Two-way reverse self-cleaning vacuum pouring system

A vacuum pouring, self-cleaning technology, applied in household components, dispersed particle filtration, applications, etc., can solve the problems of filter and vacuum pump scrap, filter clogging, product quality, enterprise loss, etc., to reduce cleaning times, good benefits, The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

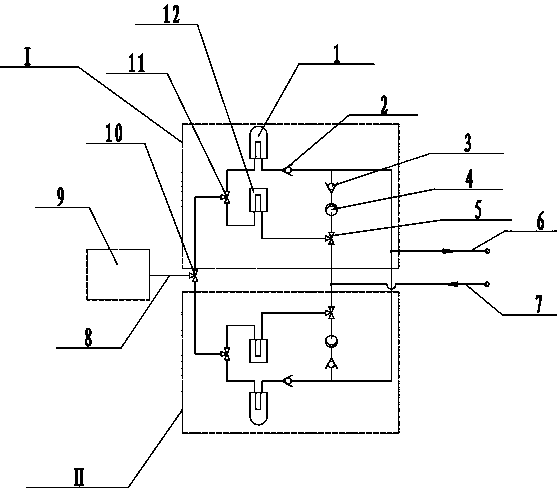

[0013] as attached figure 1 The shown two-way reverse self-cleaning vacuum pouring system is composed of the first filter mechanism I, the second filter mechanism II, the intake three-way valve 10, the intake pipe 8, the exhaust pipe 6 and the reverse compression air pipe 7 , the first filter mechanism I and the second filter mechanism II are arranged in parallel, the two interfaces of the three-way valve 10 of the intake pipe are respectively set at the inlets of the first filter mechanism I and the second filter mechanism II, and the three-way valve of the intake pipe 10 The other interface communicates with the intake pipe 8, the outlets of the first filter mechanism I and the second filter mechanism communicate with the exhaust pipe 6, and the side ports of the first filter mechanism I and the second filter II communicate with the reverse compres...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap