Primary draught fan automatic parallel method and system for thermal generator set

A thermal power generation unit and secondary fan technology, applied in the direction of machines/engines, mechanical equipment, pump control, etc., can solve problems such as low primary air pressure, deterioration of boiler combustion stability, and boiler parameter imbalance, so as to reduce fan stall and solidify parallel Fan process, the effect of reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Taking a certain 600MW coal-fired power plant boiler as an example, the method for automatically paralleling the primary air for generating sets of the present invention is further described in detail.

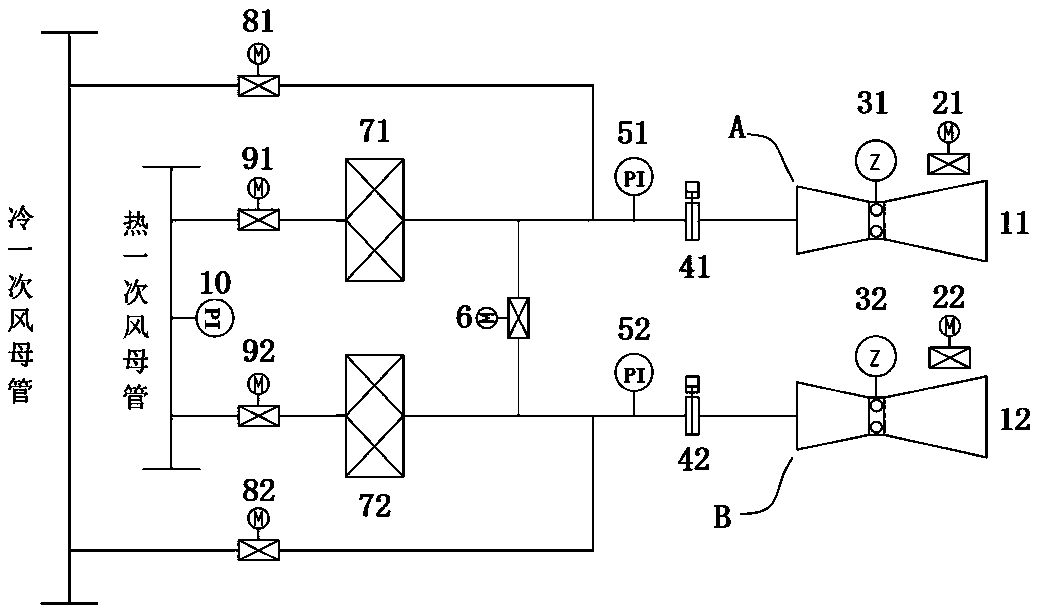

[0037] Such as figure 1As shown, the primary fan automatic parallel system used in the thermal power generation unit in this embodiment includes two parallel primary fans 1 (primary fan 1#1, primary fan 1#2) and computer control equipment (omitted in the figure), the primary fan The air outlet of 1 is connected with an outlet damper 4, and the output end of the outlet damper 4 is connected through the air preheater 7, the hot primary damper 9 and the hot primary air main pipe, and the other way is through the cold primary air door 8 and the cold primary air main pipe connected. Taking primary fan 1#1 as an example, the air outlet of primary fan 1#1 is connected to outlet damper 4#1, and the output end of outlet damper 4#1 passes through air preheater 7#1 and hot primar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com