Magnetic lipase nano-flower catalytic material and preparation method and application thereof

A catalytic material and lipase technology, applied in biochemical equipment and methods, enzymes, hydrolytic enzymes, etc., can solve problems such as difficult separation, reduced stability, and limited industrial application, achieving rapid separation, improved catalytic activity, and eliminating the need for Effect of the high-speed centrifugation step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

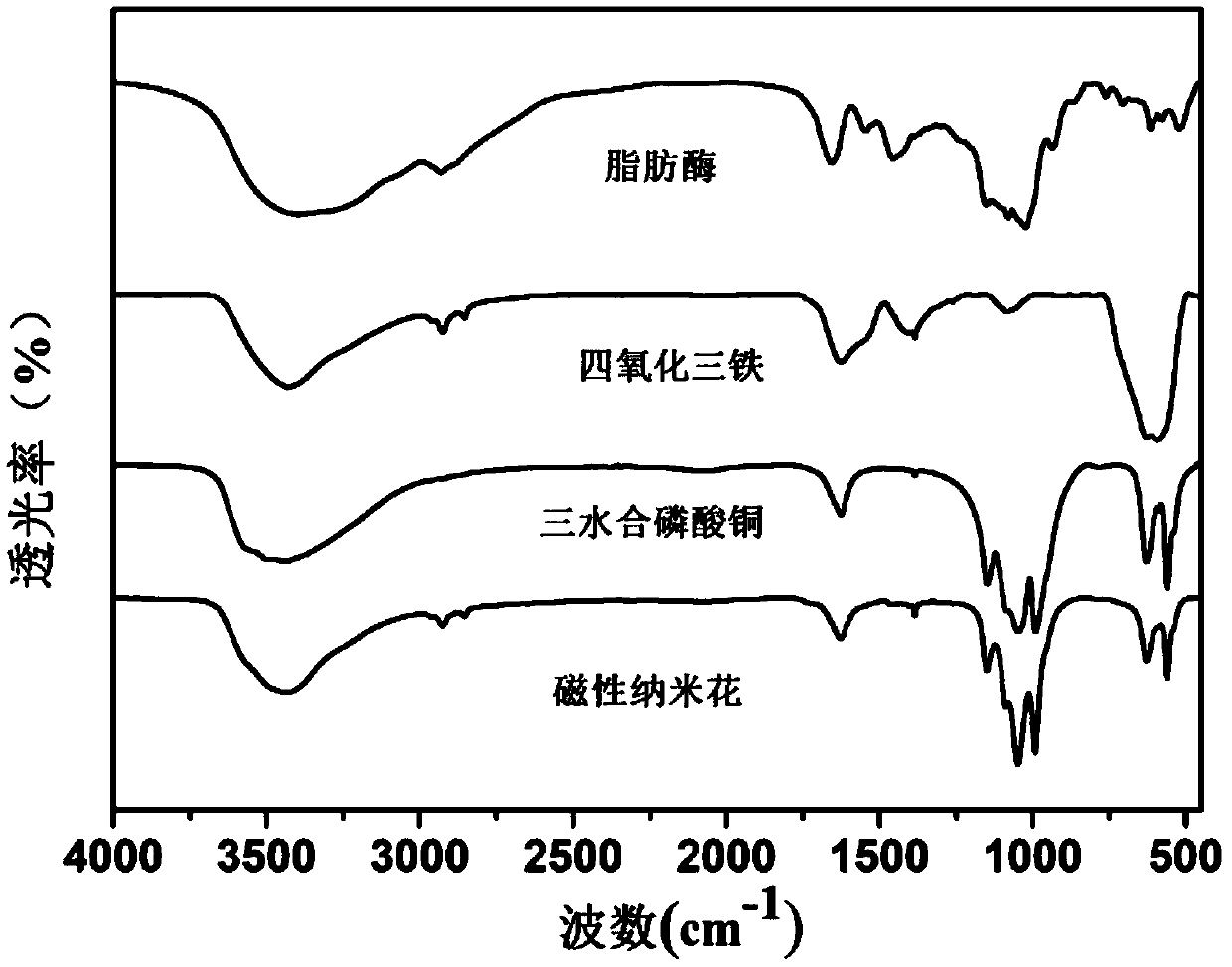

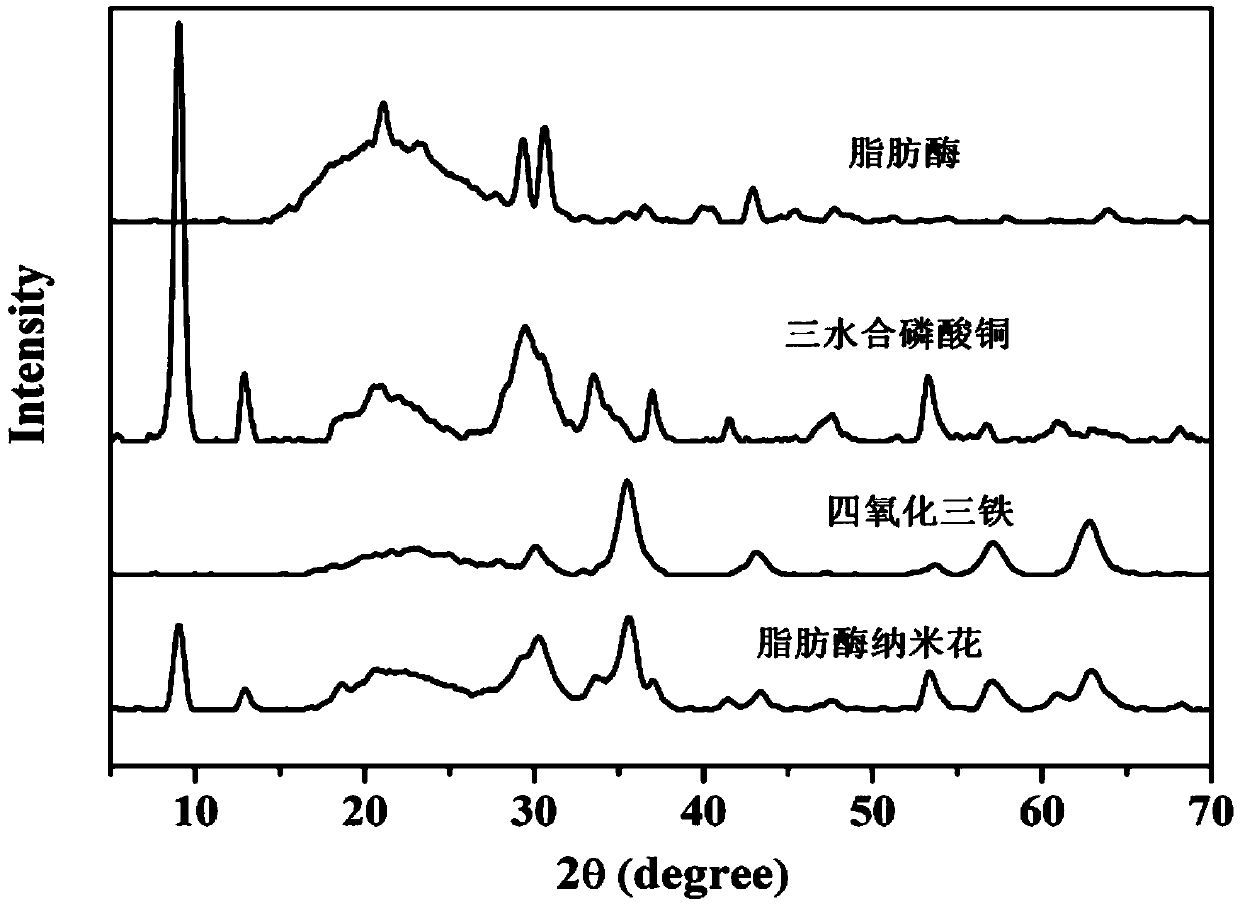

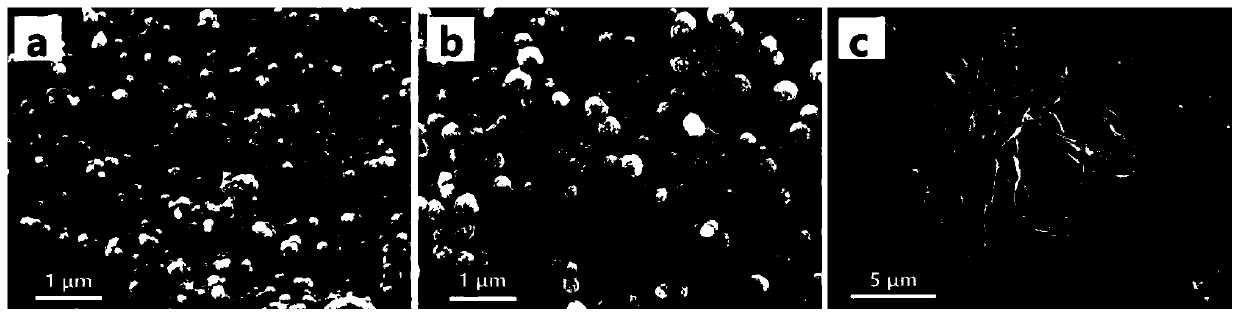

Method used

Image

Examples

Embodiment 1

[0057] (1) Weigh 2.6g FeCl 3 , 1.2g trisodium citrate, ultrasonically dispersed in 80mL ethylene glycol. Add 3.12g of sodium acetate under stirring conditions, stir the mixture at 200r / min for 30min, pour it into the reaction kettle, and keep it warm at 200°C for 20h. Fe was obtained by separation and washing under the condition of an external magnetic field 3 o 4 nanoparticles.

[0058] (2) Weigh 1g Fe 3 o 4 The nanoparticles were poured into 80mL 2M NaOH aqueous solution, stirred continuously for 2h, and the precipitate was collected and washed. Disperse the collected precipitate in 200mL of toluene, add 0.702g of 3-aminopropyltriethoxysilane (APTES) dropwise under stirring conditions, heat to 100°C and reflux for 10h with a water separator, and obtain magnetic properties after silanization modification Silicon-based nanoparticles;

[0059] (3) Prepare 45 mL of lipase solution with a concentration of 0.1 mg / mL with buffer solution, add 5 mg of magnetic silicon-based n...

Embodiment 2

[0067] (1) Weigh 2.6g FeCl 3 , 1.2g trisodium citrate, ultrasonically dispersed in 80mL ethylene glycol. Add 3.12g of sodium acetate under stirring conditions, stir the mixture at 200r / min for 30min, pour it into the reaction kettle, and keep it at 200°C for 20h. Fe was obtained by separation and washing under the condition of an external magnetic field 3 o 4 nanoparticles.

[0068] (2) Weigh 1g Fe3 o 4 The nanoparticles were poured into 80 mL of 2M NaOH aqueous solution, stirred continuously for 2 h, and the precipitate was collected and washed. Disperse the collected precipitate in 200mL of toluene, add 0.702g of 3-aminopropyltriethoxysilane (APTES) dropwise under stirring conditions, heat to 100°C and reflux for 10h with a water separator, and obtain magnetic Silicon-based nanoparticles;

[0069] (3) Prepare a lipase solution with a concentration of 0.25 mg / mL with a buffer solution, take 45 mL of the enzyme solution and add 5 mg of magnetic silicon-based nanoparticle...

Embodiment 3

[0071] (1) Weigh 2.6g FeCl 3 , 1.2g trisodium citrate, ultrasonically dispersed in 80mL ethylene glycol. Add 3.12g of sodium acetate under stirring conditions, stir the mixture at 200r / min for 30min, pour it into the reaction kettle, and keep it at 200°C for 20h. Fe was obtained by separation and washing under the condition of an external magnetic field 3 o 4 nanoparticles.

[0072] (2) Weigh 1g Fe 3 o 4 The nanoparticles were poured into 80mL 2M NaOH aqueous solution, stirred continuously for 2h, and the precipitate was collected and washed. Disperse the collected precipitate in 200mL of toluene, add 0.702g of 3-aminopropyltriethoxysilane (APTES) dropwise under stirring conditions, heat to 100°C and reflux for 10h with a water separator, and obtain magnetic properties after silanization modification Silicon-based nanoparticles;

[0073] (3) Prepare a lipase solution with a concentration of 0.5 mg / mL with a buffer solution, take 45 mL of the enzyme solution and add 5 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap