Flap gate float control method

A technology of a horizontal dock door and a control method, which is applied to dry docks, ships, transportation and packaging, etc., can solve the problems of high risk, large amount of bottom blocking, heavy workload, etc., and meet the requirements of towing, Avoid the effects of underwater work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

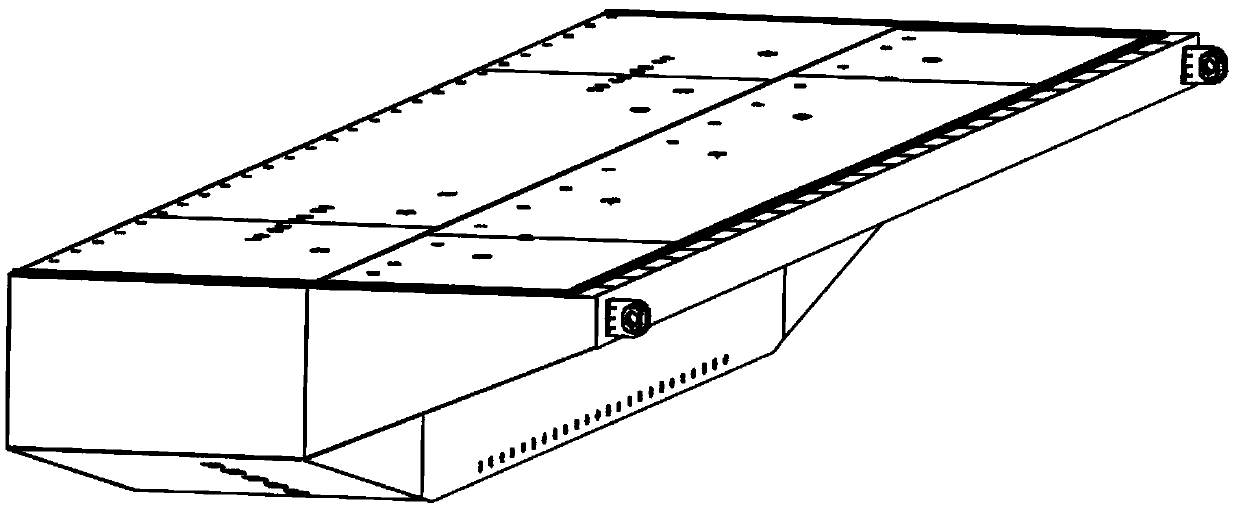

[0022] Such as figure 1 Shown is a three-dimensional view of the lying dock door. It can be seen from the figure that there are openings on the top and bottom of the dock door. Some openings on the top will be the exhaust ports mentioned later, and some openings on the bottom will be the exhaust ports mentioned later. water inlet. In the prior art, generally the opening at the bottom, i.e. the water inlet, is blocked, but not in the present invention.

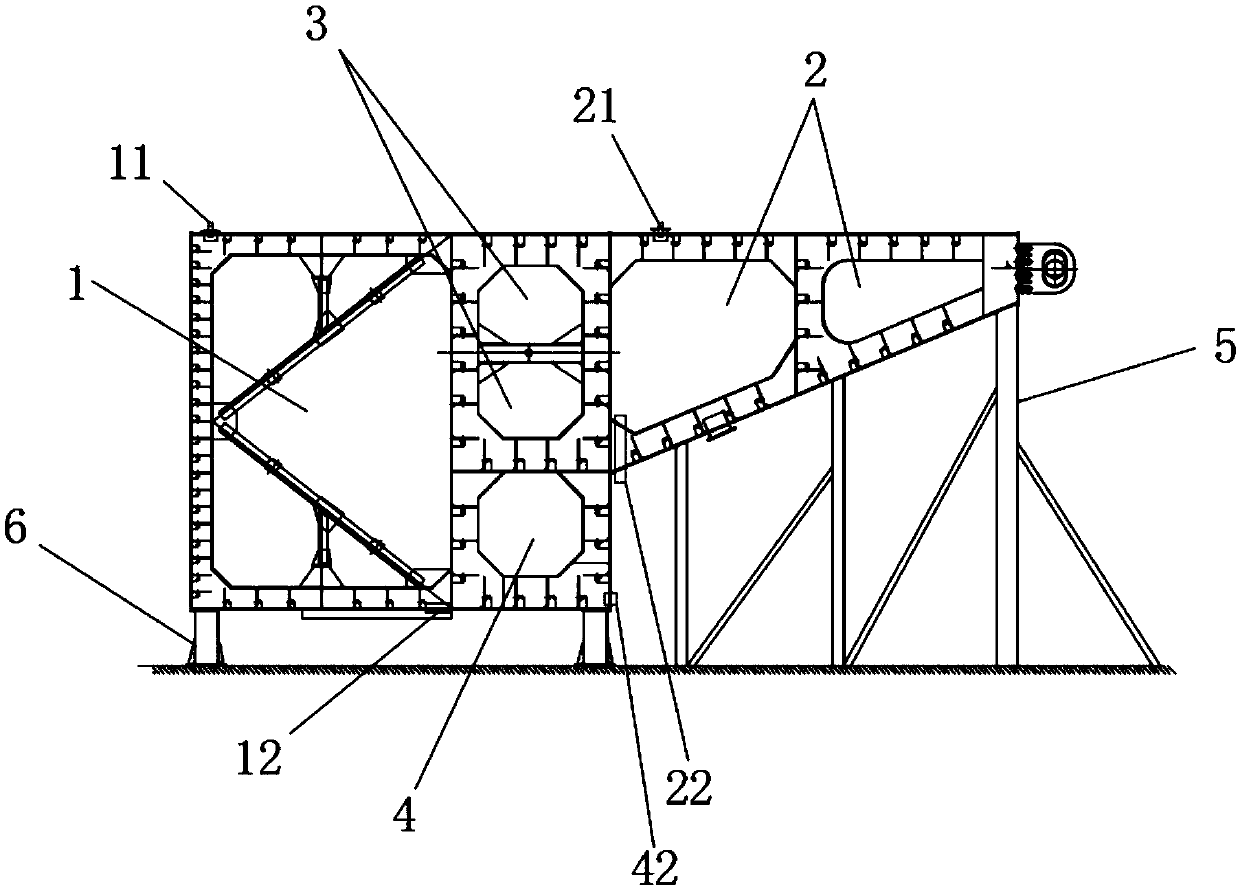

[0023] Such as figure 2 Shown is a cross-sectional view of a lying dock door, figure 2 4 compartments are shown in the figure, respectively tidal compartment 1, fixed floating compartment 3, fixed water compartment 2 and operating compartment 4, which are the basic structures of the recumbent dock doors (they are all in the use process of the dock doors have a role, and will not be ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com