Cabbage vegetable harvester

A harvester and vegetable technology, which is applied in the field of agricultural machinery, can solve the problems of easily damaged cabbage, poor adaptability, and difficult adjustment of the height from the ground, and achieve the effect of high-quality cabbage harvest, reasonable combination, and compact connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

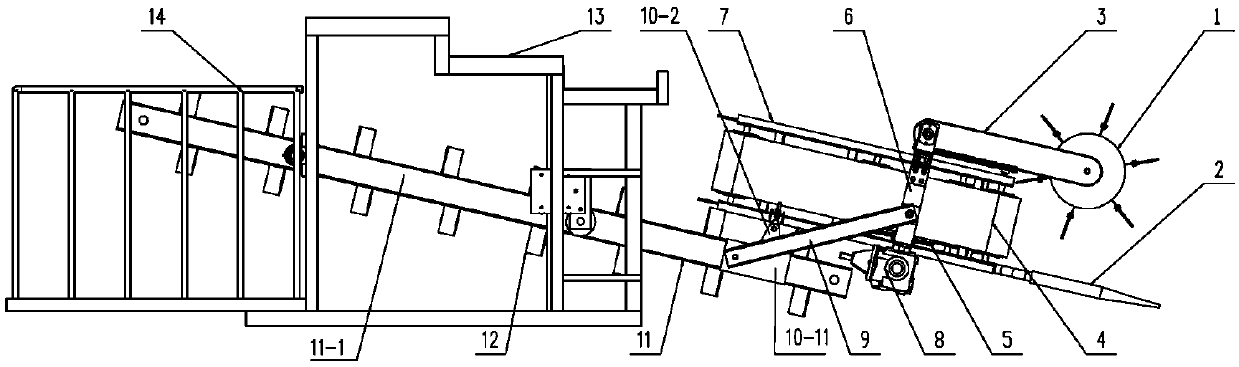

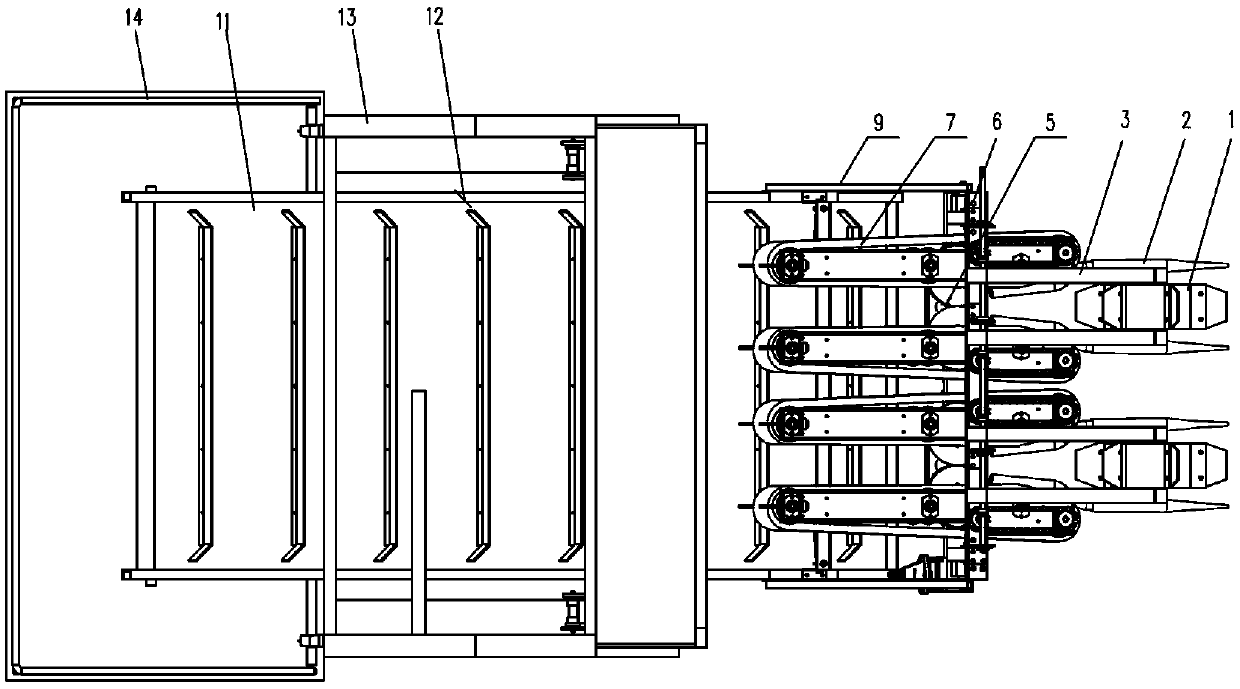

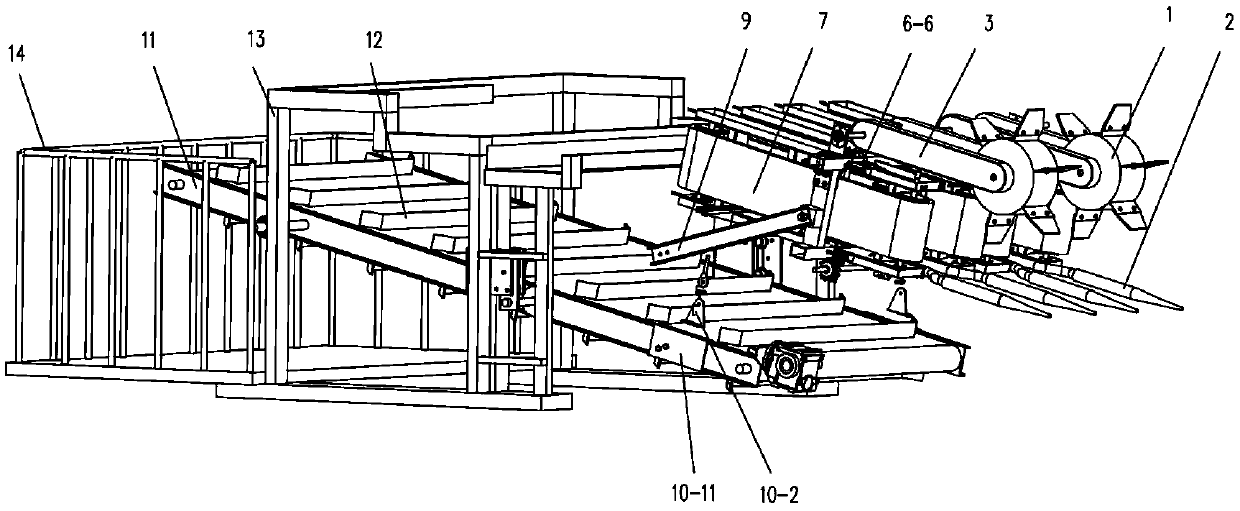

[0024] The basic structure of the present embodiment cabbage vegetable harvester is as follows: figure 1 , figure 2 with image 3 Shown, the chassis frame 13 of frame structure is equipped with the inclined frame 11-1 that supports front low rear high platform type conveyor belt 11, and this platform type conveyor belt 11 is distributed with baffle plate 12 at intervals, and its rear end is equipped with and chassis The collecting box 14 that frame is fixedly connected. The front section of inclined frame 11-1 supports header by bearing 10-11. The frame-shaped header frame 6 top and the bottom of the header middle part are respectively equipped with forward-extending dial wheel installation frame 3 and extracting mechanism 2. The rear end of the extraction mechanism 2 is equipped with a double-disc root-cutting mechanism 5 and an entrainment-type conveying mechanism 4 positioned on the double-disc root-cutting mechanism.

[0025] The dial wheel installation frame 3 is can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com