Rotating type faucet valve element

A faucet valve, rotary technology, applied in the direction of sliding valve, valve device, engine components, etc., can solve the problems of shortening the service life of the quick-opening faucet valve core, the multi-inner diameter space of the valve core sleeve, and reducing the wall thickness of the valve core sleeve, etc. Achieve the effect of simple structure, improved structural strength and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

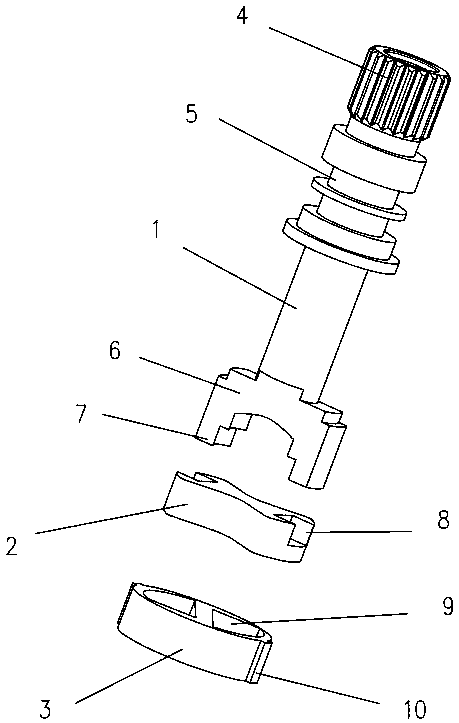

[0010] A rotary faucet spool described in Embodiment 1, such as figure 1 As shown, it includes a rotating screw rod 1, a moving ceramic piece 2 connected with the rotating screw rod and driven to rotate, and a static ceramic piece 3 cooperating with the moving ceramic piece; There are two sealing grooves 5 under the head and used to install the sealing ring, and the adapter 6 located at the bottom of the rotating screw; the inner side of the bottom of the adapter is provided with a boss 7 with a two-level stepped structure, and the moving ceramic plate is provided with an installation card that cooperates with the boss The bayonet 8 that connects, the both sides of static porcelain plate are provided with two water guide holes 9 that realize water channel conduction or sealing when moving ceramic plate rotates, and the plane area of two water guide holes is four times of the plane area of static porcelain plate three thirds.

[0011] In this embodiment, clip strips 10 pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com