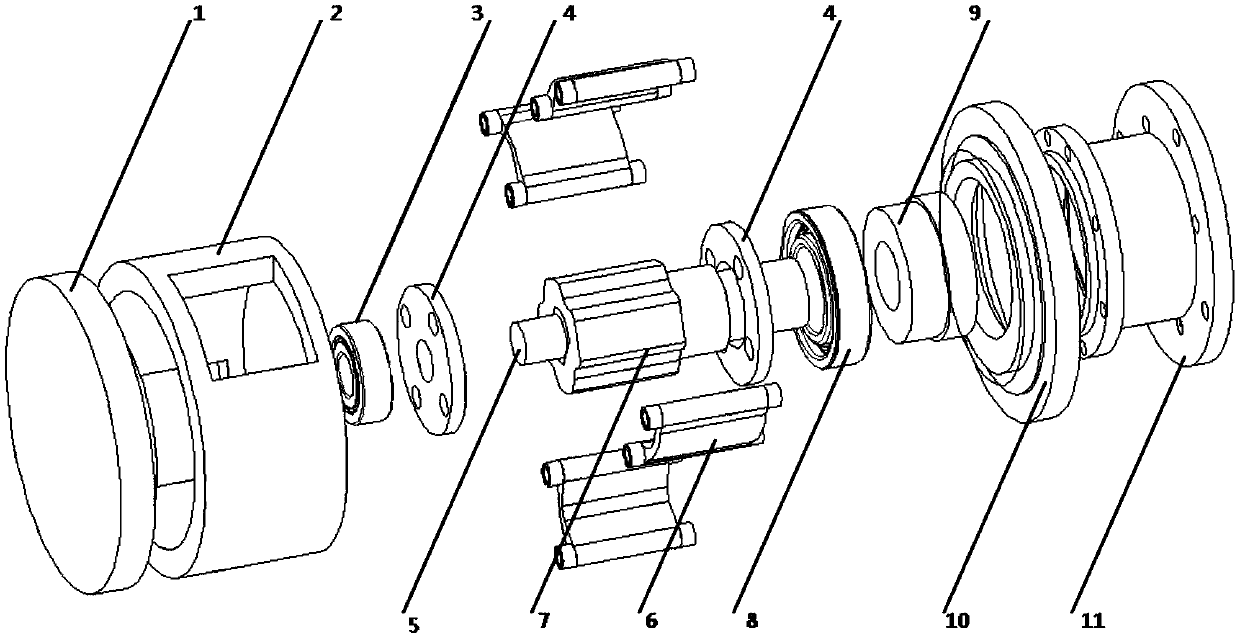

[0024] Such as figure 1 As shown, this embodiment provides a track-type movable vane stepless frequency conversion pump, including a bottom end cover 1, a pump casing 2, bearings 3, 8, a vane positioning plate 4, a pump shaft 5, movable vanes 6, a rotor 7, Mechanical seal 9, upper end cover 10 and online flange 11.

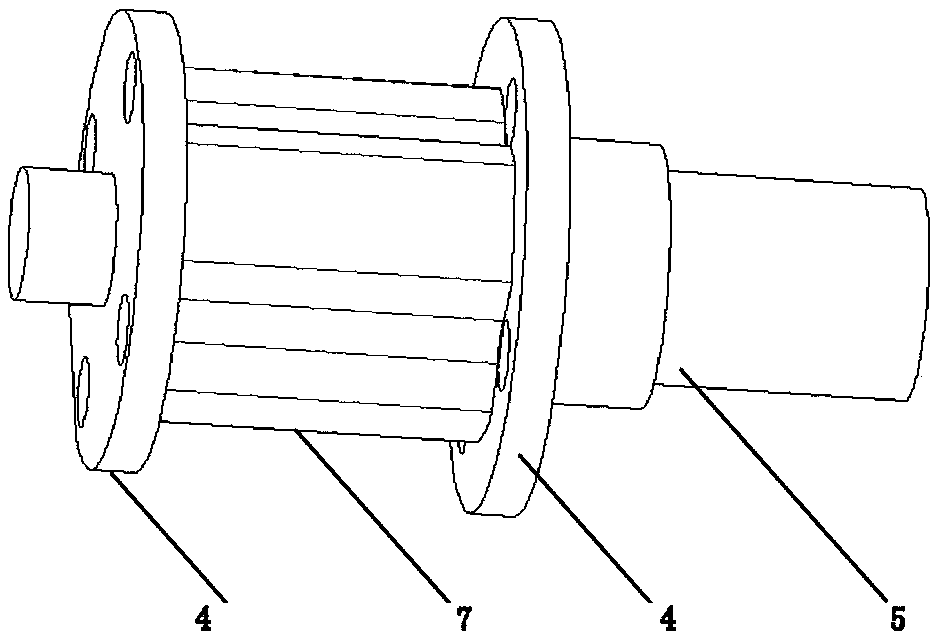

[0025] Such as figure 2 As shown, the blade positioning plate 4 and the rotor 7 are screwed on the pump shaft 5 to form a pump rotor, and are connected to the output shaft of the motor, and the motor provides power to drive the pump rotor to rotate throughout the circle.

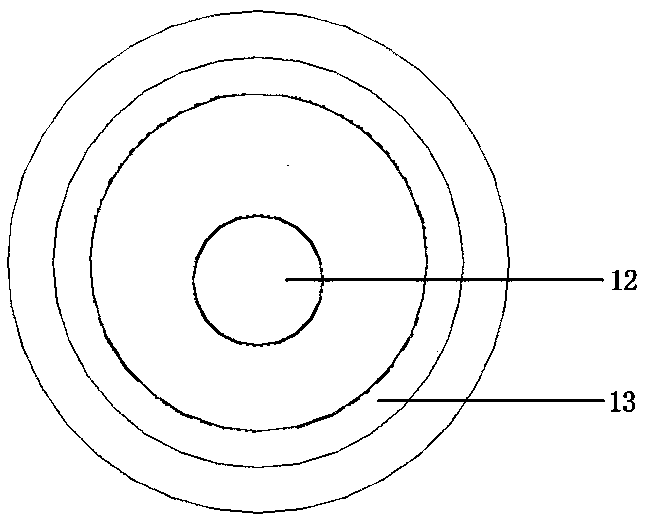

[0026] Such as image 3 As shown, the inner surfaces of the bottom end cover 1 and the upper end cover 10 are provided with bearing recesses 12 and rail grooves 13 .

[0027] Such as figure 1 As shown, the two ends of the pump rotor are closely connected to the bearing recesses 12 of the bottom end cover 1 and the upper end cover 10 through the bearings 3, 8 and the mechanical seal 9 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com