Electric wire in-coil winding machine

A technology of wire take-up machine and winding mechanism, which is applied in packaging and other directions, can solve the problems that the equipment cannot realize continuous production, and achieve the effects of simplifying the packaging process, reducing the difficulty of operation, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings.

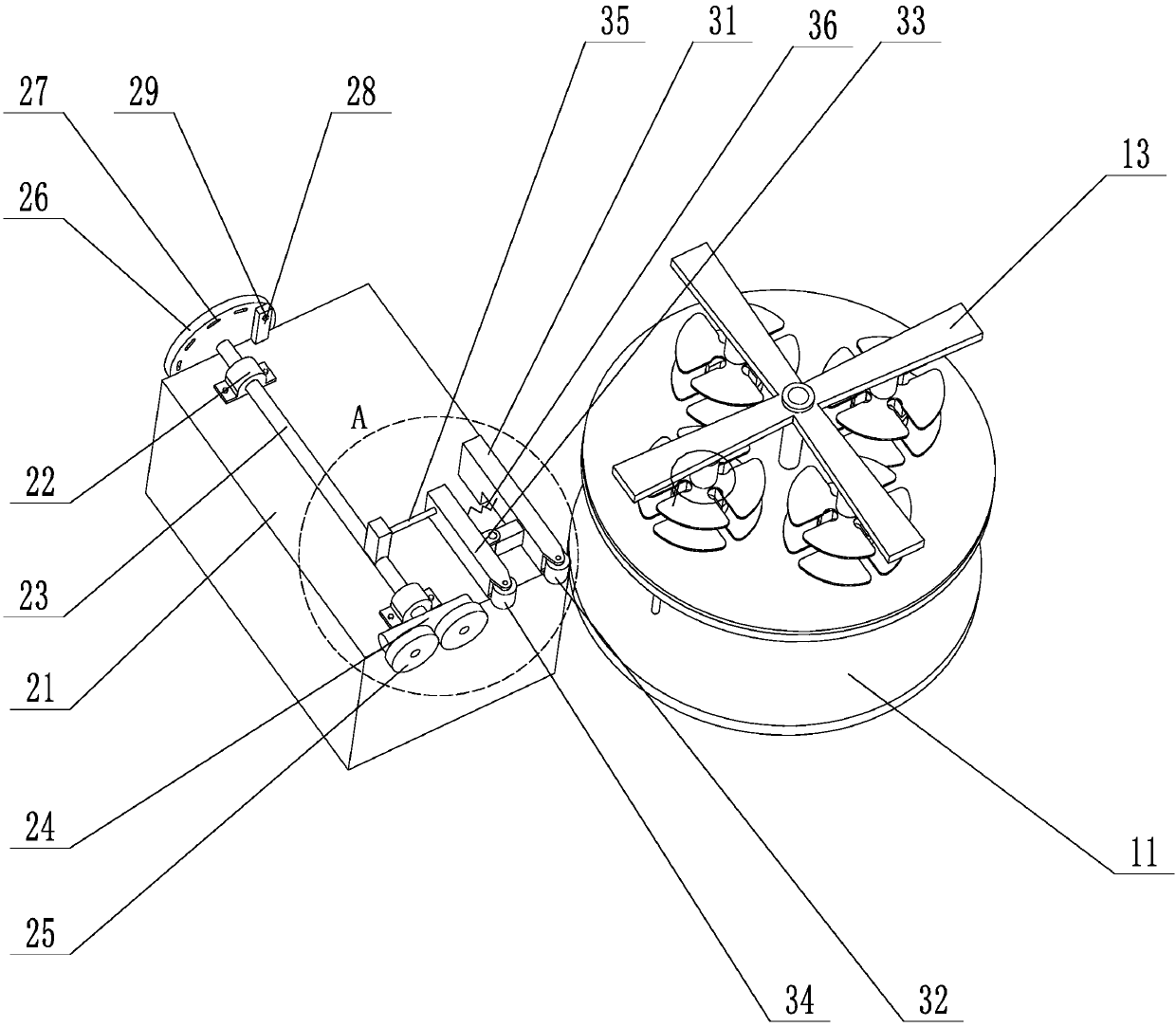

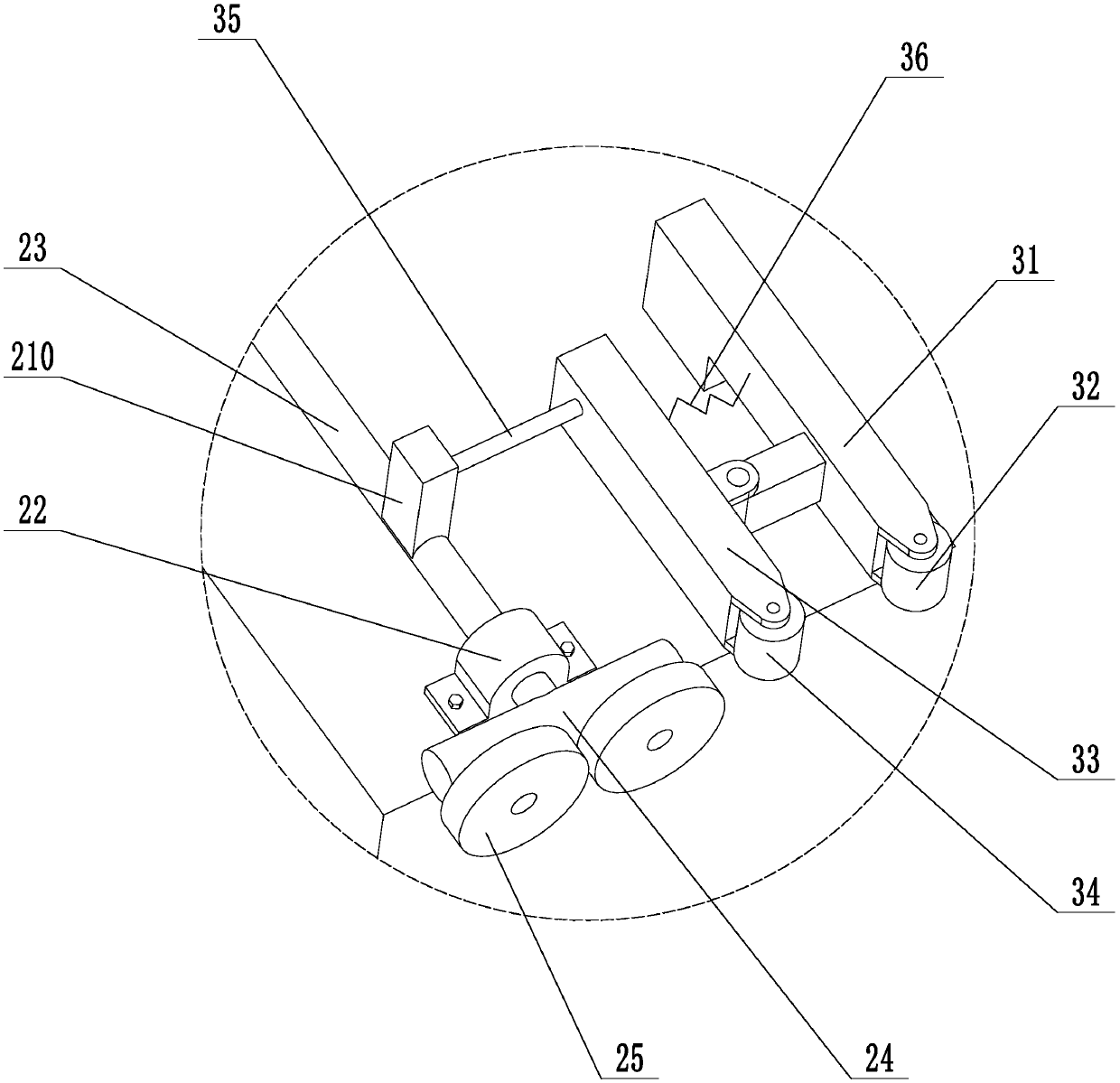

[0055] refer to figure 1 and figure 2 , is a kind of electric wire coil winding take-up machine disclosed by the present invention, which includes two parts: a winding mechanism and a tension adjusting structure.

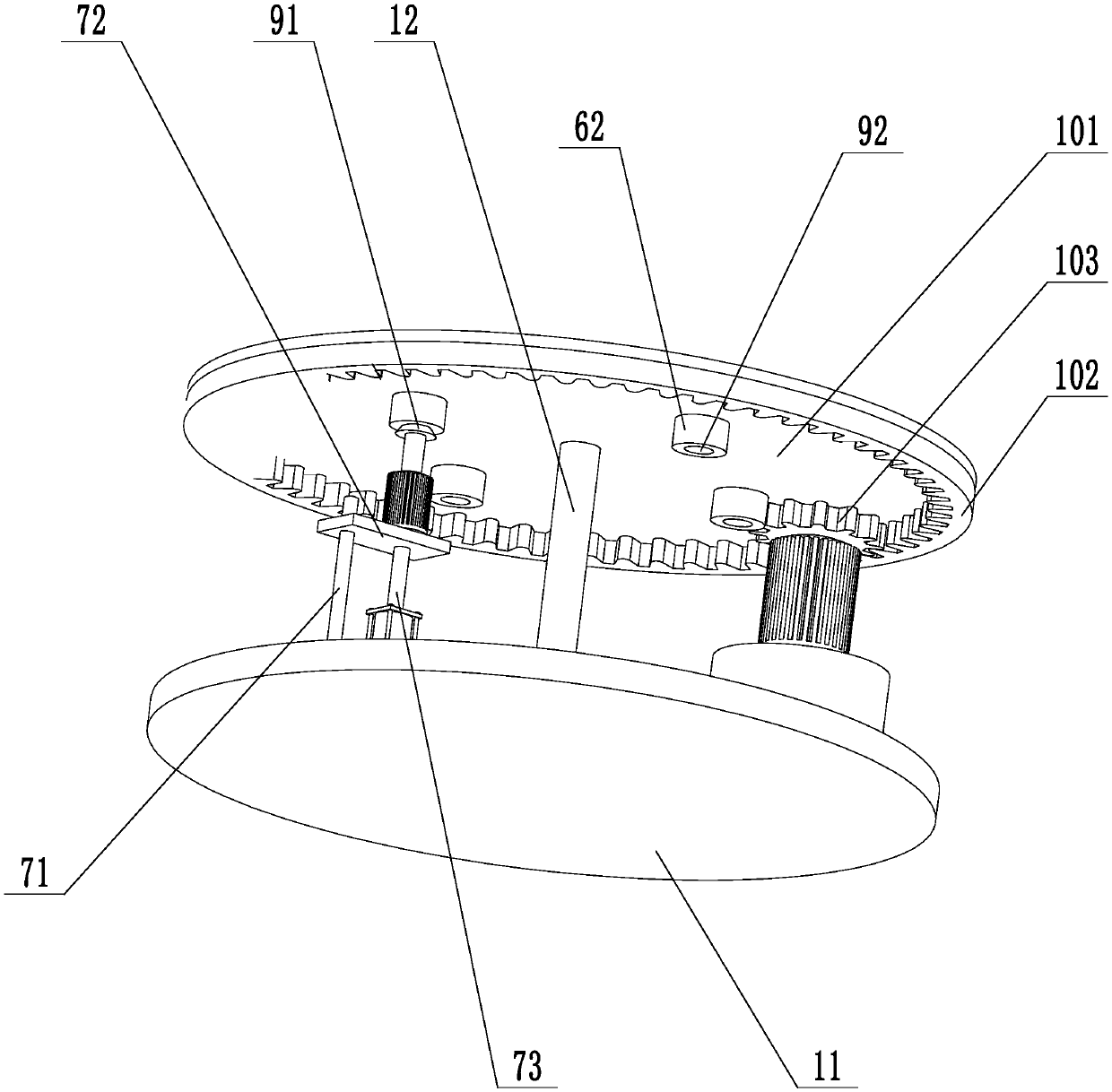

[0056] In the winding mechanism, the base 11 is placed on the floor of the workshop, and the column 12 is vertically fixed at the center of the base 11. The top of the column 12 is rotatably connected with a plurality of cantilevers 13, and the cantilever 13 is in a circular array with the column 12 as the center. Adjacent cantilever arms 13 are fixedly connected, that is, when one of the cantilever arms 13 rotates, the other cantilever arms 13 will also rotate accordingly.

[0057] The tension adjustment structure includes two parts: fixed adjustment and dynamic adjustment.

[0058] In the fixed adjustment part, the tension adjustment workbenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com