A kind of composite curing agent based on biomass and sludge co-firing ash and its application

A composite curing agent, biomass ash technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve the problems of fly ash human health hazards, occupation of land space, etc., and achieve high social and economic benefits. Benefit, prevent secondary pollution, reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A heavy metal solidified body prepared from raw materials with the following weight (kg):

[0033] Biomass / sludge co-burning ash 10, P O 42.5 grade ordinary Portland cement 7.2, desulfurized gypsum 0.6, domestic sludge ash / printing and dyeing sludge ash 4.5, under normal temperature conditions 300r / min ball milling and mixing for 40min to collect mixed dry powder Waiting for molding.

[0034] Stir and mix polycarboxylate superplasticizer 0.25 and deionized water 4.8 evenly into the above mixture. Add cationic emulsified pitch PC-2 27.1 into the planetary stirring for 10 minutes, and continue stirring for 10 minutes to obtain a solidified body. The cured body is cured for 7 days at a temperature of 20°C to 30°C and a relative humidity of 80% to complete the heavy metal solidification process of the sludge ash.

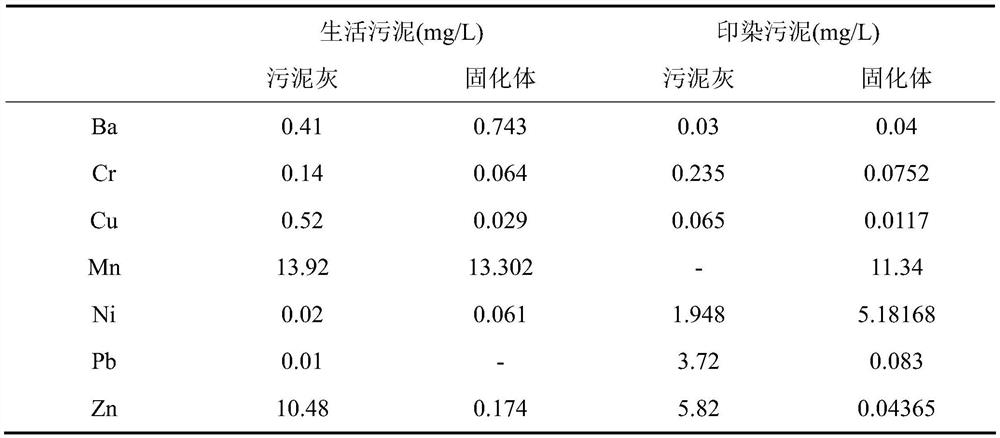

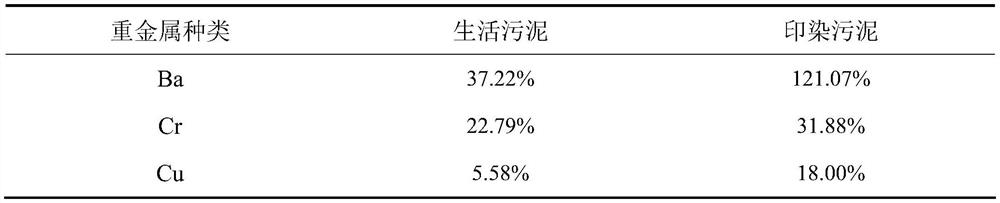

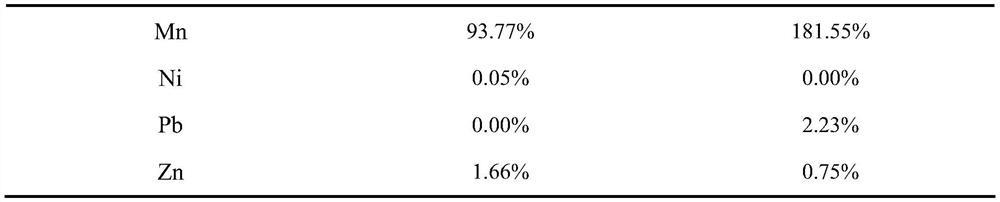

[0035] Evaluate the leaching characteristics of the target heavy metals (Ba, Cr, Cu, Mn, Ni, Zn) in the composite solidified body. The leaching results of the ...

Embodiment 2

[0042] Under the same mixed raw material and method in Example 1, add 21.7 weight (kg) of sand before forming and stirring, and a kind of heavy metal solidified body based on biomass ash with sludge ash as the solidification and stabilization object can be obtained , according to the mechanical properties of the cured body: fluidity (Table 2-1), compressive and flexural strength (Table 2-2), freeze-thaw resistance (Table 2-3).

[0043] Table 2-1 Fluidity of cured body

[0044]

[0045] Table 2-2 Compressive and flexural strength of cured body

[0046]

[0047] Table 2-3 Freeze-thaw strength loss of solidified body

[0048]

[0049] It shows that this cured body has good mechanical properties, can be used in construction, garden roadbed and backfill materials, etc., and has a wide application prospect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com