A quick detachable busway

A bus duct and fast technology, applied in the field of bus duct, can solve the problems of inconvenient disassembly, complicated fixing method of the flame retardant partition and the side plate of the bus duct, low use efficiency, etc. The effect of replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

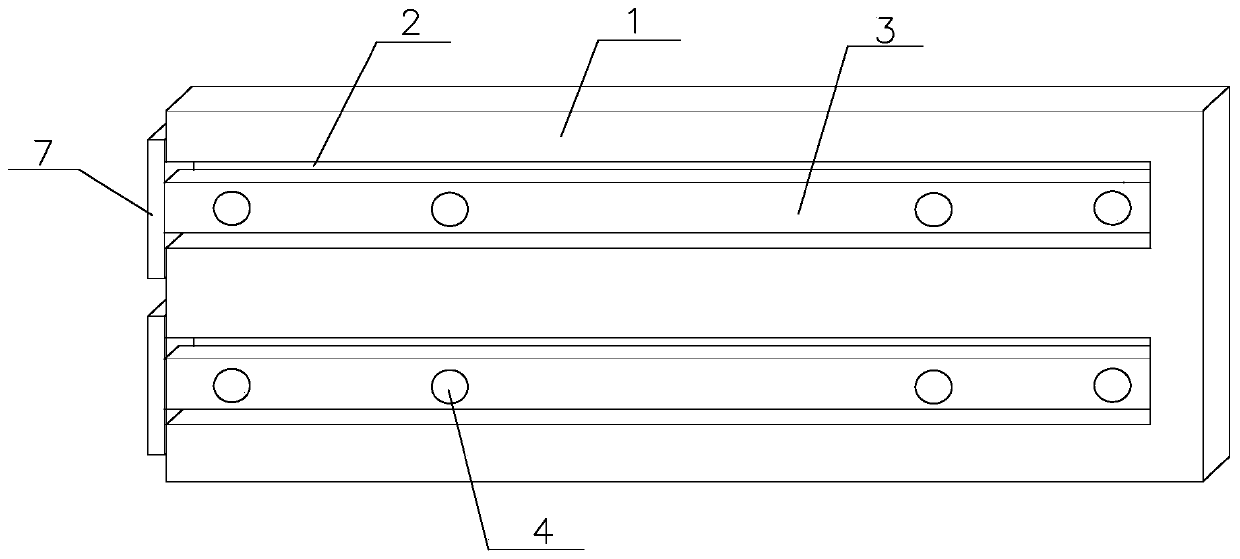

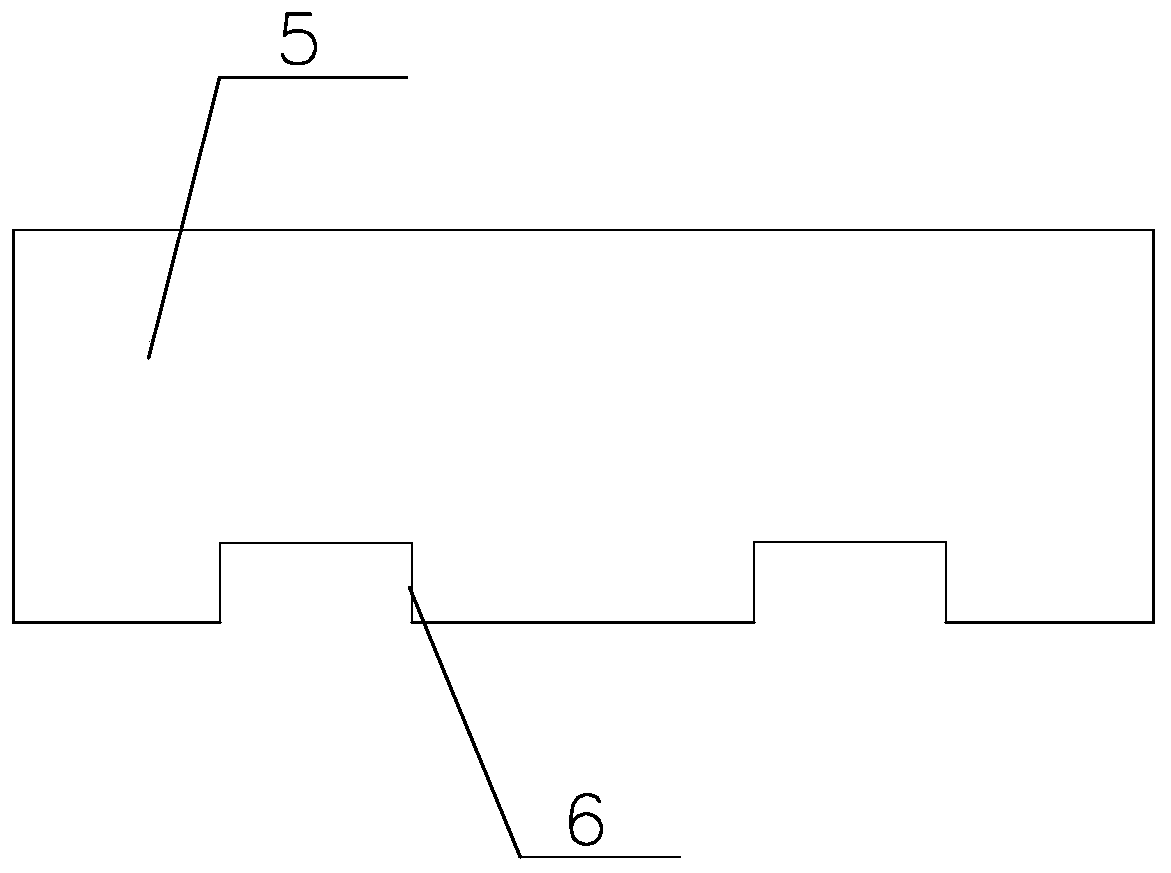

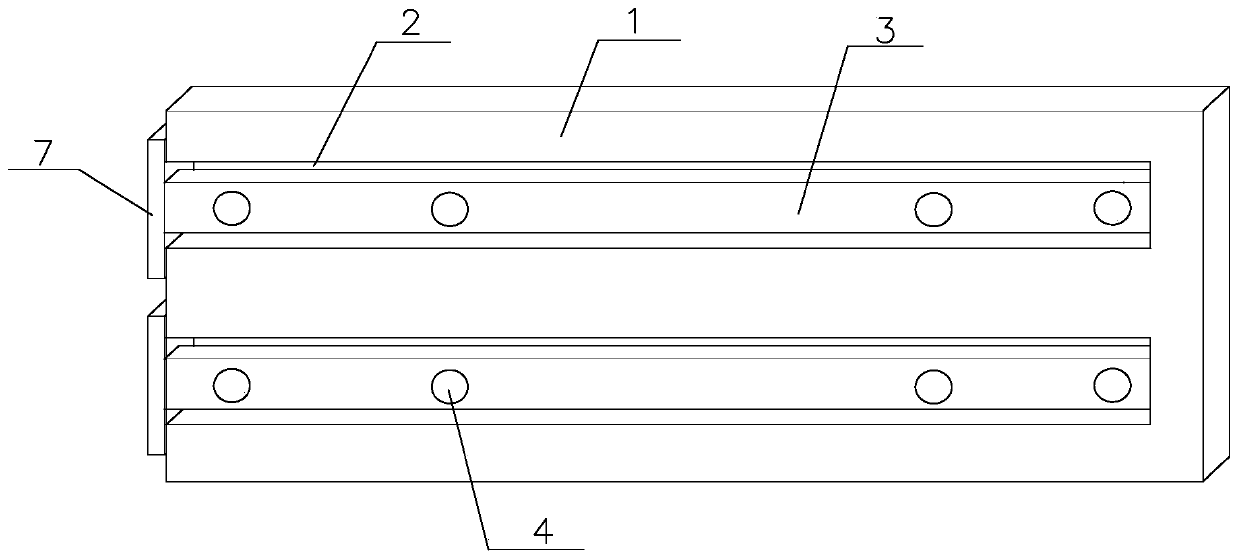

[0026] Such as Figure 1~2 As shown, a quick-detachable bus duct of the present invention includes a bus duct side plate 1 and a flame-retardant partition 5. Two first grooves 2 parallel to each other are arranged on the bus duct side plate 1. The first groove One end of 2 is in the side plate 1 of the bus duct, and the other end runs through one end of the side plate 1 of the bus duct. A connecting plate 3 is arranged in the first groove 2, and one end of the connecting plate 3 is connected with the spring, and the other end of the spring is connected with the first The groove 2 is connected to one end of the side plate 1 of the bus duct, and the other end of the connecting plate 3 is outside the first groove 2. Under the action of the spring, the connecting plate 3 moves along the straight line where the first groove 2 is located; the connecting plate 3 A through hole 4 for connecting the flame-retardant partition 5 is provided on the top, and the connecting plate 3 is drive...

Embodiment 2

[0028] A quick-detachable busway. On the basis of Embodiment 1, the connecting plate 3 is vertically connected with a positioning plate 7 on one end outside the side plate 1 of the busway. The positioning plate 7 is outside the side plate 1 of the busway. The positioning plate 7 An iron-absorbing layer is provided on the surface in contact with the side plate 1 of the bus duct, and the positioning plate 7 is fixedly connected with the side plate 1 of the bus duct through the iron-absorbing layer. The length of the connecting plate 3 is the same as that of the first groove 2 .

Embodiment 3

[0030] A quick-detachable bus duct, in the case of Embodiment 2, the diameter of the second groove 6 is the same as the diameter of the through hole 4 , and the depth of the second groove 6 is the same as the length of the through hole 4 . The height of the connecting plate 3 is two-thirds of the height of the first groove 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com