Flexible pressure sensor containing CNT composite organic material and preparation method of flexible pressure sensor

A technology of pressure sensors and organic materials, applied in the field of flexible pressure sensors containing CNT composite organic materials and its preparation, can solve the problems of unsuitable hot press pressure detection, unsatisfactory, small range, etc., and achieve the maximum utilization efficiency of industrial resources Minimization, cost reduction, physical volume, and low working condition requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

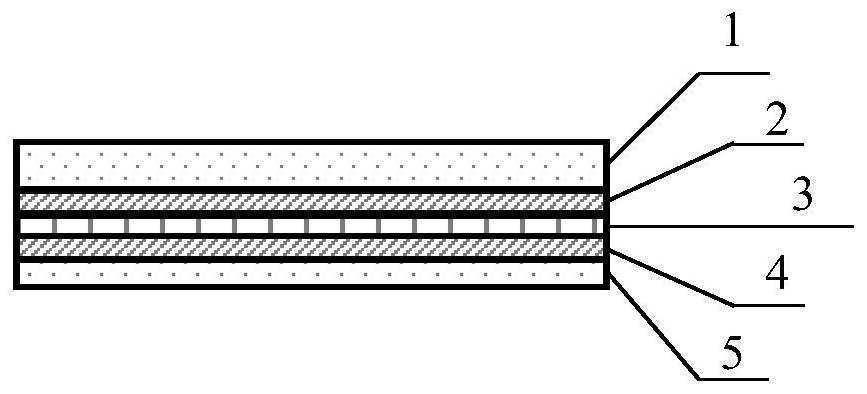

[0043] The flexible pressure sensor containing CNT composite organic material is composed of 5 layers, that is, the upper part is composed of polyimide flexible substrate and high-precision silver electrode fixed on the substrate, and the active sensing layer, high-precision silver electrode and polyimide The lower half consists of an imide flexible substrate. The electrodes of the upper part and the lower part are in a cross pattern. The polyimide base film has excellent stability, insulation and mechanical properties, and its temperature resistance is relatively good, it can adapt to a wide range of temperature changes, and it also has good corrosion resistance. The active sensing layer includes multi-walled carbon nanotubes and polymethyl methacrylate.

[0044] The specific preparation process is as follows: first, laser cut the polyimide flexible substrate into a rectangle of 30×18 cm. Spread the cut polyimide substrate on the workbench, then install the screen printing ...

Embodiment 2

[0048] The flexible pressure sensor comprising CNT composite organic material of the present invention is composed of 5 layers, that is, the upper part is composed of a PDMS flexible substrate and a high-precision silver electrode fixed on the substrate, and an active sensing layer, a high-precision silver electrode and a PDMS The lower part consists of a flexible substrate. The electrodes of the upper part and the lower part are in a cross mode. The advantages of PDMS film are: low Young's modulus, good flexibility and stretchability, strong corrosion resistance, good transparency and stability in a wide range of operating temperatures, and can be used for large-area transparent The substrate material of flexible electronic devices or thermally stable devices; it is easy to combine with electronic materials, so that electronic materials can be fixed on its surface, and PDMS can be prepared into a structure with a certain geometric shape according to needs to improve its ducti...

Embodiment 3

[0053] The preparation process of the active sensing layer slurry is as follows: Polymethyl methacrylate PMMA (5wt%) having a high molecular weight can be dissolved in diethylene glycol butyl ether acetate relatively quickly under 100° C. heating magnetic stirring; Diethylene glycol butyl ether acetate is used as an ink solvent in printing processes because of its low volatility and high boiling point. Use a homogenizer for high-speed stirring to disperse the multi-walled carbon nanotubes in butyl acetate to form a butyl acetate-based multi-walled carbon nanotube solution. The detailed process of the high-speed stirring of the homogenizer is 1000r / min to stir and mix the slurry for 15 minutes , wait for the slurry to cool down, and then stir in vacuum at a speed of 300r / min for 3 minutes. A 10% butyl acetate-based multi-walled carbon nanotube (MWCNT) solution was then added to the PMMA solution. The dispersion of carbon nanotubes in resins has always been a challenge in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com