Method for improving precision of positioning defects on chip to graphic layer

A graphics layer and accuracy technology, applied in the field of improving the positioning accuracy of defects on the optical sheet to the graphics layer, can solve the problems of inaccurate positioning, the influence of subsequent image formation, and the inability to accurately judge small-sized defects, so as to improve the yield, The effect of reducing the number and speeding up the R&D process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

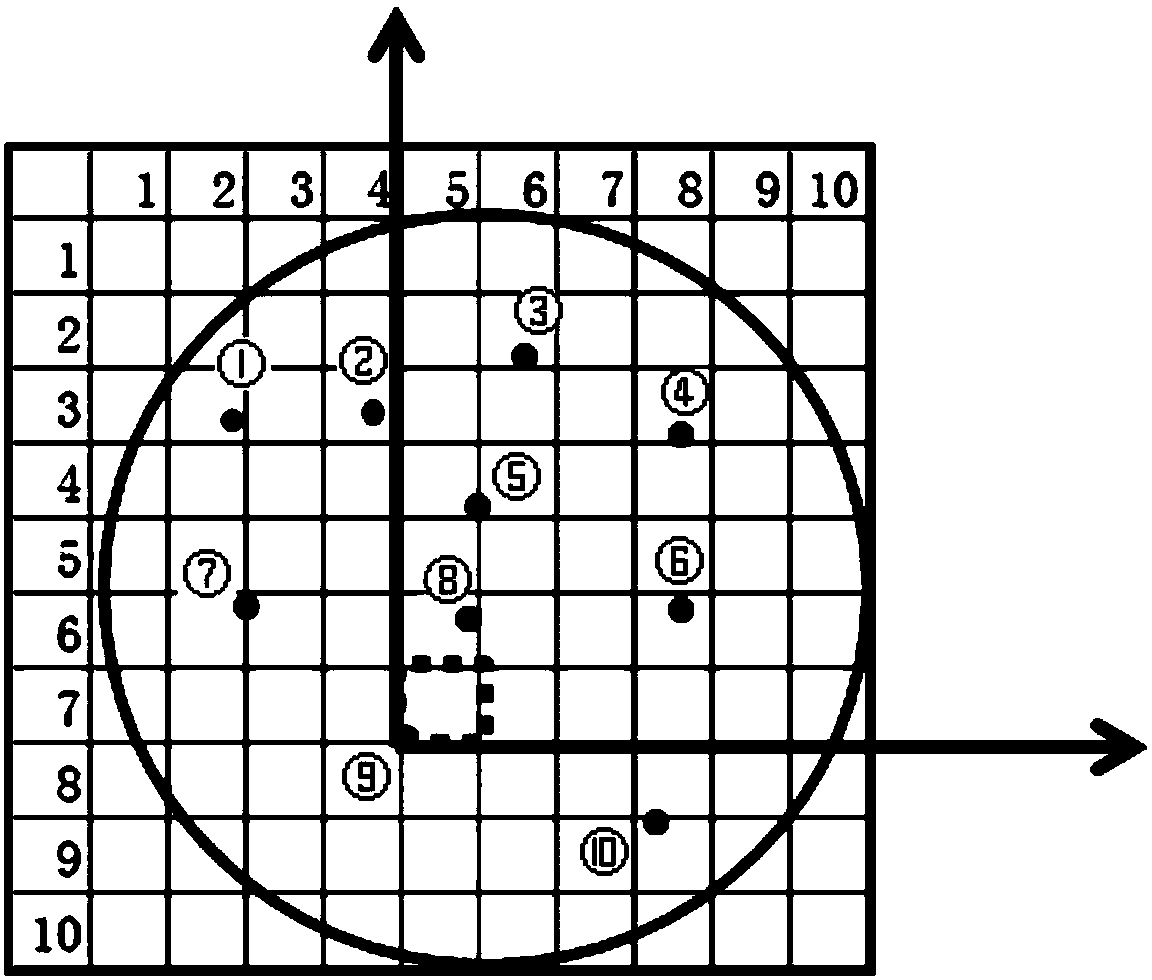

[0010] The method for improving the positioning accuracy of defects on the optical sheet to the graphics layer is based on the principle of adding the smallest repeated complete unit information to the silicon wafer according to the results of electron beam scanning to observe the defects, and then according to the smallest repeated complete unit original complete unit The setting of the origin re-gives each defect a coordinate, so as to improve the positioning of the subsequent silicon wafer with a pattern layer. The specific method is as follows:

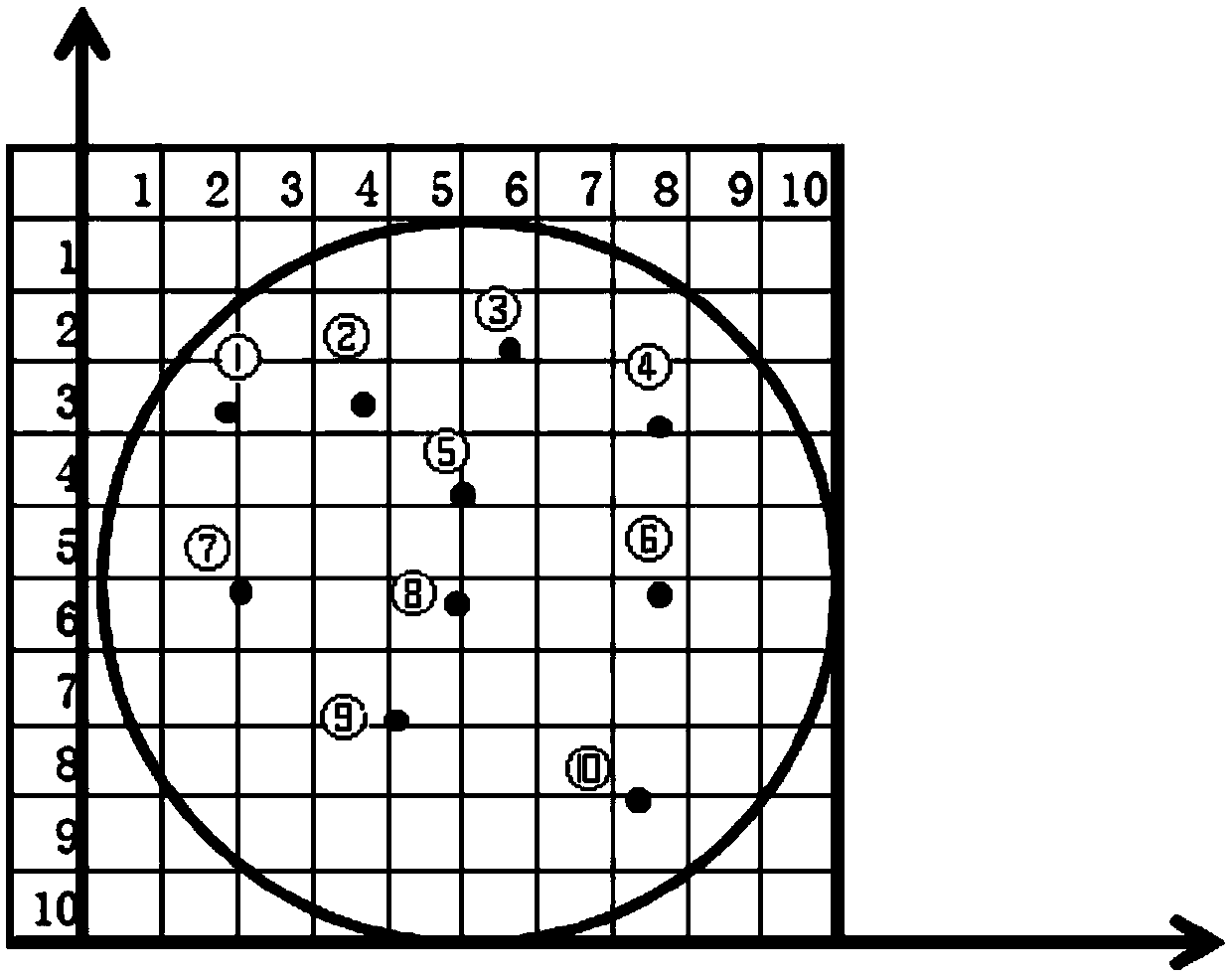

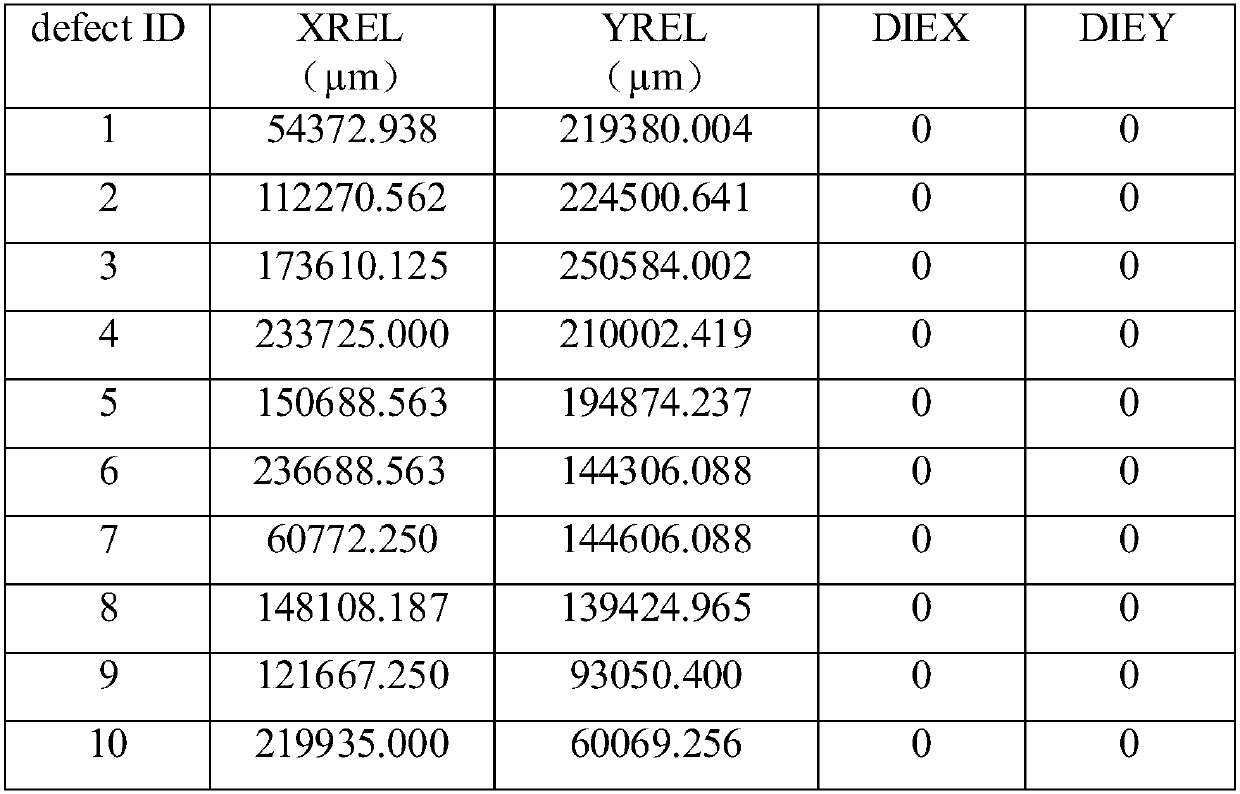

[0011] After the bare wafer is scanned in the bright field or dark field, since there is no pattern on the surface of the silicon wafer, the entire silicon wafer is regarded as a minimum repeated complete unit, and a coordinate position is defined for each defect, such as figure 1 As shown in Table 1, when electron beam scanning is used to observe defects, silicon wafers are aligned according to the notch and crystal edge used for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com