Molten iron desulphurization method

A technology for desulfurization of molten iron and molten iron, applied in the field of smelting, can solve the problems such as the desulfurization effect needs to be improved, the process is not perfect, the amount of desulfurization powder used is large, and the best desulfurization effect is achieved, and the loss of slag removal is reduced, and the amount of use is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

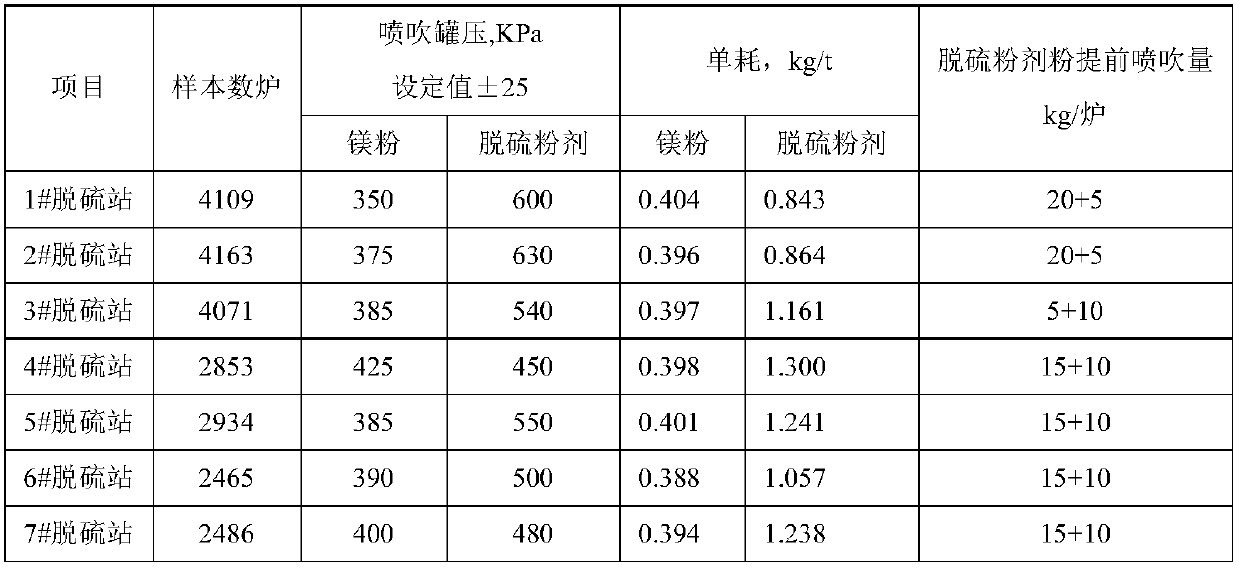

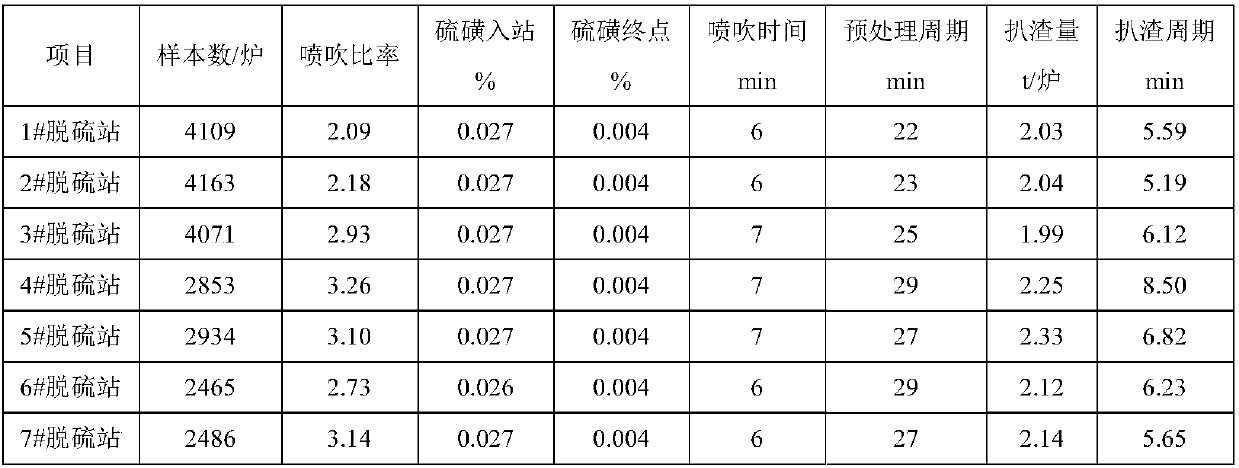

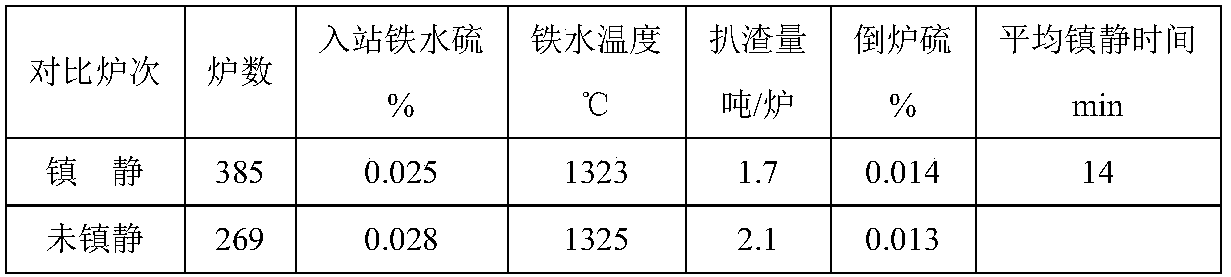

[0010] The present invention will be described in detail below in conjunction with the examples. Seven hot metal desulfurization stations are set up, which are respectively 1#~7# hot metal desulfurization stations; 1#~3# hot metal pretreatment station process flow: the molten iron tank is hoisted to the molten iron tipping car by the crane Up——Dump the tipping car to the injection position—Temperature measurement and sampling——Confirm the amount of powder sprayed—Lower the gun, spray——Elevate and clean the spray gun—Tip over the molten iron tank and remove slag——Reset the molten iron tank ——Temperature measurement and sampling——The end point of sulfur meets the requirements of the regulations, and the dump truck is driven out——The molten iron tank is waiting to be lifted away;

[0011] In the 4#~7# molten iron pretreatment station, the crane lifts the molten iron tank to the molten iron truck—the molten iron truck drives to the pouring station to connect the iron——after connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap