Wire coil distance deformation automatic detection device and detection method applying same

An automatic detection device and wire reel technology, applied in the direction of mechanical solid deformation measurement, mechanical gap measurement, etc., can solve the problems of uneven cylinder diameter, poor integrity, and excessive height difference of slats, etc., to achieve convenient and objective detection process , Reduce difficulty and risk, easy to use and flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

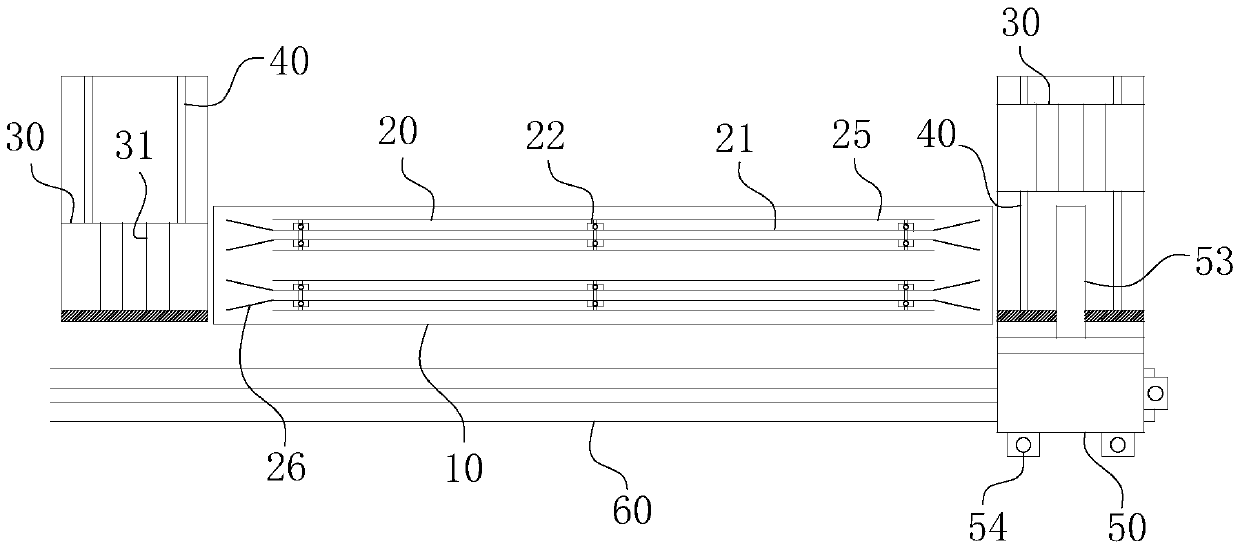

[0038] For ease of understanding, combined here Figure 1-5, the concrete structure and working mode of the present invention are further described as follows:

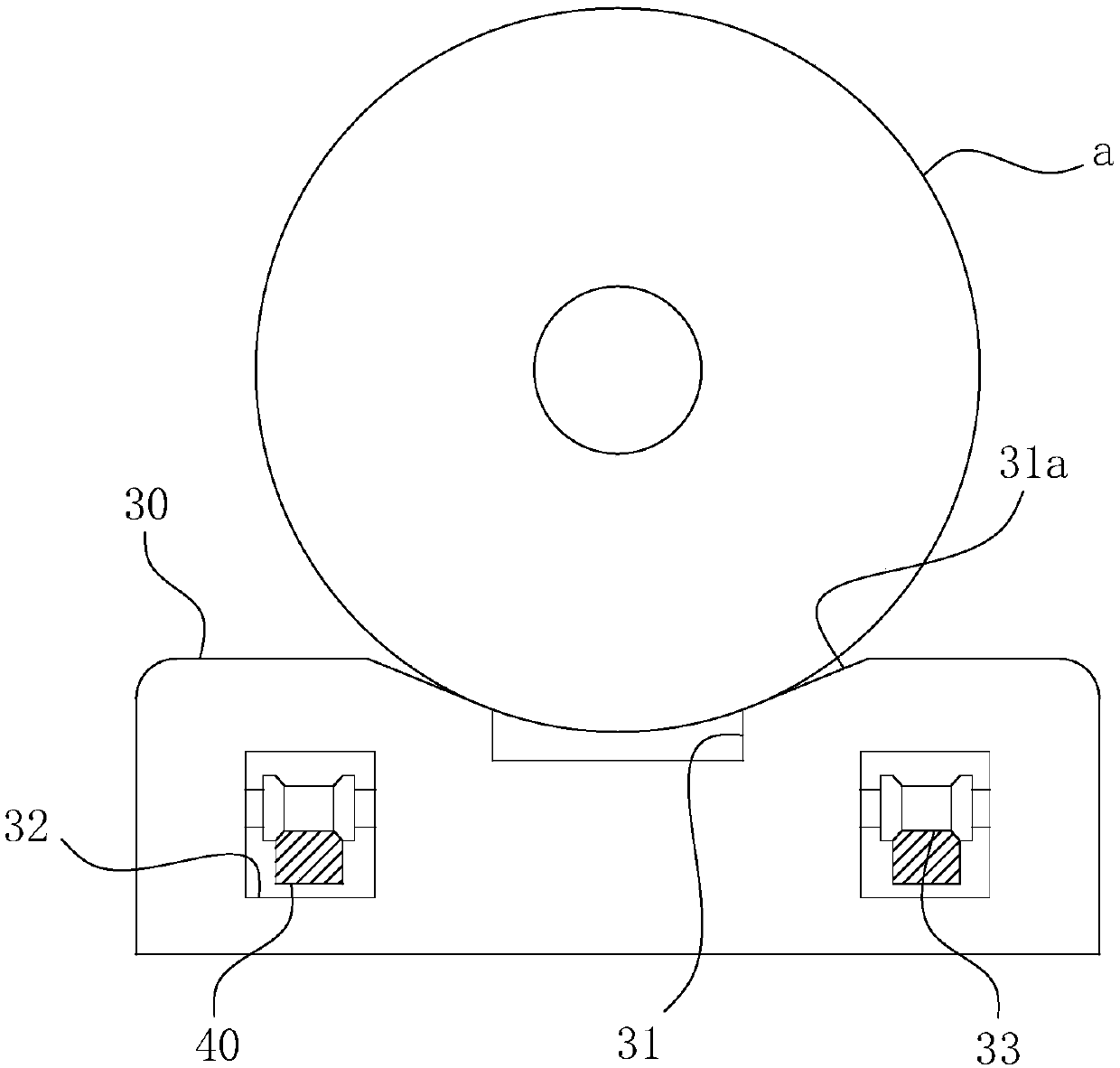

[0039] The specific structure of the present invention is as Figure 1-5 As shown, its main structure includes a base plate 10 with a detection belt 20, two sets of first guide rails 40, two sets of disk body positioning plates 30 located on each first guide rail 40, a set of second guide rails 60 and a set of second guide rails located on the second guide rails. A group of railcars 50 with positioning posts 53 on 60. in:

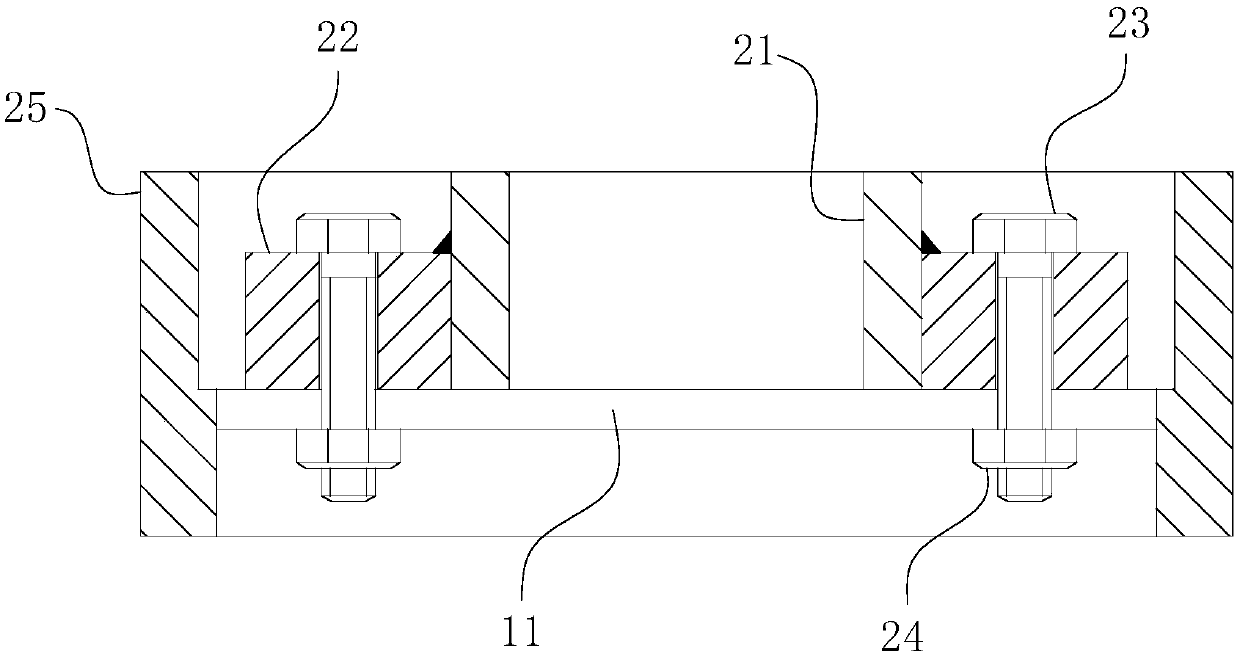

[0040] Detection band 20 is as the core component of the present invention, with Figure 1-2 Taking the structure as an example, the detection belt 20 includes four sets of detection plates 21 and four sets of limit plates 25 . along figure 1 In the direction shown, the detection zone 20 is subdivided into the first detection plate, the second detection plate, the third detection plate and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com