Quick-release marking device for auto parts

A kind of auto parts and quick-installation technology, applied in the field of mechanical processing, can solve the problems of increasing the complexity of mechanical actions, increasing the lifting distance of the wheel hub, increasing the operating space, etc., to protect the laser head, increase the disassembly speed, and simplify the loading operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

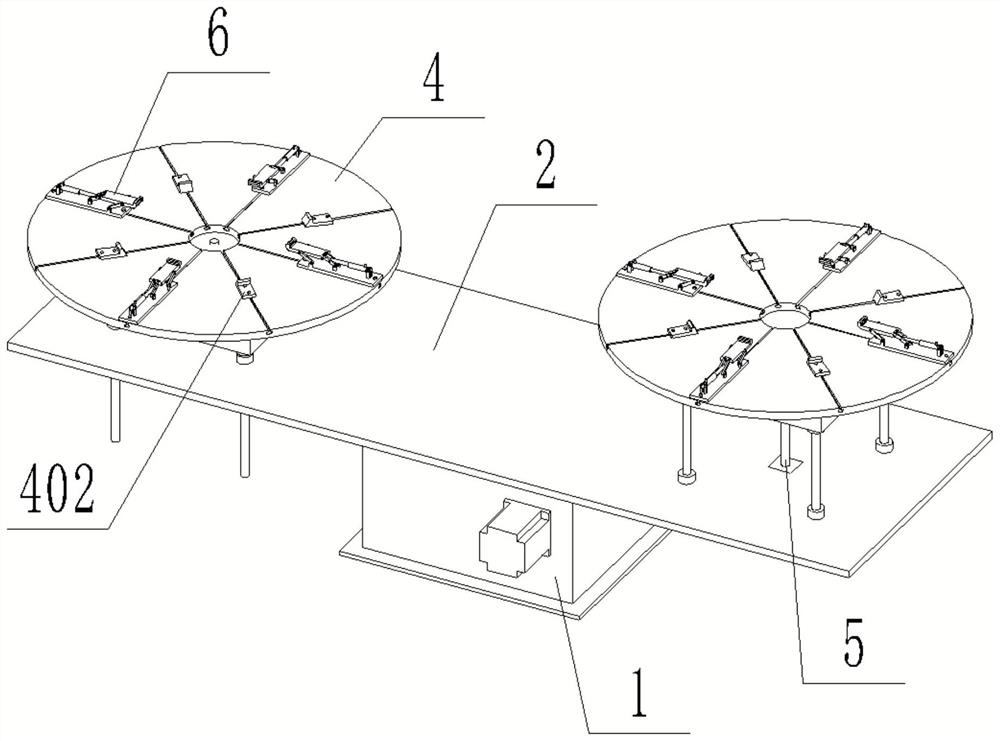

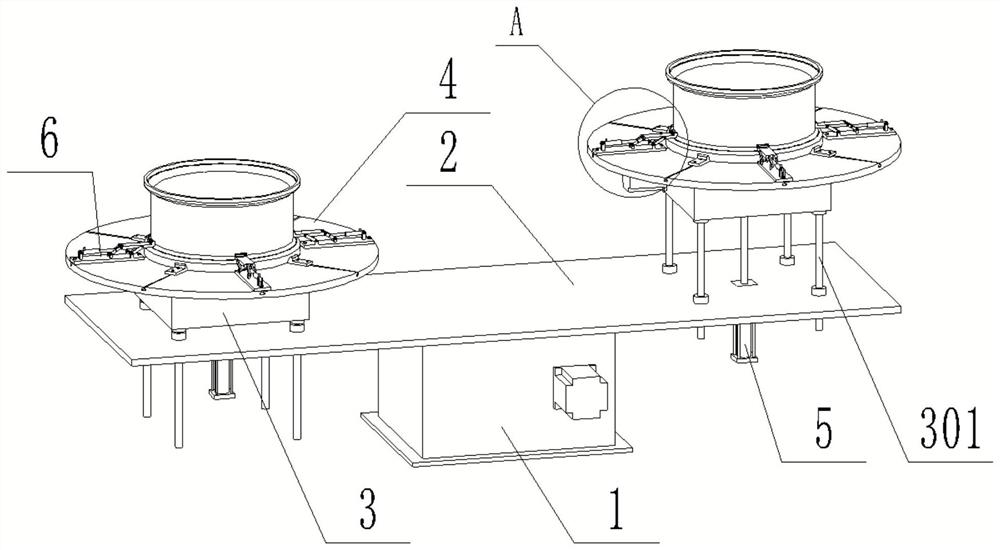

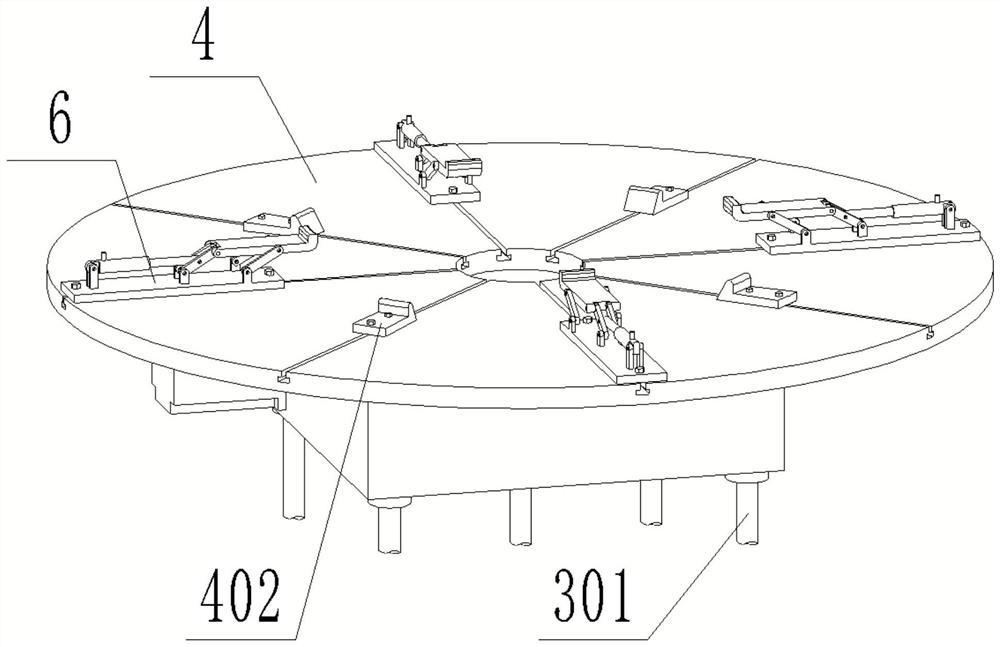

[0030] as attached figure 1 to attach Figure 8 Shown:

[0031] The present invention provides a quick-mounted marking device for auto parts, including: a base 1, a station conversion table 2, a station conversion turbine and worm transmission mechanism 201, a lifting seat 3, a circular guide rail 301, a rotary table 4, Rotary worm drive mechanism 401, coarse positioning block 402, lifting cylinder 5, compactor 6, compacting plate 601, connecting rod 602, compacting cylinder 603 and compacting base 604; the upper end surface of the base 1 is axially connected with a A set of station transfer table 2; the left and right sides of the station transfer table 2 are slidingly connected with a group of rotary table 4; the left and right sides of the station transfer table 2 are fixedly connected with a group of lifting cylinders 5; The bottom surface of the table 4 is fixedly connected; the upper end surface of the rotary table 4 is evenly arranged and tightly connected with four s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com