A high-precision three-floating gyroscope active magnetic levitation system

A magnetic levitation and gyroscope technology, applied in gyroscope/steering sensing equipment, gyro effect for speed measurement, instrument and other directions, can solve the problem of low precision, achieve high precision, reduce interference torque, and improve the effect of gyroscope accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

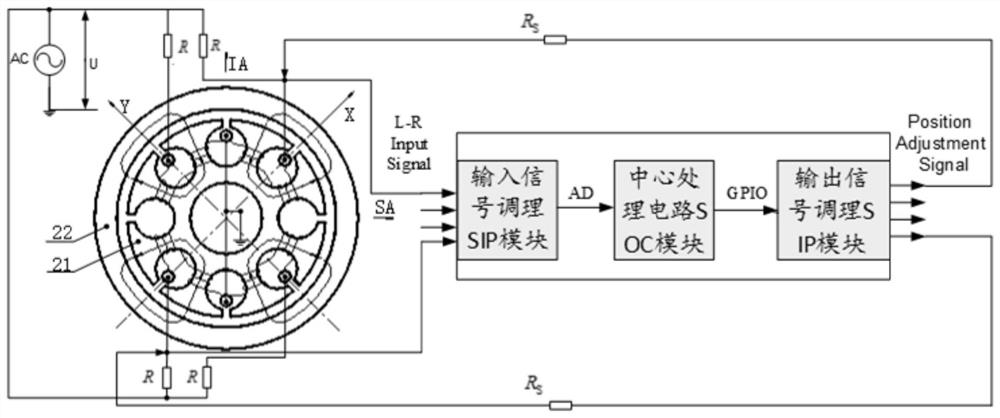

[0053] from figure 2 It can be seen that the high-precision three-float gyroscope active magnetic levitation system of the present invention consists of four parts: the electromagnetic element part, the input signal conditioning SIP module, the central processing circuit SOC module and the output signal conditioning SIP module.

[0054] Electromagnetic component part

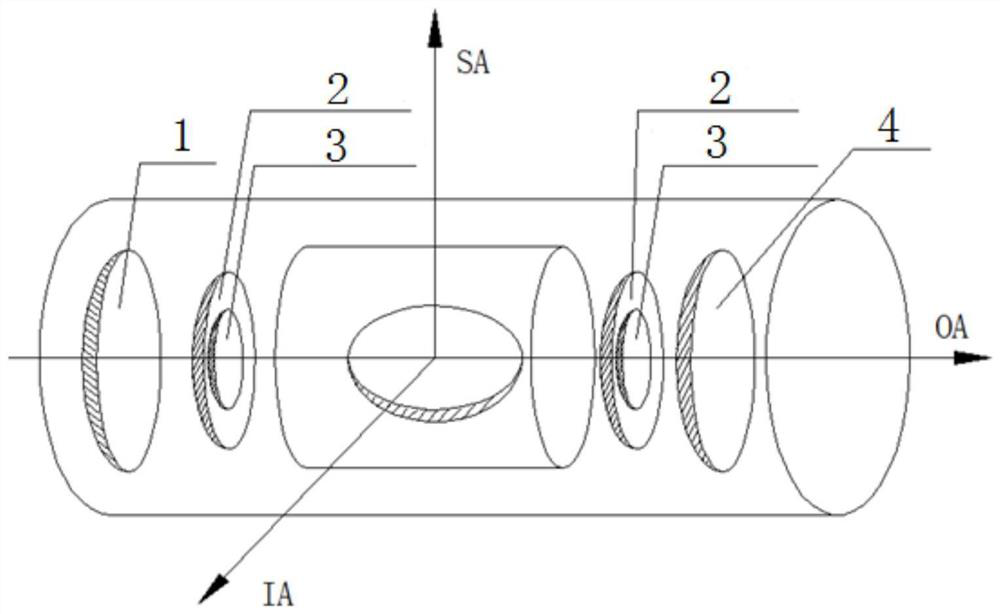

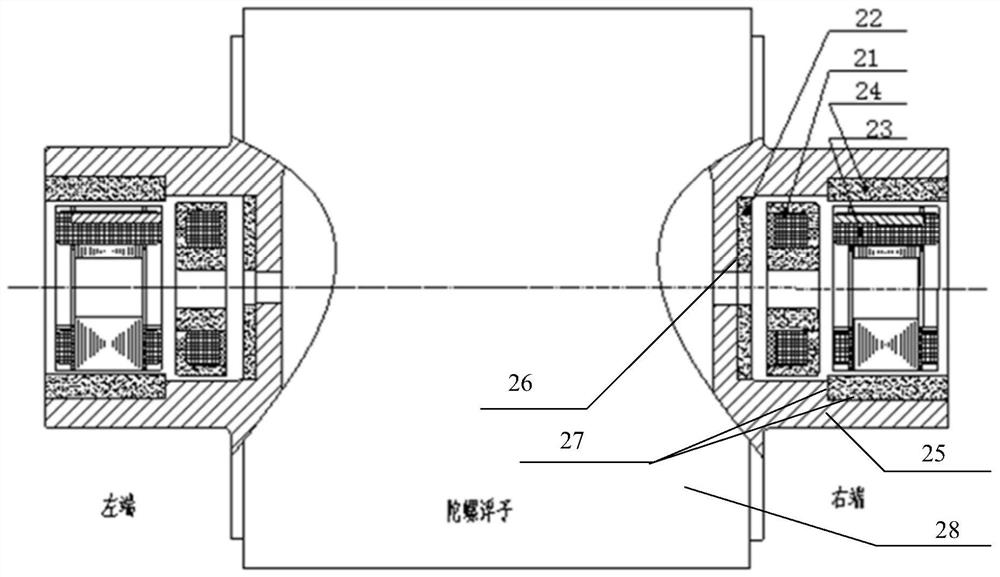

[0055] The suspension environment of the three-floor gyro float is a special environment with confined space, large damping, and small shaft-to-diameter ratio. -10 Within N.m.

[0056] The invention provides a reasonable arrangement mode, the radial and axial elements are separated and symmetrically "serialized" at the left and right ends of the float, which is helpful for saving the space size of the gyroscope, improving the manufacturability of element manufacturing and inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com