Winding device

A winding device and winding core technology, which is applied in the direction of wire-wound capacitor machines, sustainable manufacturing/processing, electrochemical generators, etc., can solve the problem of quality reduction of winding components and achieve the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

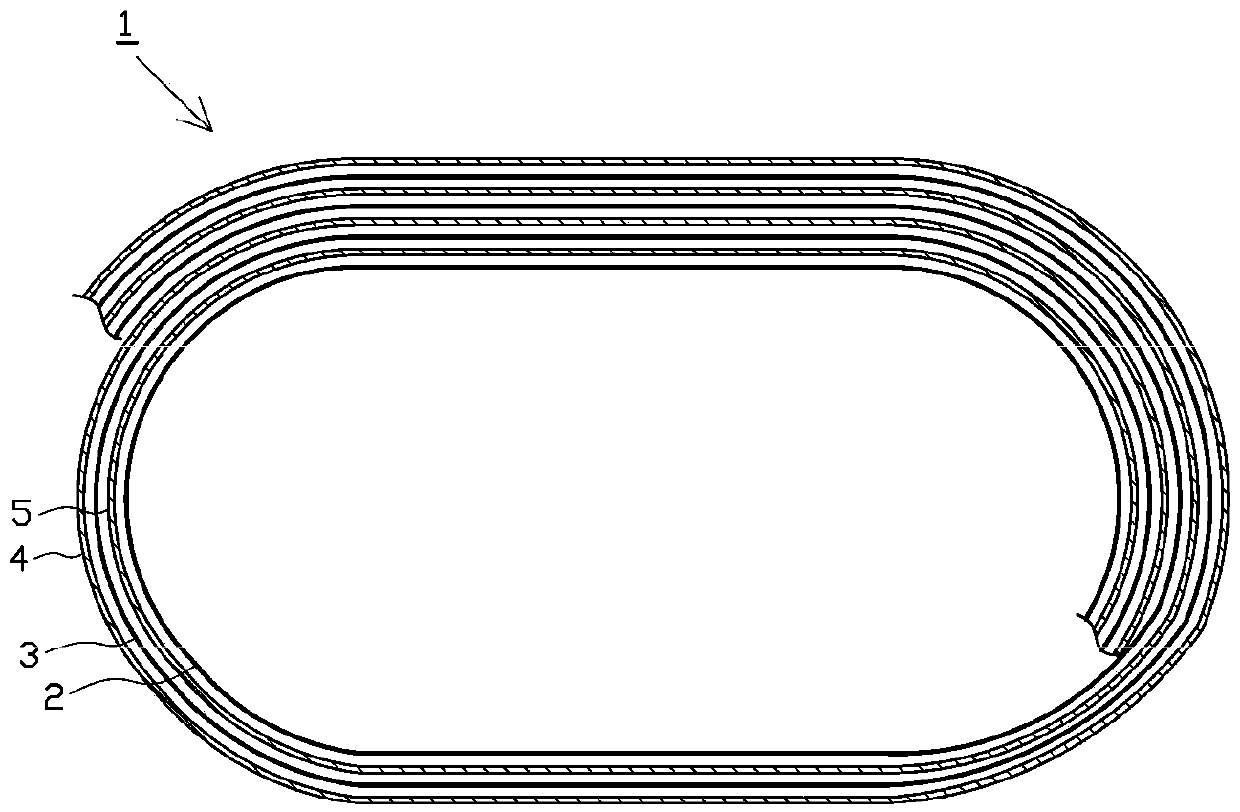

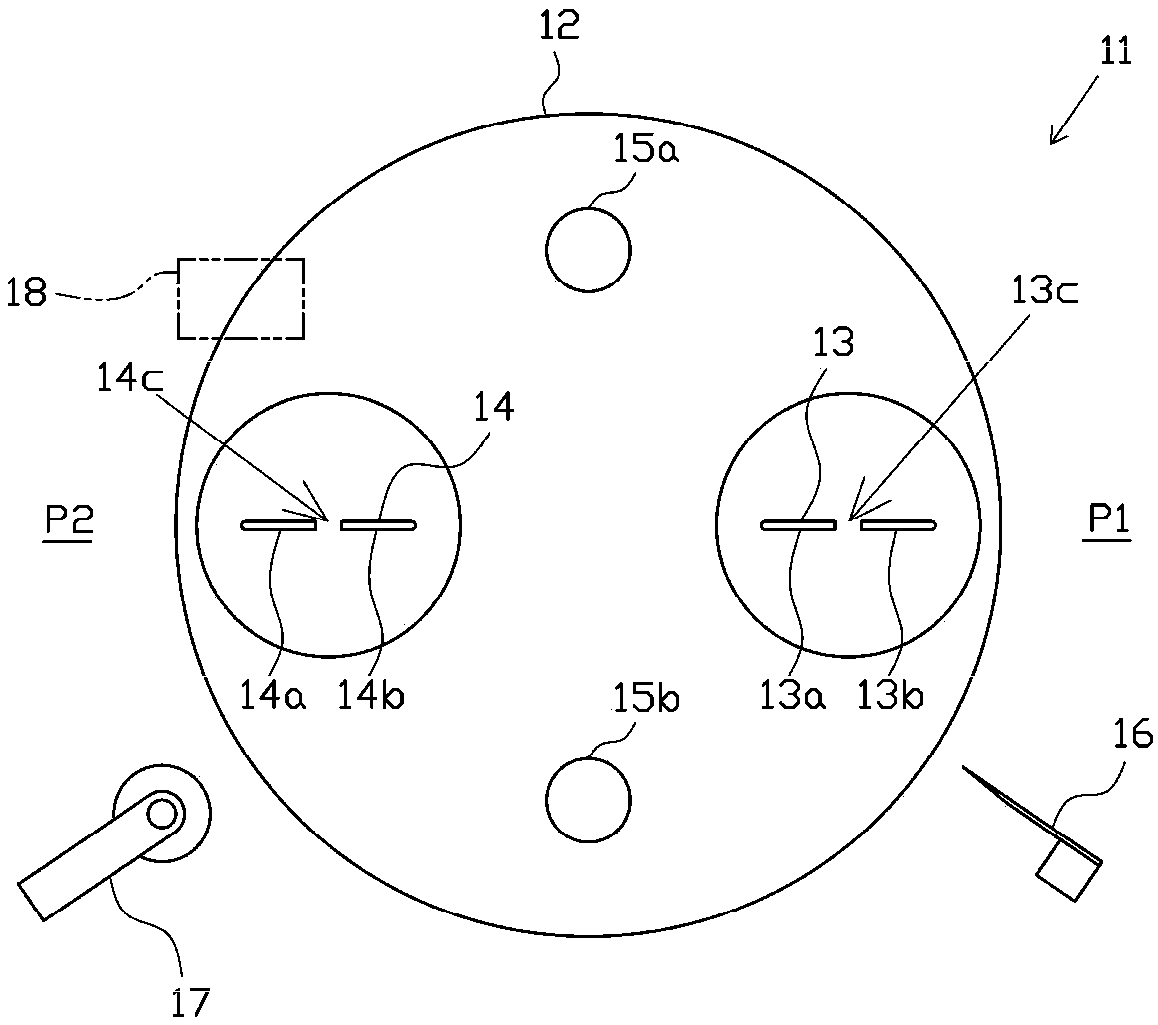

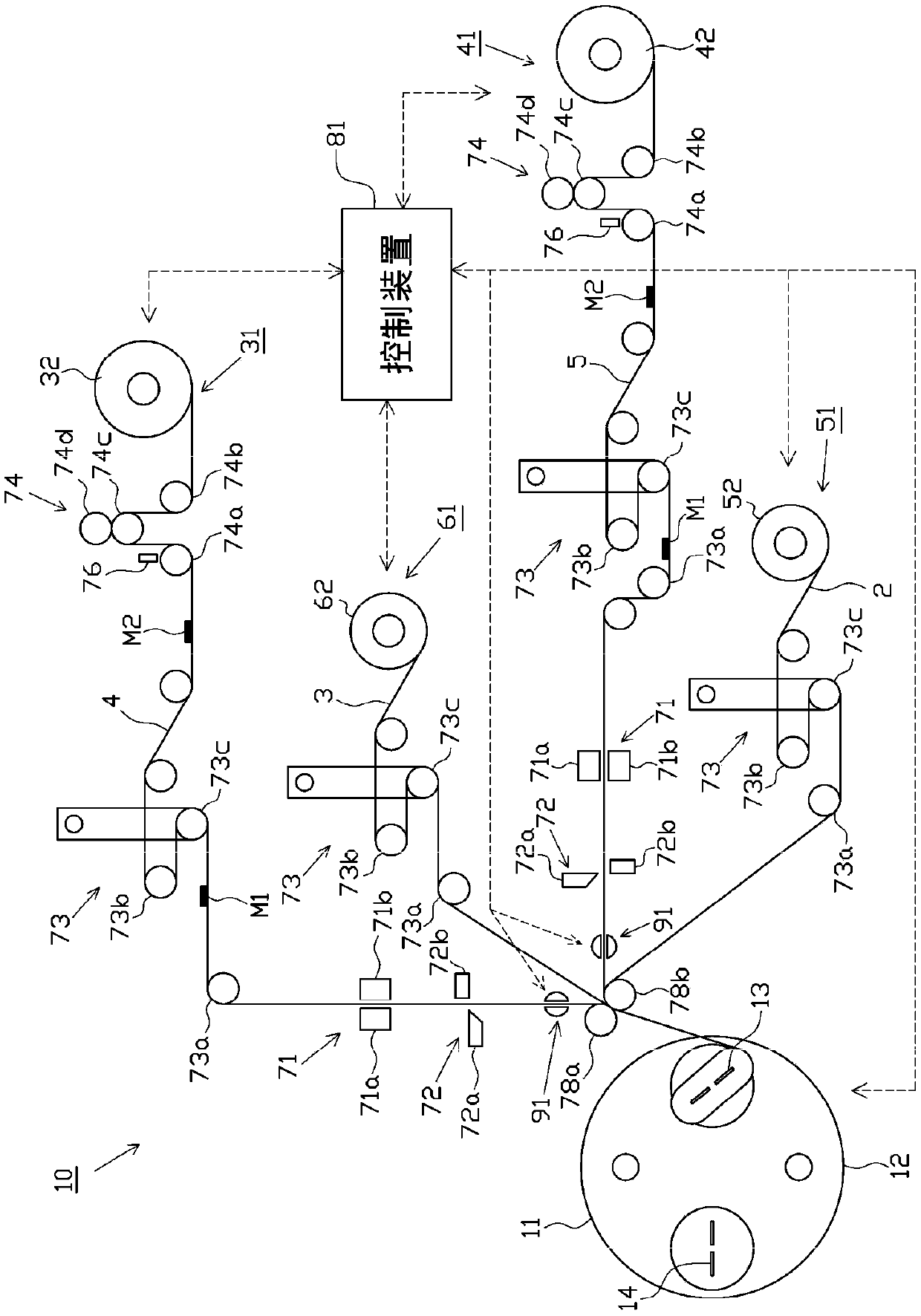

[0071] First, the structure of a lithium ion battery element as a wound element obtained by a winding device will be described.

[0072] picture figure 1 As shown, a lithium-ion battery 1 (hereinafter simply referred to as "battery element 1") is manufactured in such a way that a positive electrode sheet 4 and a negative electrode sheet 5 are overlapped via two separator sheets 2, 3. Status winding. In addition, instead of the two separators 2 and 3, one folded separator may be used. In addition, below, the separator sheets 2 and 3 and the electrode sheets 4 and 5 are referred to as "various sheets 2 to 5" for convenience of description.

[0073] The separators 2 and 3 are strip-shaped with the same width and made of an insulator such as polypropylene (PP) to prevent the electrode sheets 4 and 5 from contacting each other and short-circuiting.

[0074] The electrode sheets 4 and 5 are made of thin metal sheets and have substantially the same width as the separator sheets 2 ...

no. 2 Embodiment approach

[0184] Hereinafter, the second embodiment will be described focusing on the differences from the first embodiment described above.

[0185] In the above-mentioned first embodiment, the path maintaining mechanism is constituted by moving the moving mechanism 96 such as the defective winding core 924 . In contrast to this, in this second embodiment, like Figure 22 , Figure 23 As shown, the route-changing roller 97 provided along the transport route of the positive electrode sheet 4 constitutes the route maintaining mechanism. The path changing roller 97 is installed downstream of the electrode cutter 72 and upstream of the defective winding core 924 . The path changing roller 97 is formed of a freely rotatable roller (pulley). In the following, the path changing roller 97 provided in the positive electrode sheet supply mechanism 31 is described, but the same path changing roller 97 is also provided in the negative electrode sheet supply mechanism 41 .

[0186] The route ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com