Horizontal circulating fluidized bed boiler with bed material out circulation function

A circulating fluidized bed and external circulation technology, applied in the field of horizontal circulating fluidized bed boilers, can solve the problems of furnace height, high steel consumption, high project cost and initial investment, improve combustion efficiency, ensure stable operation, reduce The effect of slag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation and working process of the present invention will be further described below in conjunction with the drawings.

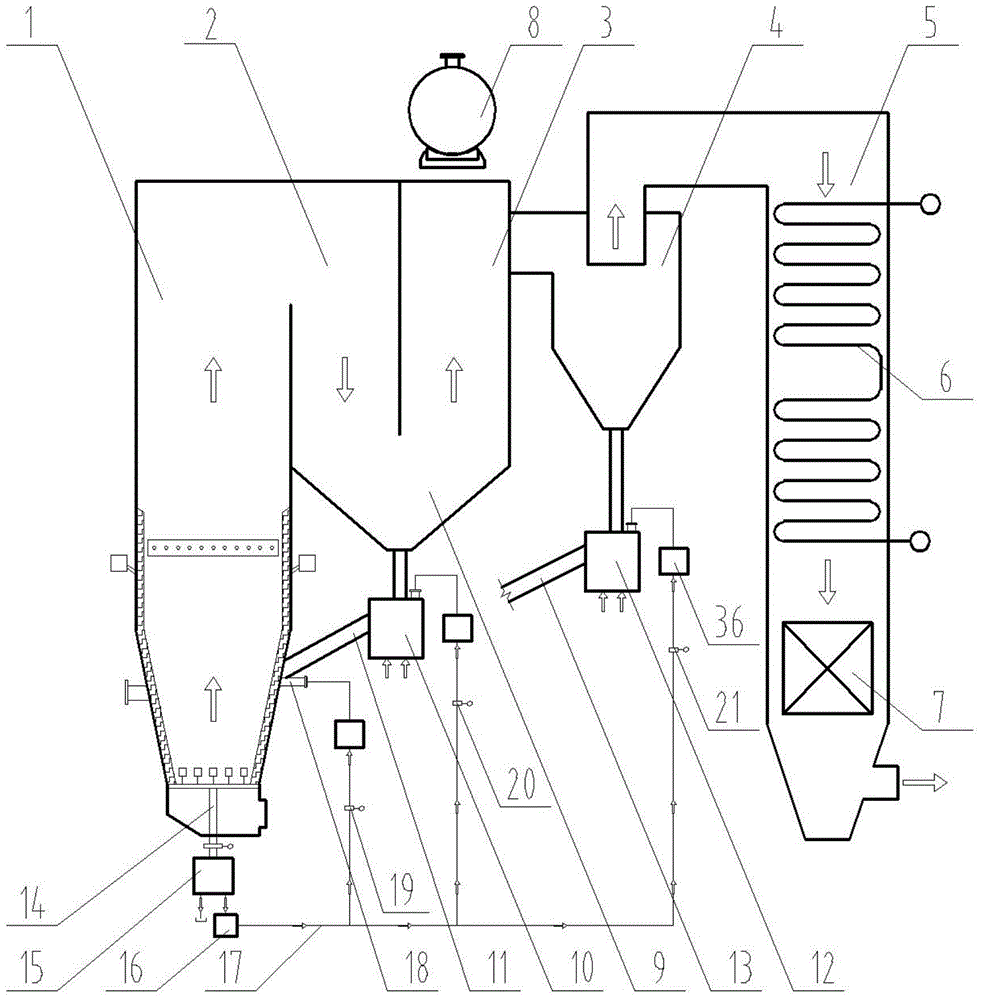

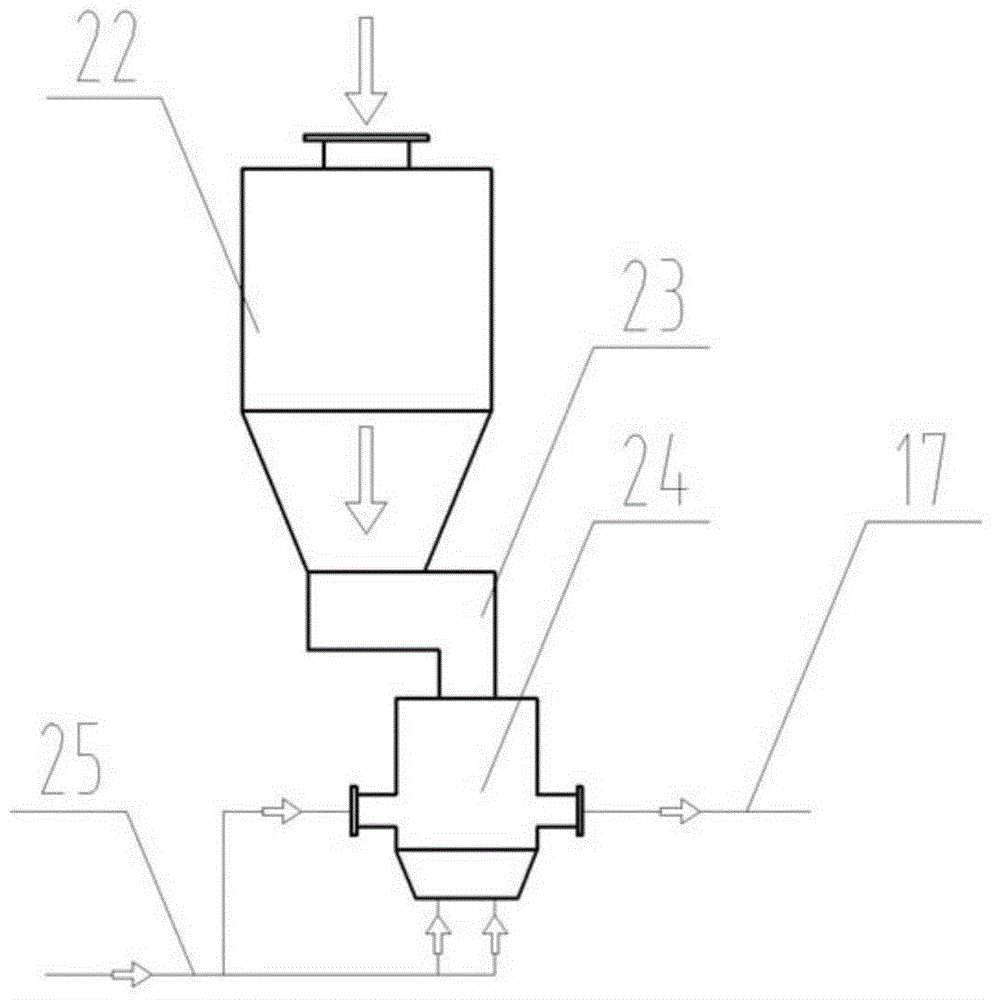

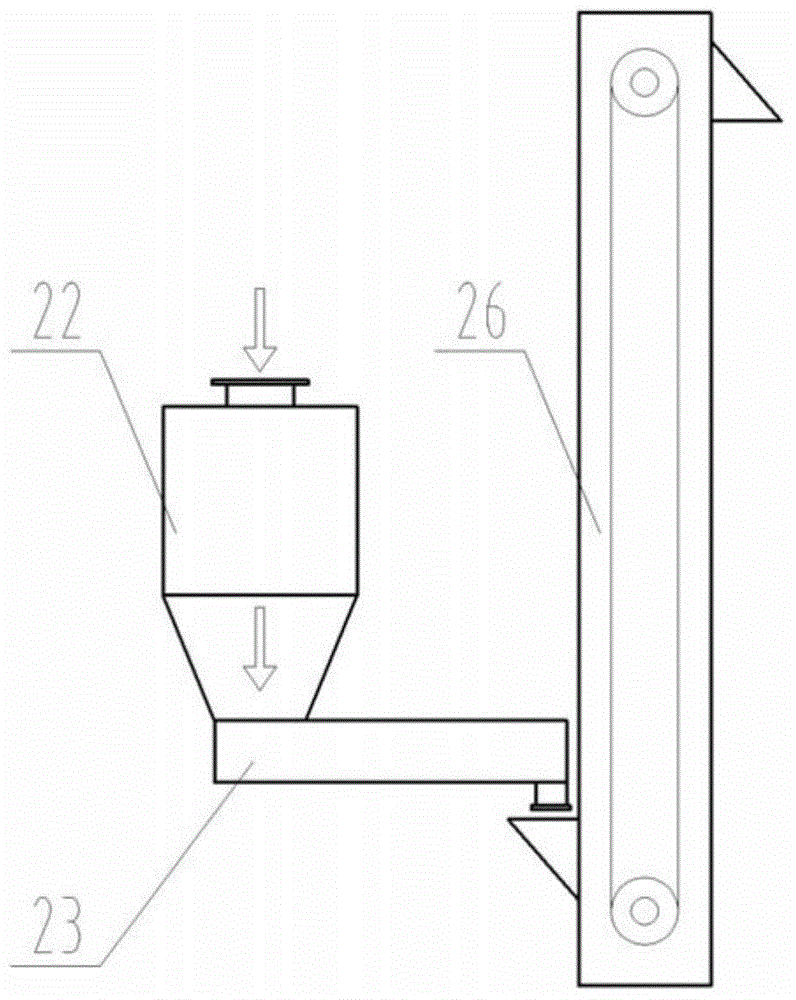

[0018] figure 1 It is a schematic diagram of the horizontal circulating fluidized bed boiler with external circulation of bed material involved in the present invention. It includes a main combustion chamber 1, a secondary combustion chamber 2, a burnout chamber 3, a separator 4, a tail shaft 5, a steam drum 8 and Slag discharge pipe 14; economizer 6 and air preheater 7 are arranged in the tail shaft; ash return hopper 9 is arranged at the lower part of the auxiliary combustion chamber and burnout chamber, and the lower part of the ash return hopper is arranged with a primary return box 10 and a primary return Material pipe 11; the lower part of the separator is arranged with a secondary return box 12 and a secondary return pipe 13; the lower part of the main combustion chamber is arranged with a furnace return port 18; a screening dev...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap