Monitoring system for cable force of magnetic flux sensors and preparation method of monitoring system

A magnetic flux sensor and cable force monitoring technology, applied in the direction of force measurement, bridge parts, bridge construction, etc. by measuring the change of magnetic properties of materials caused by applied stress, can solve the problem that the magnetic flux sensor does not form a reliable protection, the cable measurement range Insufficient and other problems, to achieve the effect of improving the anti-corrosion performance and improving the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the examples, which are only used to explain the present invention, and do not constitute a limitation to the protection scope of the present invention.

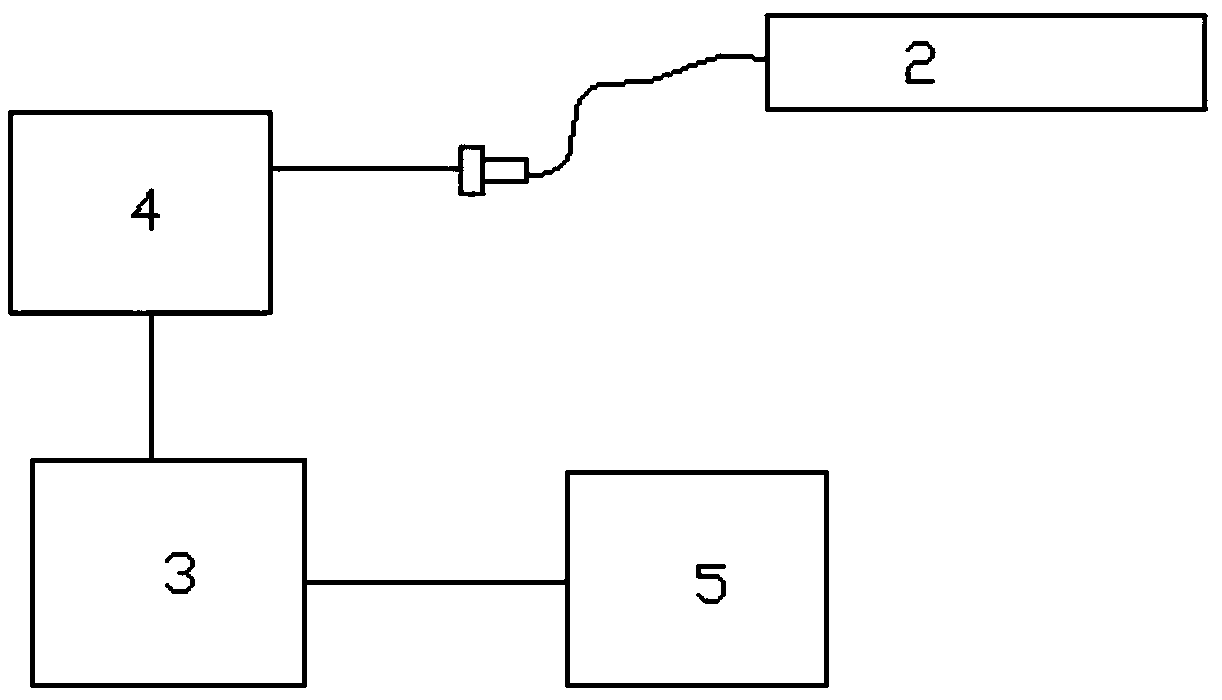

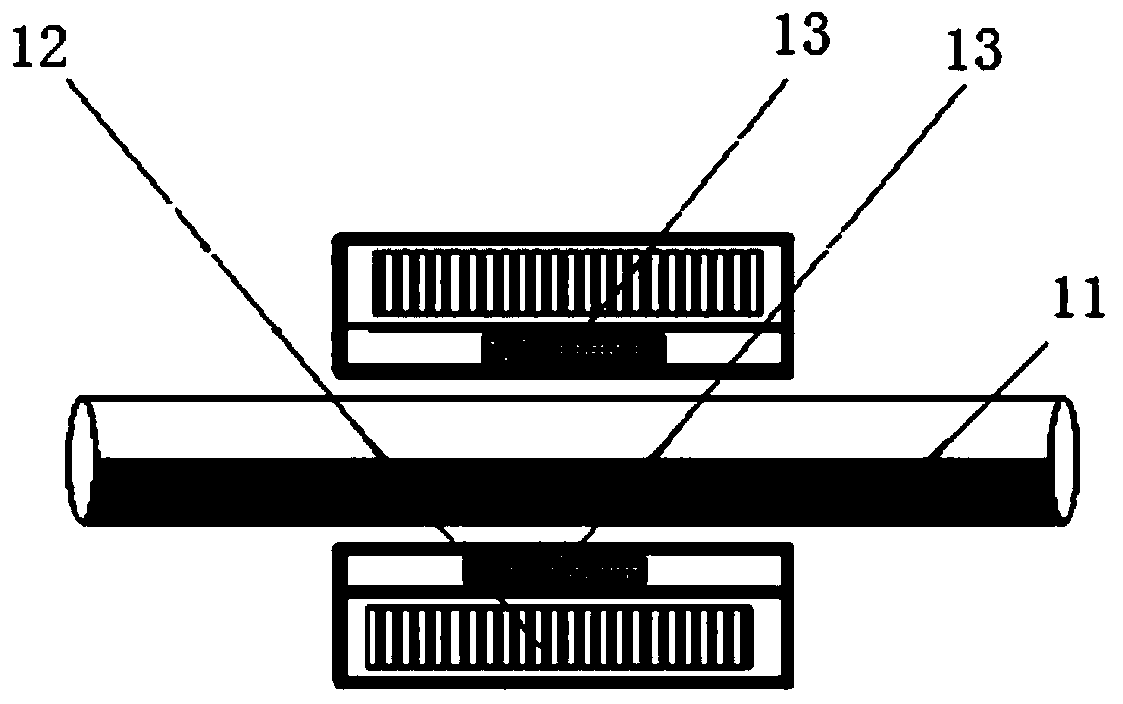

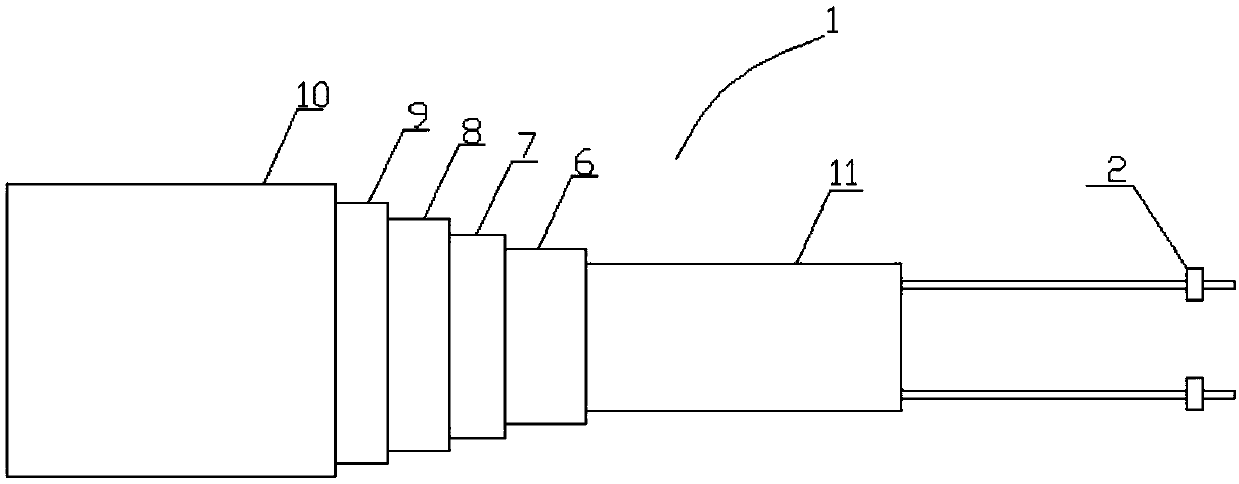

[0032] according to figure 1 , 2 , 3, this embodiment provides a magnetic flux sensor cable force monitoring system, including a cable body 1, a magnetic flux sensor 2, a magnetoelastic instrument 3, a switch junction box 4 and an acquisition system 5, and the cable body 1 consists of A number of steel wires are twisted, and an epoxy coating 6, a high-strength polyester tape 7, an inner layer HDPE8, an isolation layer 9 and an outer HDPE10 are arranged on the outside of the steel wire 11 from the inside to the outside; A magnetic flux sensor 2 is arranged on the steel wire, and the magnetic flux sensor 2 is fixed inside the steel wire; anchorages are installed at both ends of the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com