Granulator with bearing chamber protection device

A protective device and granulator technology, applied in the direction of granulating raw materials, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as sealing ring deformation, damaged bearings, etc., to reduce maintenance costs and stabilize equipment Yield and economic benefits are remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

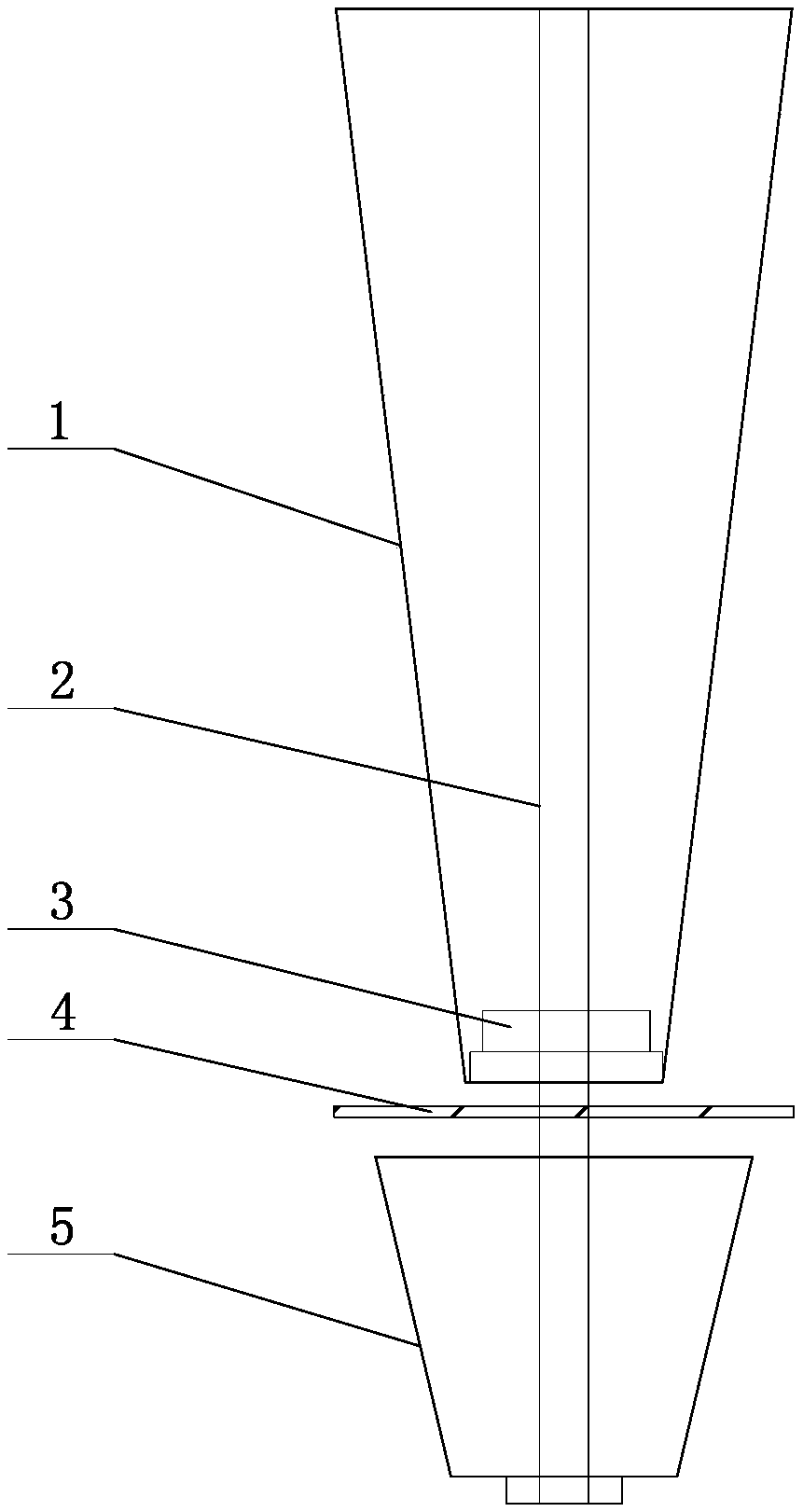

[0019] Such as figure 1 As shown, the granulator with bearing chamber protection device according to the present invention includes a granulator nozzle 5, the granulator nozzle 5 is installed on the granulator shaft 2, and a bearing chamber 1 is arranged above the granulator nozzle 5 A bearing 3 is installed at the bottom of the bearing chamber 1, and a baffle plate 4 is arranged between the nozzle 5 of the granulator and the bearing chamber 1. The baffle plate 4 is set as a 304 stainless steel baffle plate. A sealing ring is provided between the bottom of the bearing chamber 1 and the shaft 2 of the granulator, and the baffle plate 4 is located below the sealing ring, and the distance between the material baffle plate 4 and the sealing ring is 15 mm to 30 mm. The sealing ring is set as an O-shaped sealing ring. The distance between the baffle plate 4 and the sealing rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com