Energy-saving three-phase asynchronous motor

A three-phase asynchronous, electric motor technology, applied in the field of electric motors, can solve the problems of inability to industrialize design and application, slow progress of cast copper rotor motors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

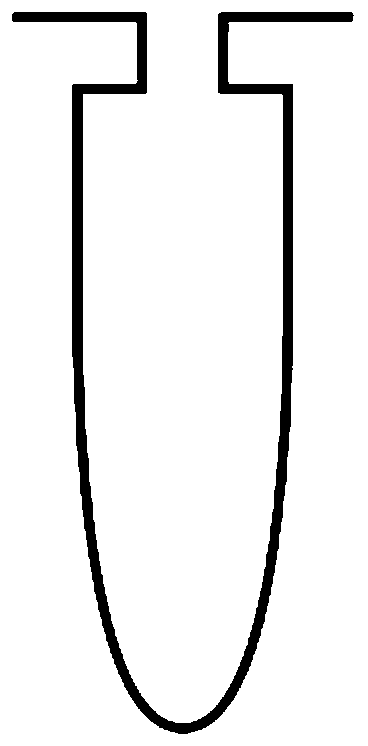

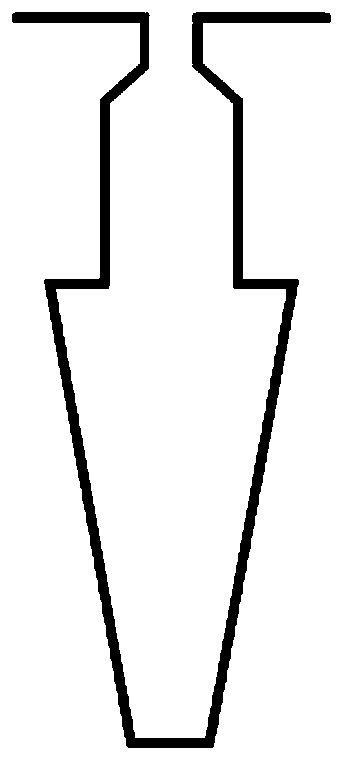

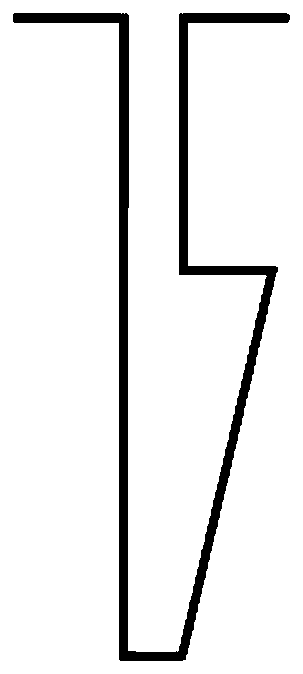

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific embodiments, so as to help understand the content of the present invention.

[0014] 1. Design of cross-sectional area of rotor guide bar

[0015] Cast copper rotor winding three-phase asynchronous motor, design conditions: 2 poles, 380V, 50Hz.

[0016] Design according to three powers of 1.1kw, 4kw, and 5.5kw, and control the cross-sectional area of the copper rotor bar at 60-70% of the cross-sectional area of the aluminum rotor bar with the same power and number of poles to obtain the rotor loss.

[0017] See Table 1 for the loss of rotors with different cross-sectional areas of cast copper and cast aluminum under different power, and see Table 2 for the power

[0018] Table 1: Loss reduction rate of cast copper rotor

[0019]

[0020] Table 2 Cast copper and cast aluminum rotor power values

[0021]

[0022] The actual test of the cast copper rotor motor designed accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com