A Quick Locking Mechanism for Back Corrugation Formed in Semi-Solid Form

A semi-solid forming and locking mechanism technology, applied in the field of clamping tooling, can solve the problems of inconvenient installation and disassembly, waste of time for installation and disassembly, complex structure of back corrugated fixing, etc., to achieve fast locking and improve fixing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

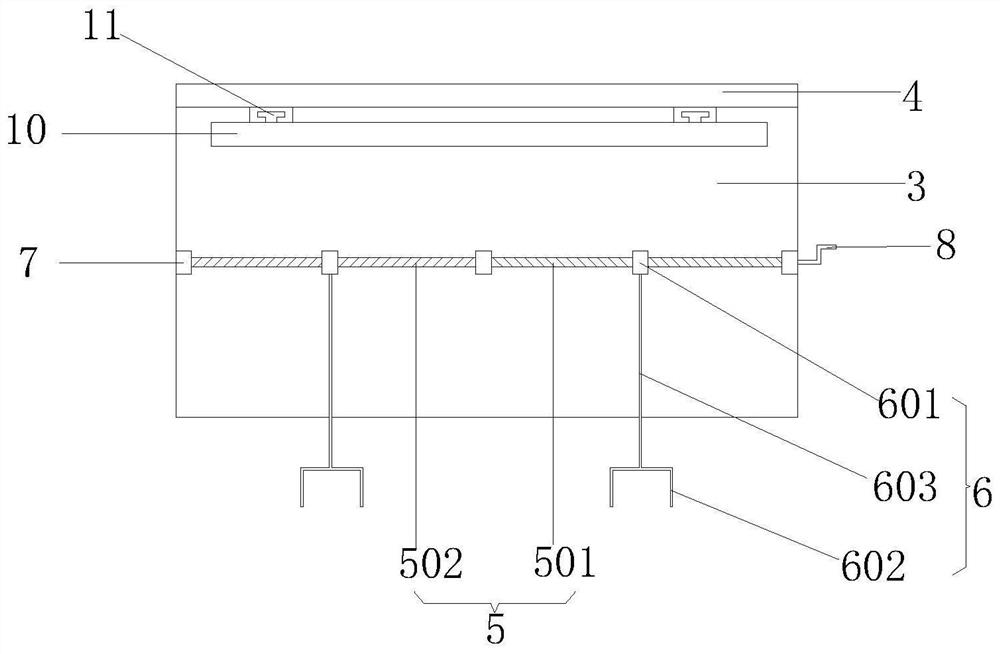

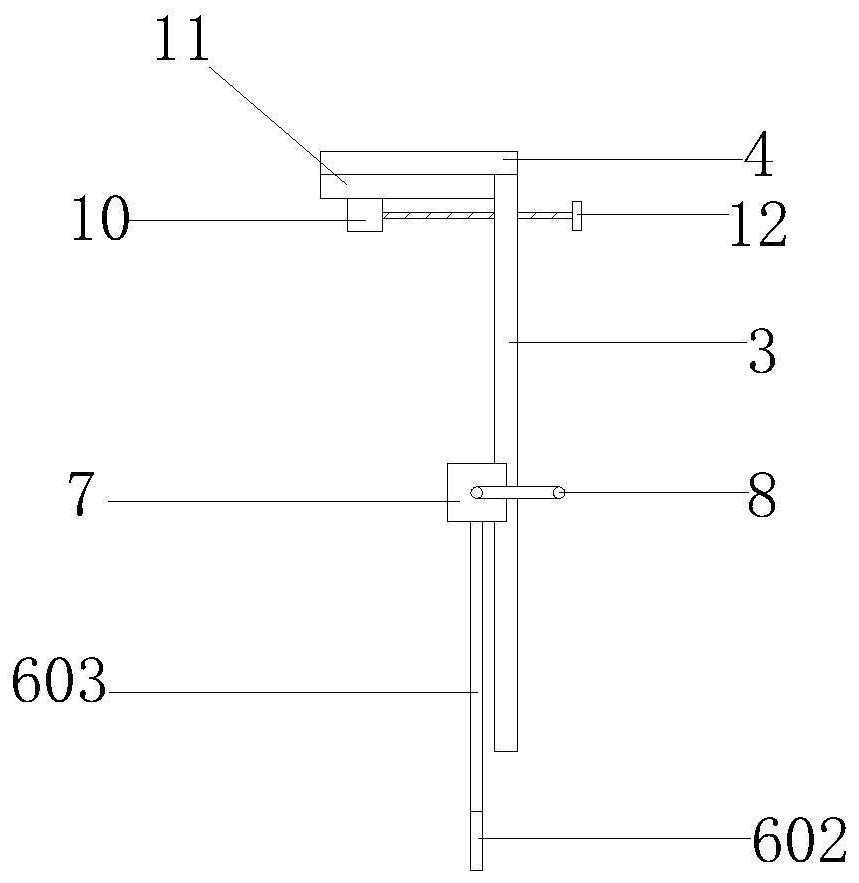

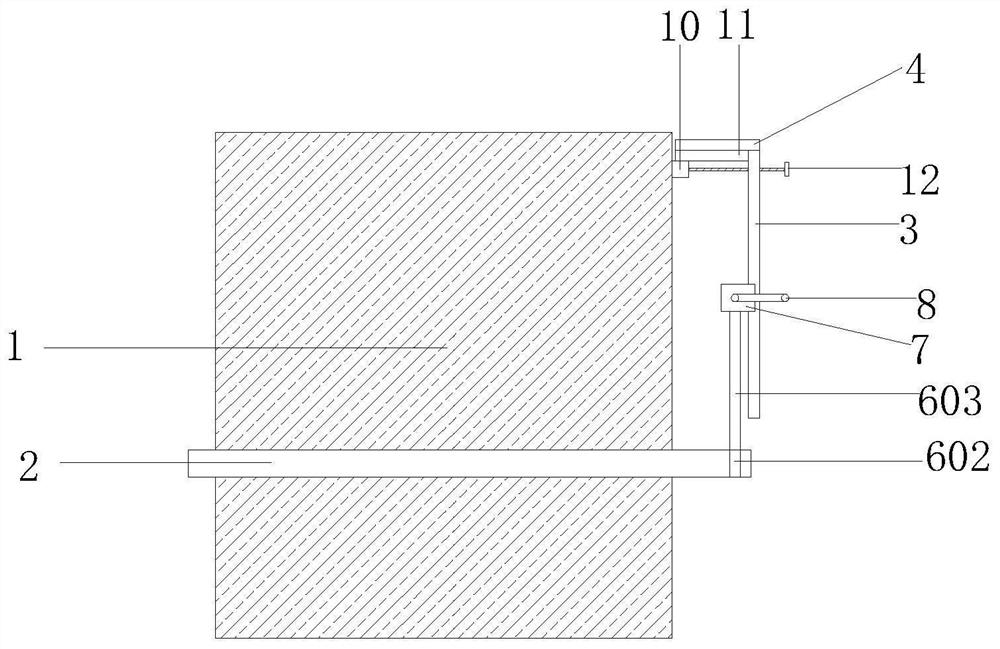

[0041] Such as Figure 1~4 As shown, in this embodiment, a semi-solid-formed back flute fast locking mechanism includes a main body plate 3 and a two-way screw 5, the two-way screw 5 is rotationally connected to the main body plate 3, and the two-way screw 5 includes a fixed connection The thread direction of the first lead screw 501 and the thread direction of the second lead screw 502 are opposite.

[0042] The length of the first lead screw 501 is equal to the length of the second lead screw 502 , and the pitch of the first lead screw 501 is equal to the pitch of the second lead screw 502 . In this embodiment, the first lead screw 501 and the second lead screw 502 are integrally formed. In other embodiments, the first lead screw and the second lead screw may also be two separately formed lead screws, which are subsequently connected and fixed together to form a bidirectional lead screw.

[0043] Fixing pieces 6 are installed on the first lead screw 501 and the second lead...

Embodiment 2

[0057] The difference between the second embodiment and the first embodiment is that two slide rails 11 are arranged above the top plate 4, and the auxiliary flute 10 is slidably connected with the slide rails 11, such as Figure 5 As shown, the top plate 4 is provided with a driving bolt 12 , the driving bolt 12 is threadedly connected with the top plate 4 , and the driving bolt 12 is rotatably connected with the auxiliary flute 10 .

Embodiment 1

[0058] The rest of the structures and principles of Embodiment 1 and Embodiment 2 are the same. Compared with Embodiment 1, it is easier to manually rotate and drive the bolt 12 without being restricted by space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com