High-pressure synchronous oil seal special for sterm axle of ocean ship

An oil seal, high pressure technology, applied in the direction of engine seal, engine components, mechanical equipment, etc., can solve the problems of high pressure resistance, cracking, expansion and contraction stiffness, etc., to achieve high working reliability, low friction coefficient and long working life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

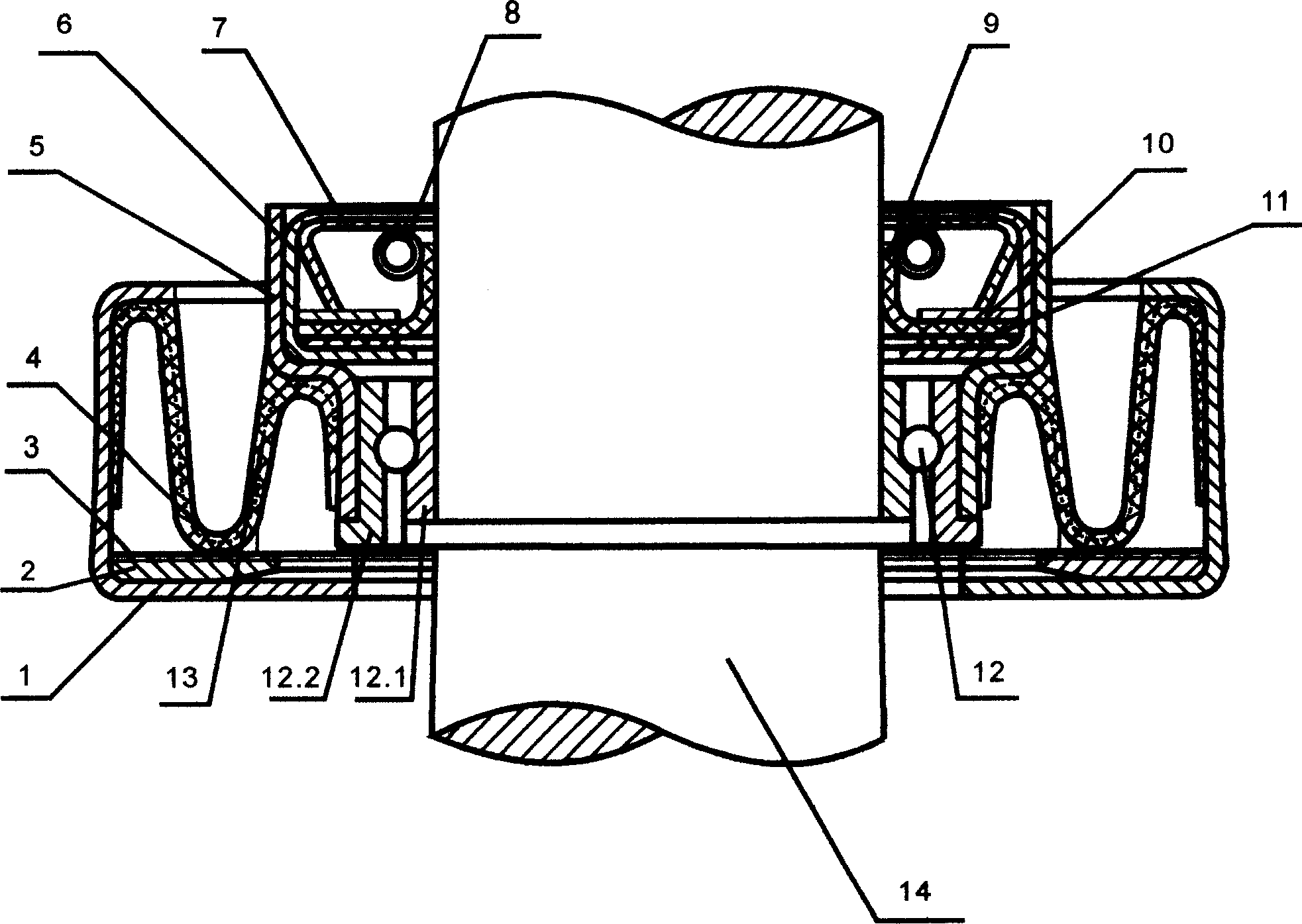

[0027] Such as figure 1 shown. A special high-pressure synchronous oil seal for the stern shaft of a ship, characterized in that the high-pressure synchronous oil seal is composed of three circular parts fixedly connected with a hoop part, an eccentric follower part and an oil pressure receiving part; the fixed connection between the three parts The connection is composed of the outer metal frame 1 on the outer circle, the synchronous frame 5 in the middle, and the oil seal frame 7 on the top, which are both isolation and fixed connection.

[0028] The clamp part is made of filled polytetrafluoroethylene (TF4) material to make the lip 9, under the action of the metal clamp spring 8, the top edge of the lip 9 is close to the rotating shaft 14, and the bottom of the lip 9 The disc is fixedly placed between the compression washer 10 and the rubber washer 11, and the above-mentioned parts are composed of an oil seal outer skeleton fixedly wrapped.

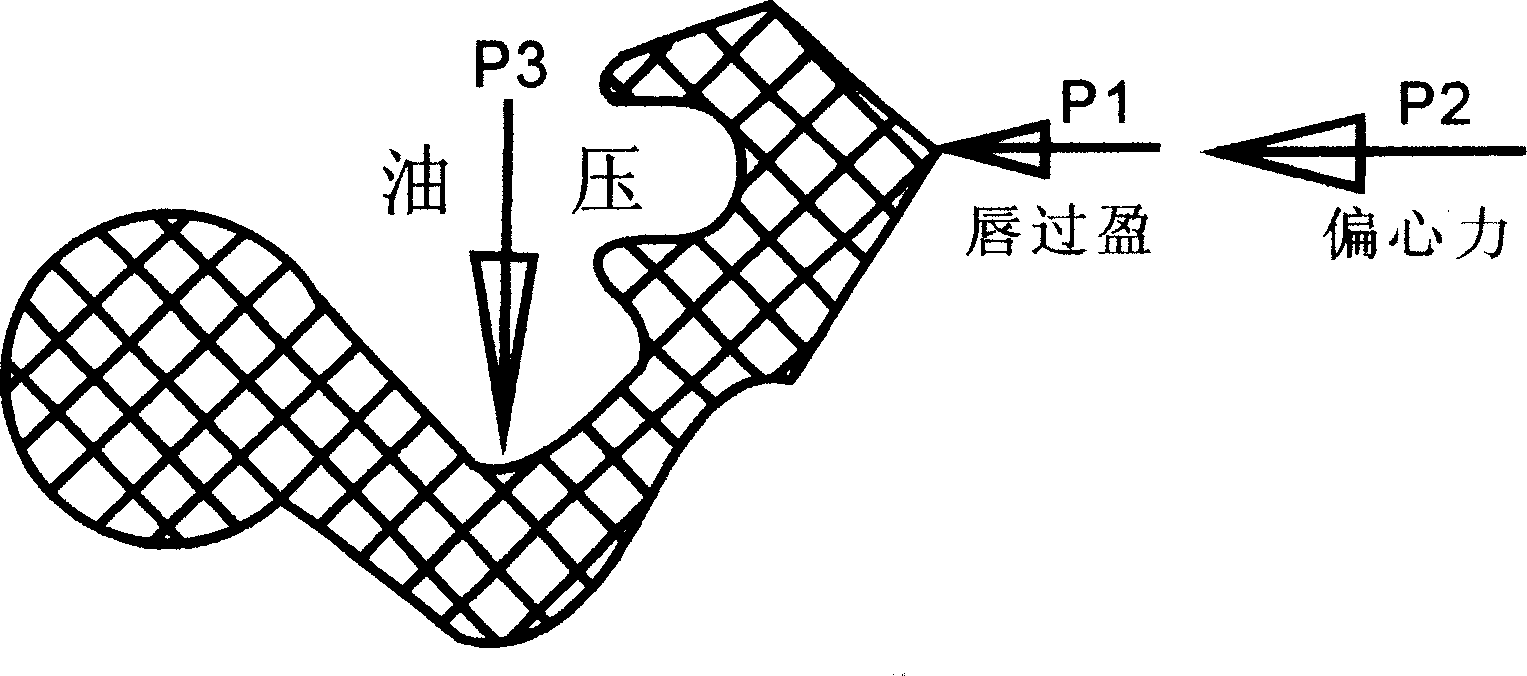

[0029] The tightening force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com