Power generator carbon brush frame intelligent assembling production equipment and production line

A technology of production equipment and carbon brush holder, applied in the field of intelligent manufacturing equipment, can solve the problems of inability to guarantee strict and consistent testing standards, inability to guarantee product quality consistency, and high error rate in data entry, so as to maintain industry competitiveness and eliminate human-made abnormalities , The effect of optimizing the industrial structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

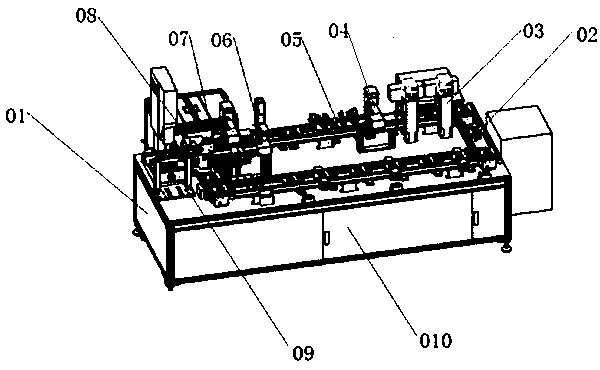

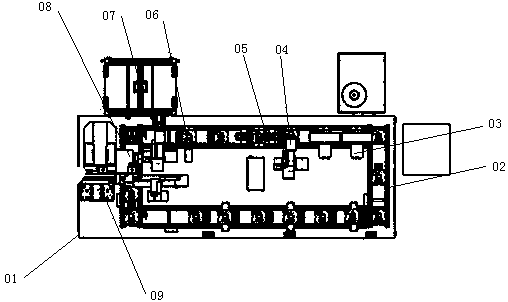

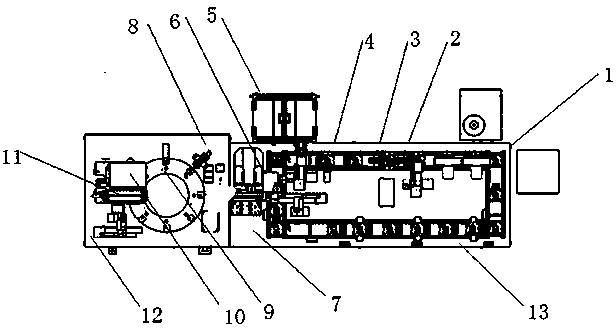

[0021] like Figure 1-2 As shown, a generator carbon brush holder intelligent assembly production equipment, including frame 01, jig circulation assembly 02, welding machine 03, thread trimming mechanism 04, first CCD camera assembly 05, second CCD camera assembly 06, Back cover assembly assembly 07, ultrasonic welder 08, defective product automatic sorting table 09 and material box 010, the top side of frame 01 is equipped with fixture circulation assembly 02 through bolts, and one side of fixture circulation assembly 02 is passed through bolts Two welding machines 03 are installed, the outer side of the welding machine 03 is provided with a thread trimming mechanism 04, the outer side of the thread trimming mechanism 04 is provided with a first CCD camera assembly 05, and the bottom of the thread trimming mechanism 04 is equipped with a four-axis motion module through bolts , and the four-axis motion module is connected with the frame 01 through bolts, which can facilitate t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com