Heat Exchangers for Boilers

A technology of heat exchangers and condensing boilers, applied in heat exchange equipment, heat exchangers, water heaters, etc., can solve the problems of not explaining the method of production or installation, difficult to produce, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

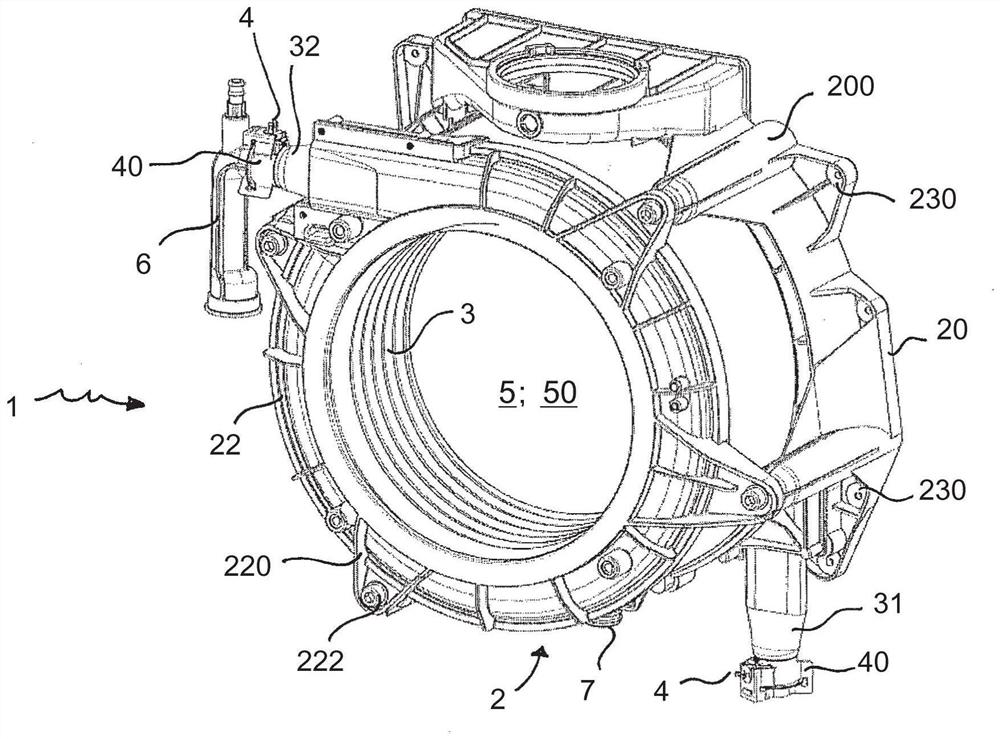

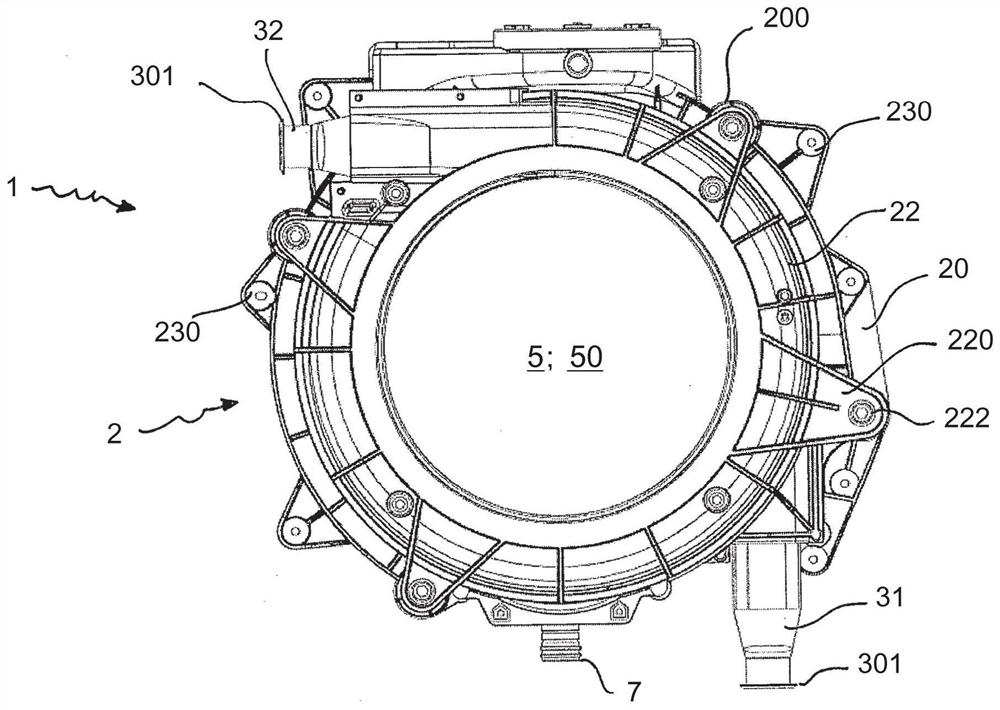

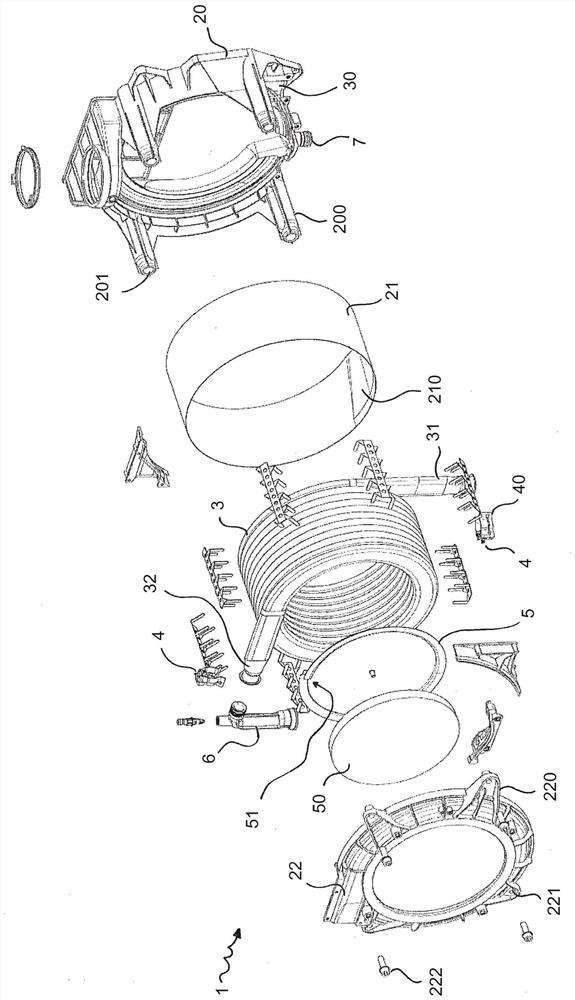

[0044] The heat exchanger 1 , hereinafter referred to simply as the exchanger 1 , comprises a suitable vessel body 2 , at least one coil and at least one temperature sensor device 4 .

[0045] The term "coil" means a bundle 3 of tubes, preferably metallic, wound helically around a central axis, adapted to form a suitable number of turns, and delimiting a combustion chamber 300 in which the combustion chamber 300 is introduced. Smoke produced by a device (not shown).

[0046] Said coil is advantageously made as a single piece, ie it is defined by a seamless single element.

[0047] Consequently, the coil has no welds and / or joints; this favors a uniform and homogeneous deformation due to the temperatures it is subjected to.

[0048] The coil is provided with at least a first end 31 serving as an inlet for a heat transfer fluid to be heated and at least a second end 32 serving as an outlet for said heat transfer fluid .

[0049] According to a preferred variant, said coil has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com