High-efficiency film coating machine for solar thermal-collecting tubes

A solar collector tube, coating machine technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of low space utilization rate of vacuum chamber, low equipment capacity, etc., to reduce production costs and Low energy consumption cost, small equipment cost, small increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

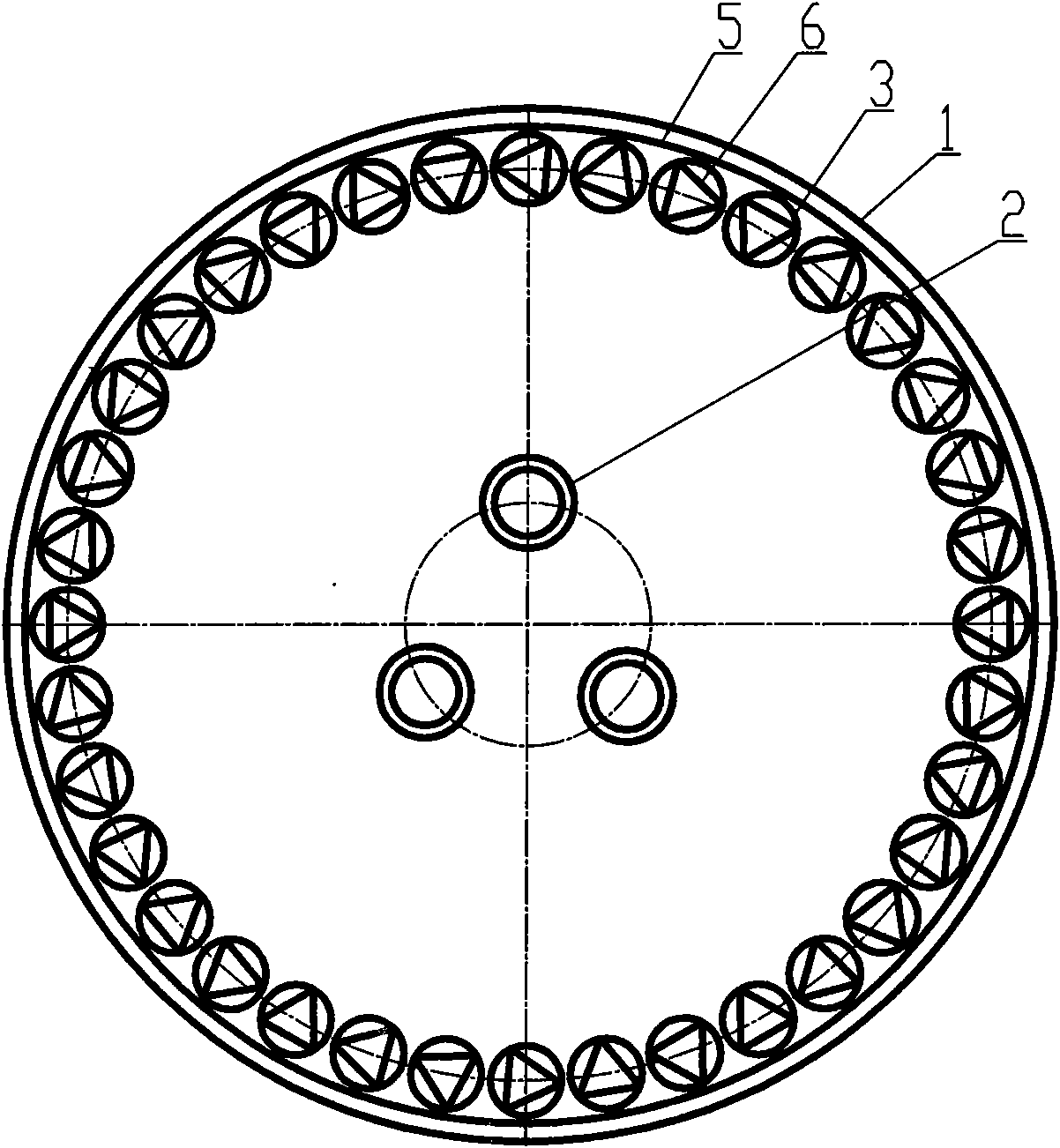

[0032] refer to figure 2 , a high-efficiency solar collector tube coating machine, including a vacuum chamber 1, a target 2, a turntable 5 and a clamp 6, the vacuum chamber 1 is a cylindrical cylinder, the cylindrical cylinder has a door, and the target The pole 2 is a cylindrical elongated part that rotates around its axis, the target pole 2 is located in the center of the turntable 5, the turntable 5 is located in the vacuum chamber 1, and the solar heat collector workpiece 3 is clamped on the fixture 6 , the clamp 6 is connected with the driving device through the rotation motion transmission chain, and the turntable 5 is connected with the driving device through the revolution motion transmission chain, and the high-efficiency solar collector tube coating machine also includes 12 turntables 4; all the clamps 6 are installed On the turntable 4; there are two arrangement modes of n=5 clamps 6 and n=4 clamps 6 on the turntable 4; The revolution transmission chain is connect...

Embodiment 2

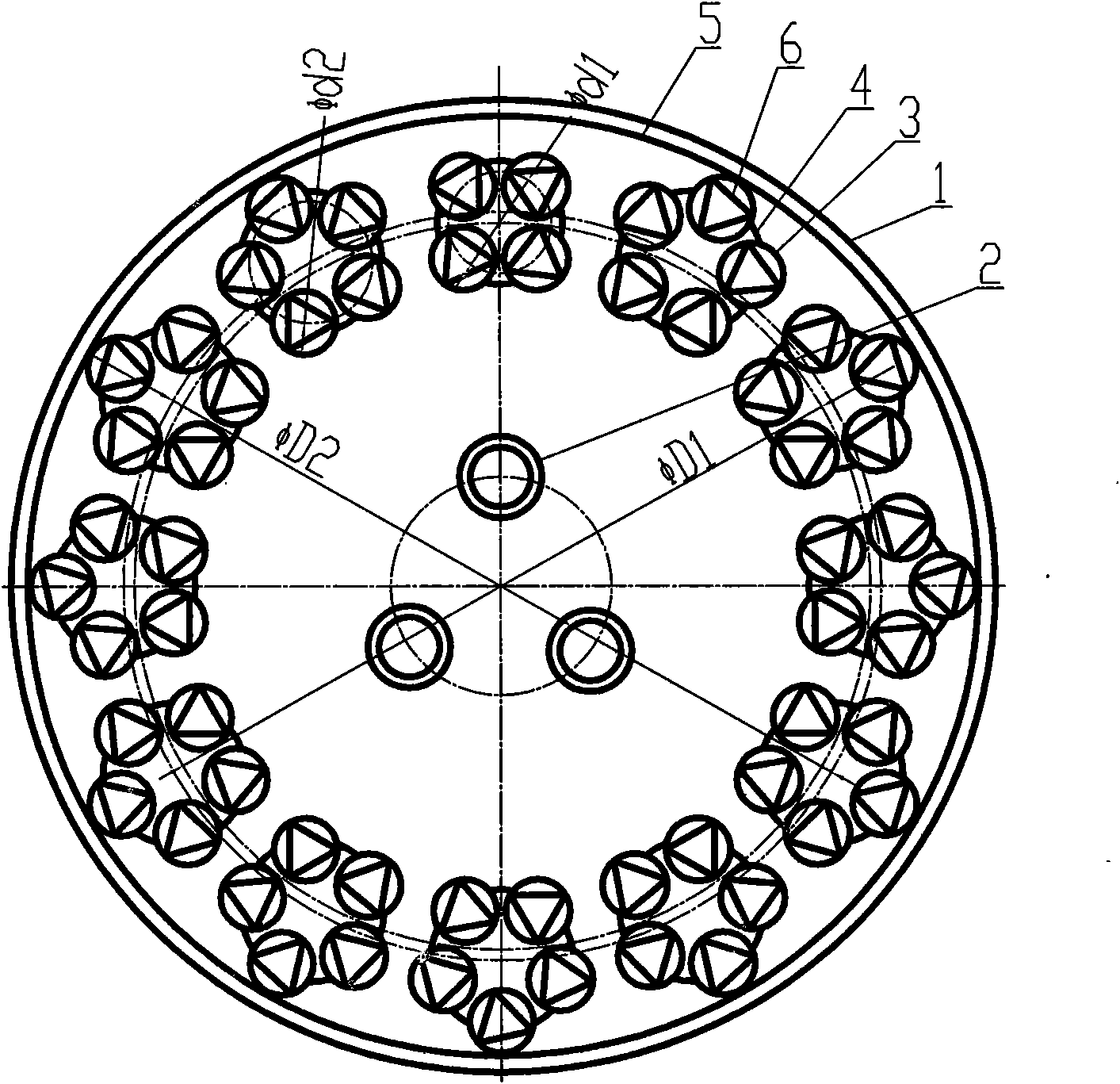

[0038] refer to image 3 , a high-efficiency solar collector tube coating machine, including a vacuum chamber 1, a target 2, a turntable 5 and a clamp 6, the vacuum chamber 1 is a cylindrical cylinder, the cylindrical cylinder has a door, and the target The pole 2 is a cylindrical elongated part that rotates around its axis, the target pole 2 is located in the center of the turntable 5, the turntable 5 is located in the vacuum chamber 1, and the solar heat collector workpiece 3 is clamped on the fixture 6 , the clamp 6 is connected with the driving device through the rotation motion transmission chain, and the turntable 5 is connected with the driving device through the revolution motion transmission chain, and the high-efficiency solar collector tube coating machine also includes 13 turntables 4; 65 clamps 6 Installed on the turntable 4, a fixture 6 is directly installed on the turntable 5; n=5 fixtures are arranged on each turnframe 4; the turnframe 4 is installed on the tur...

Embodiment 3

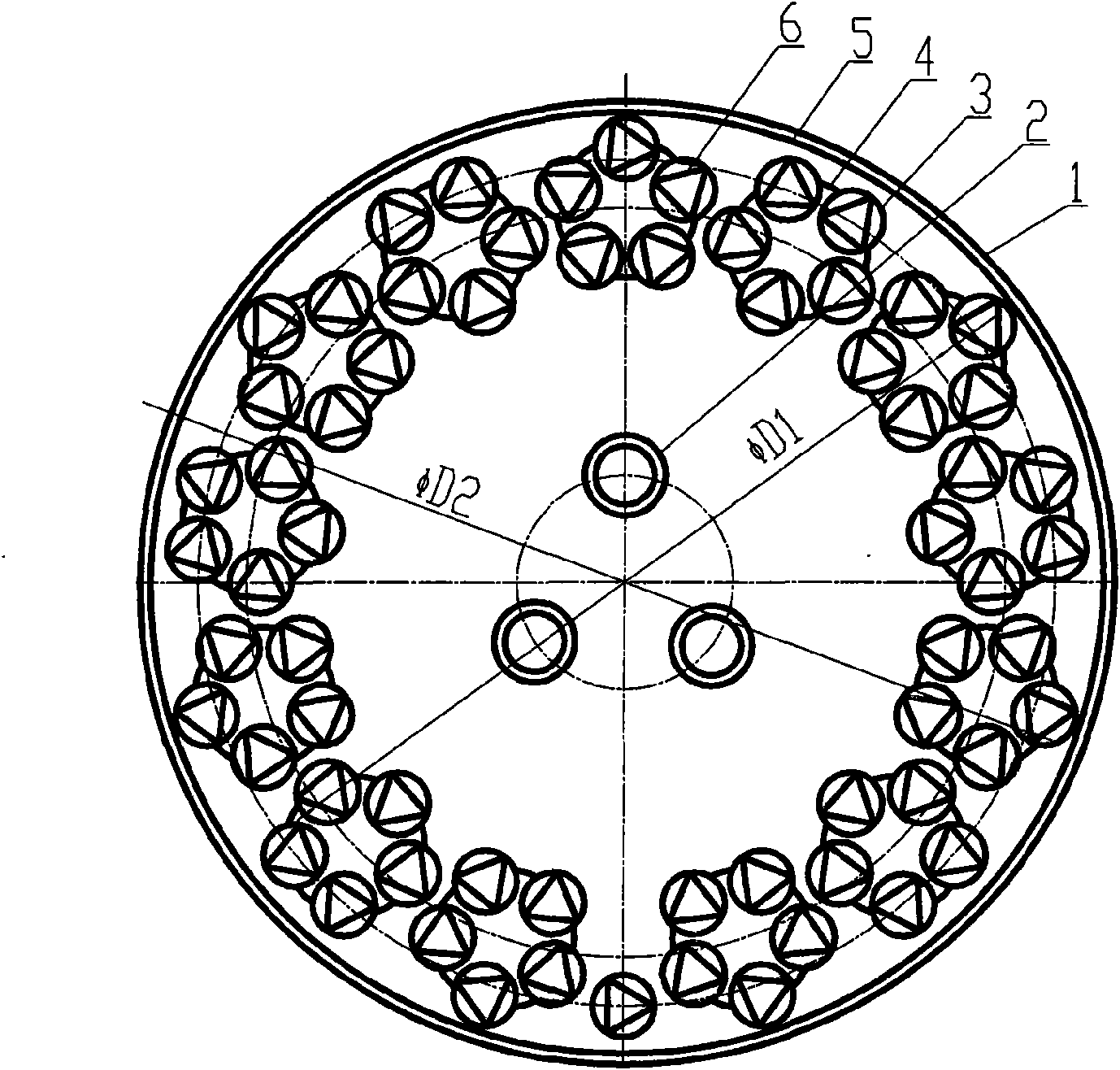

[0044] refer to Figure 4 , a high-efficiency solar collector tube coating machine, including a vacuum chamber 1, a target 2, a turntable 5 and a clamp 6, the vacuum chamber 1 is a cylindrical cylinder, the cylindrical cylinder has a door, and the target The pole 2 is a cylindrical elongated part that rotates around its axis, the target pole 2 is located in the center of the turntable 5, the turntable 5 is located in the vacuum chamber 1, and the solar heat collector workpiece 3 is clamped on the fixture 6 , the clamp 6 is connected with the driving device through the rotation motion transmission chain, and the turntable 5 is connected with the driving device through the revolution motion transmission chain, and the high-efficiency solar collector tube coating machine also includes 12 turntables 4; all the clamps 6 are installed On the turntable 4; there are n=5 clamps 6 on each turnframe 4; the turntable 4 is installed on the turntable 5; the turntable 4 is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com