Tea leaves flattening apparatus

A technology for tea and mounting rods, which is applied in the field of tea, can solve the problems of low work efficiency, high labor intensity, poor stability, etc., and achieve the effect of simple structure, reasonable design, and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

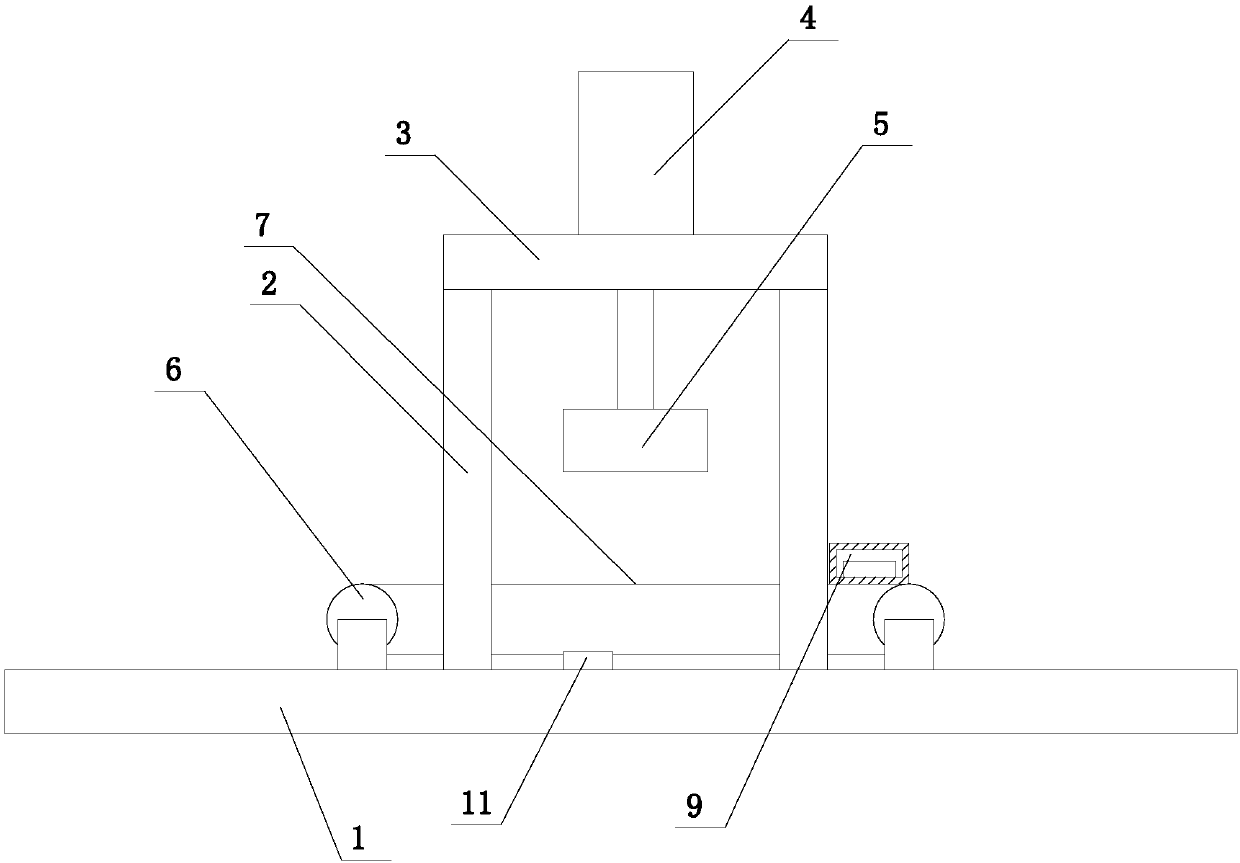

[0011] Such as figure 1 As shown, a tea flattening device includes a cuboid base 1, the upper surface of the base 1 is symmetrically provided with support rods 2, the tops of the two support rods 2 are provided with mounting rods 3, and the tops of the mounting rods 3 are provided with pressing rods. The flat motor 4, the output shaft of the flattened motor 4 passes through the installation rod 3, the lower end surface of the output shaft of the flattened motor 4 is provided with a punch mounting plate 5, and the upper surface of the base 1 is also provided with a conveyor belt 7 through a transmission shaft 6 , the upper surface of the conveyor belt 7 is provided with a die mounting block 8, the die mounting block 8 has a mounting groove 9 inside, and a weight sensor 10 is provided in the mounting groove 9, and the upper surface of the base 1 is connected to the punch mounting plate 5 The corresponding position is provided with a displacement sensor 11, and the upper surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com