Method and system for monitoring working condition of injection molding machine during plastic injection molding process

A technology of injection molding machine and working conditions, which is applied in the field of working condition monitoring, can solve the problems that it is difficult to ensure the controllability of monitoring the working conditions of injection molding machines, and achieve the effect of improving controllability and overcoming overfitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

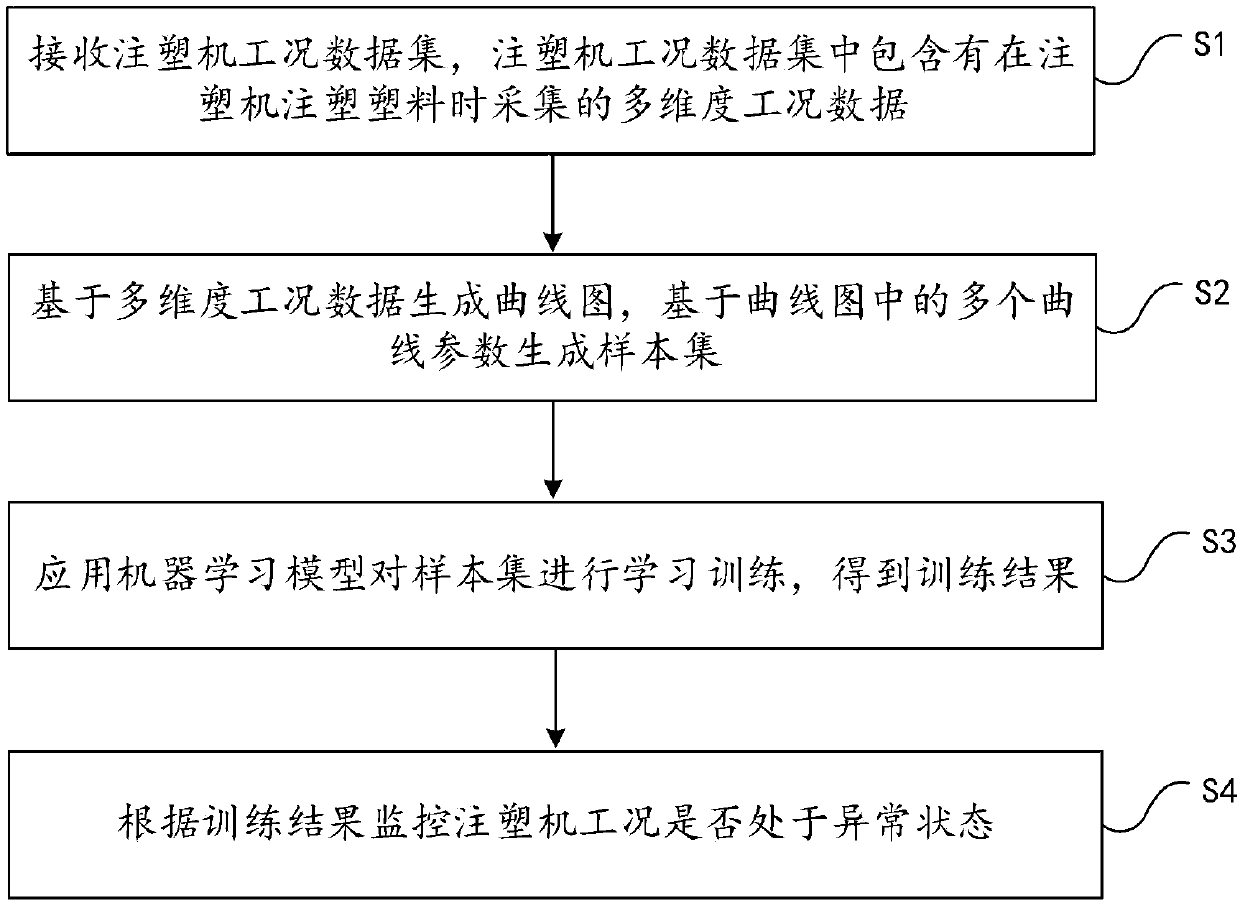

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a method for monitoring the working condition of the injection molding machine in the plastic injection molding process. The method is applied to a server and the plastic is a polymer plastic as an example. The method includes the following steps:

[0024] Step 1, receiving the injection molding machine working condition data set, which contains multi-dimensional working condition data collected when the injection molding machine injects plastic;

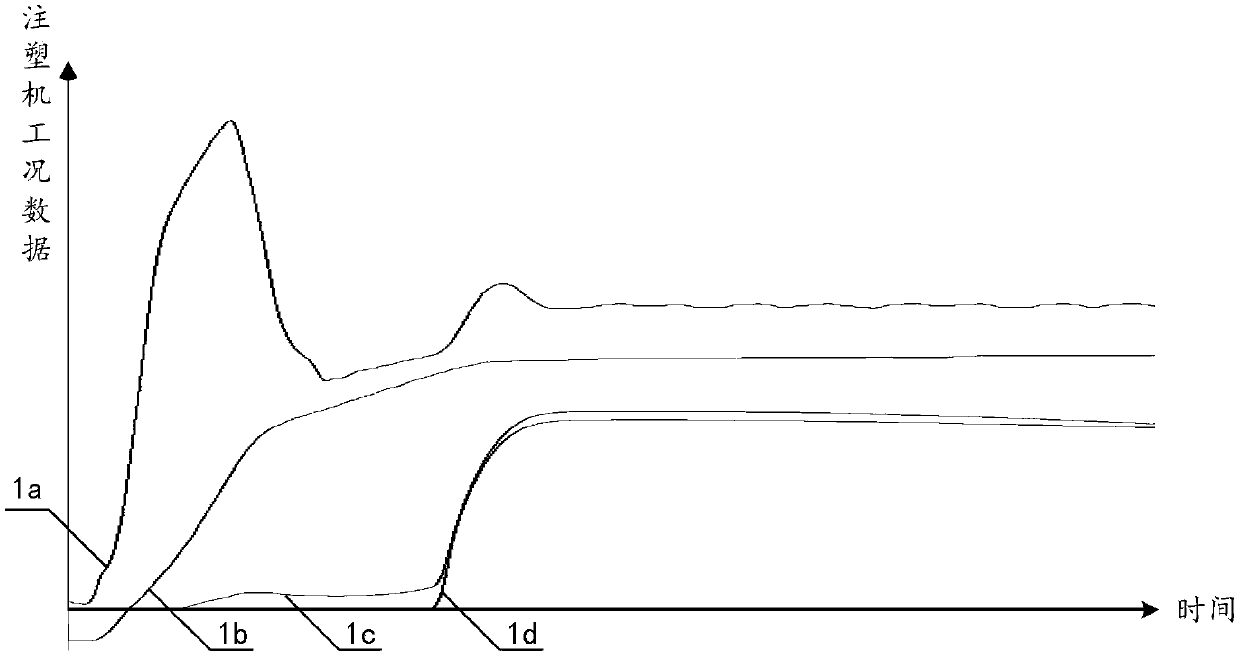

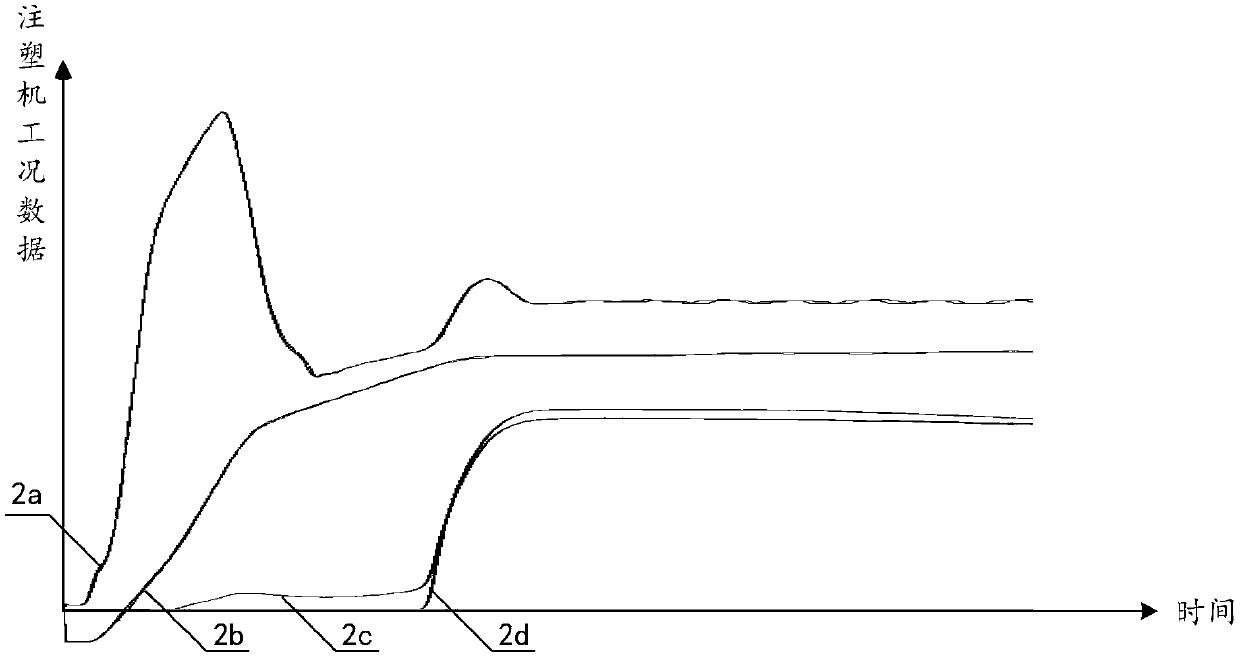

[0025] Step 2, generate a graph based on multi-dimensional working condition data, and generate a sample set based on multiple curve parameters in the graph;

[0026] Step 3, use the machine learning model to learn and train the sample set, and obtain the training result;

[0027] Step 4, monitor whether the working condition of the injection molding machine is abnormal according to the training result.

[0028] The sensor installed on the injection...

Embodiment 2

[0055] Such as Figure 5 As shown, the embodiment of the present invention provides a system for monitoring the working condition of the injection molding machine during the plastic injection molding process. The system includes a data set receiving module, a sample set generating module, a machine training module and an abnormality monitoring module.

[0056] The data set receiving module is used to receive the working condition data set of the injection molding machine. The working condition data set of the injection molding machine contains multi-dimensional working condition data collected when the injection molding machine injects plastic.

[0057] A sample set generation module, configured to generate a graph based on multi-dimensional working condition data, and generate a sample set based on multiple curve parameters in the graph;

[0058] The machine training module is used to use the machine learning model to learn and train the sample set to obtain the training resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com