Layered water-intake independent intake tower structure for high water head power station

A layered water intake, independent technology, used in hydropower stations, hydroelectric power generation, water conservancy projects, etc., can solve the problem that the accident maintenance gate cannot be remotely controlled, and the water inlet tower of a large-flow power station cannot be used for layered water intake, and the trash rack passes through. The problems such as the small area of the grille can be achieved to achieve the effect of facilitating remote automatic control, convenient opening and closing operation, and increasing the area of the trash grille.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

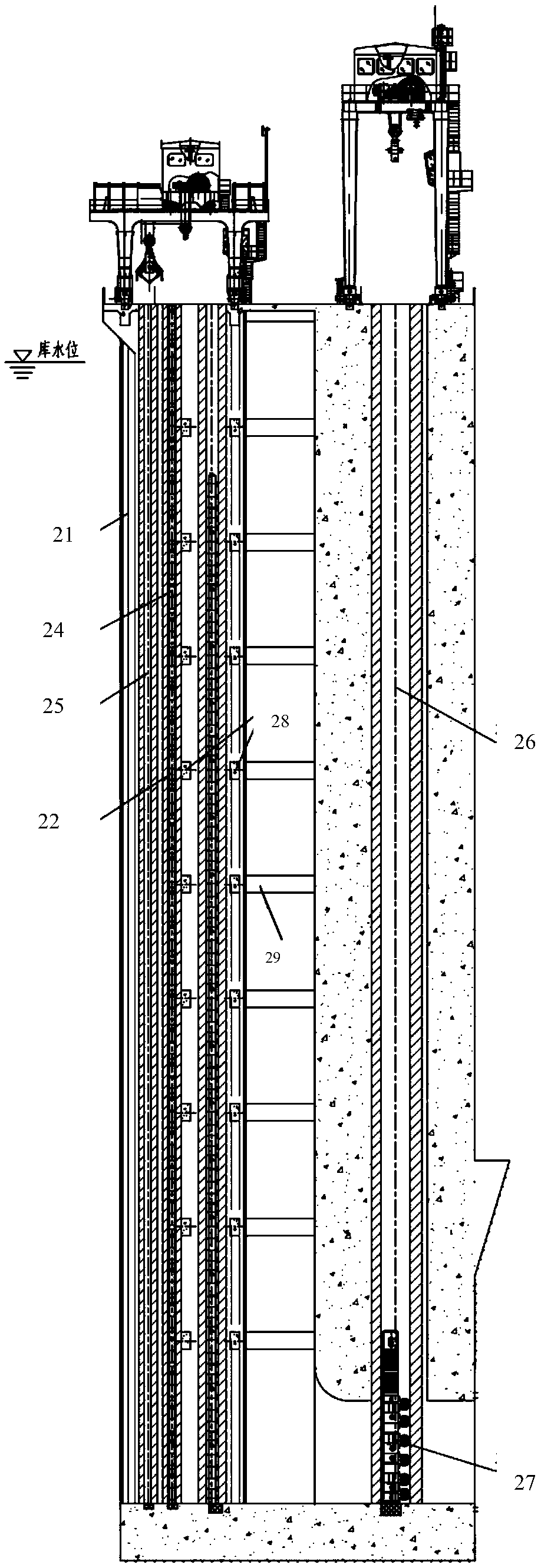

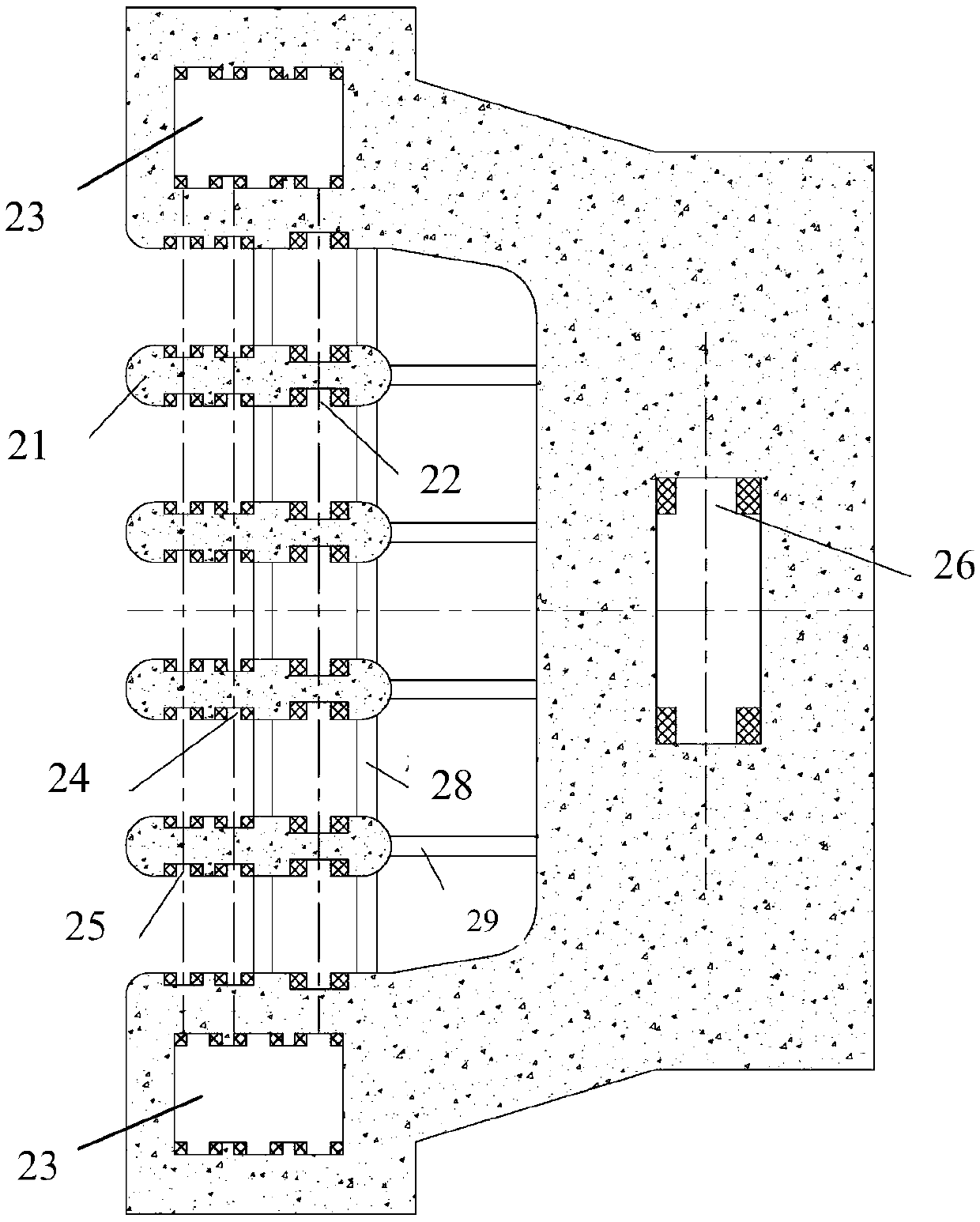

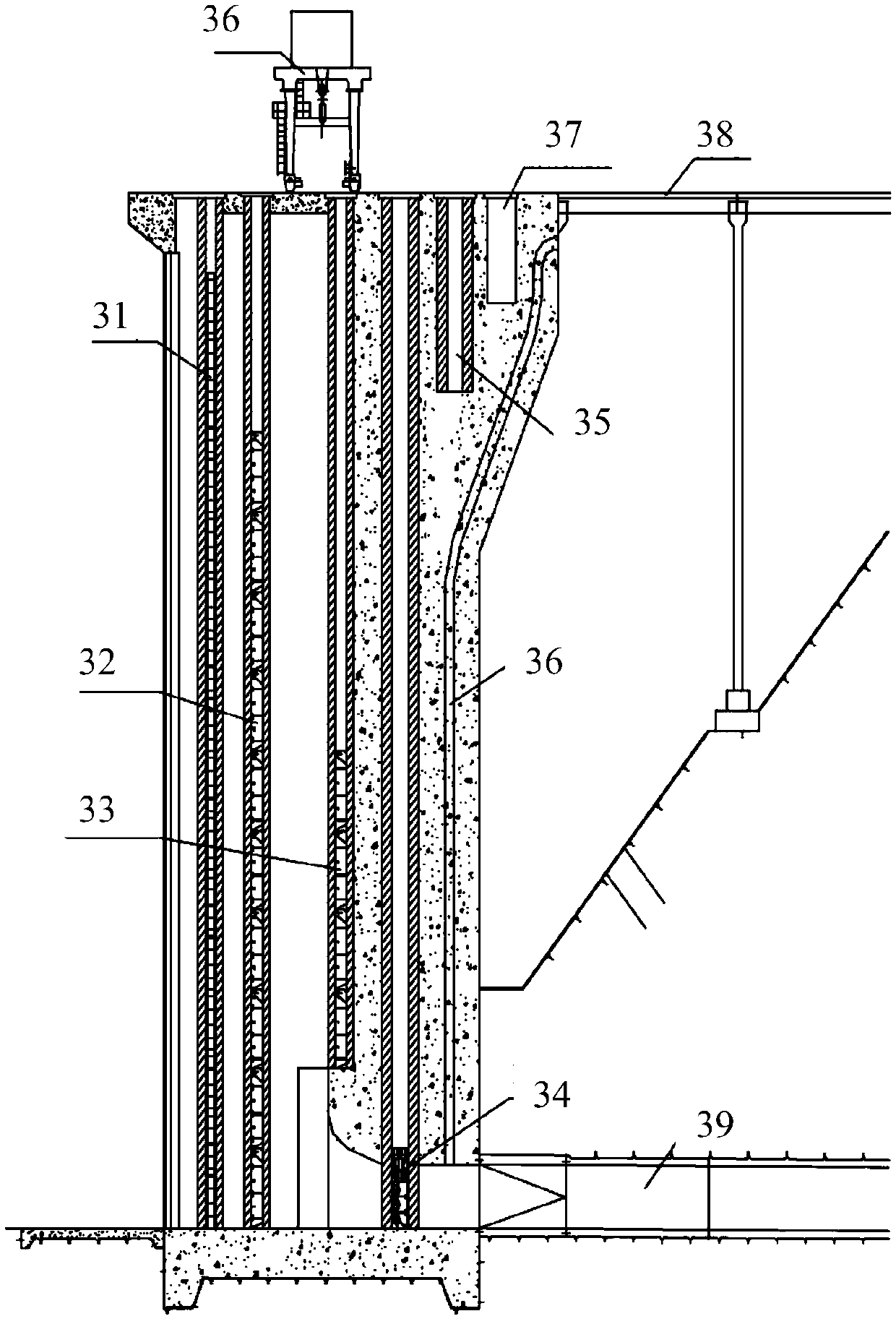

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] Such as Figure 5 , 6 As shown, the layered water intake independent water inlet tower structure used in high water head power stations of the present invention includes a bottom plate 1, a tower body 2, grid piers 3, trash racks 5, stacking beam door slots 6, and stacking beam door leaves 11 , stacked beam door storage 7, accident inspection door slot 8, ventilation hole 9, accident inspection maintenance gate 16, water diversion tunnel 14, trash rack 5 located in grid pier 3, stacked beam door slot 6, stacked beam door storage 7, accident inspection and repair The door slot 8 and the ventilation hole 9 are located in the tower body 2, and the multiple grid piers 3 located at the water inlet are connected by the beam 4 in turn to form a curved polygonal trash rack frame structure protruding toward the water inlet direction. Trash racks...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Maximum width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com