Prefabricated laminated slab forming formwork

A technology for forming molds and laminated plates, applied in the direction of molds, etc., can solve the problems of increasing separation area, which is not conducive to the separation operation of prefabricated laminated plates and side molds, etc., and achieves the effect of improving the molding effect and the casting molding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

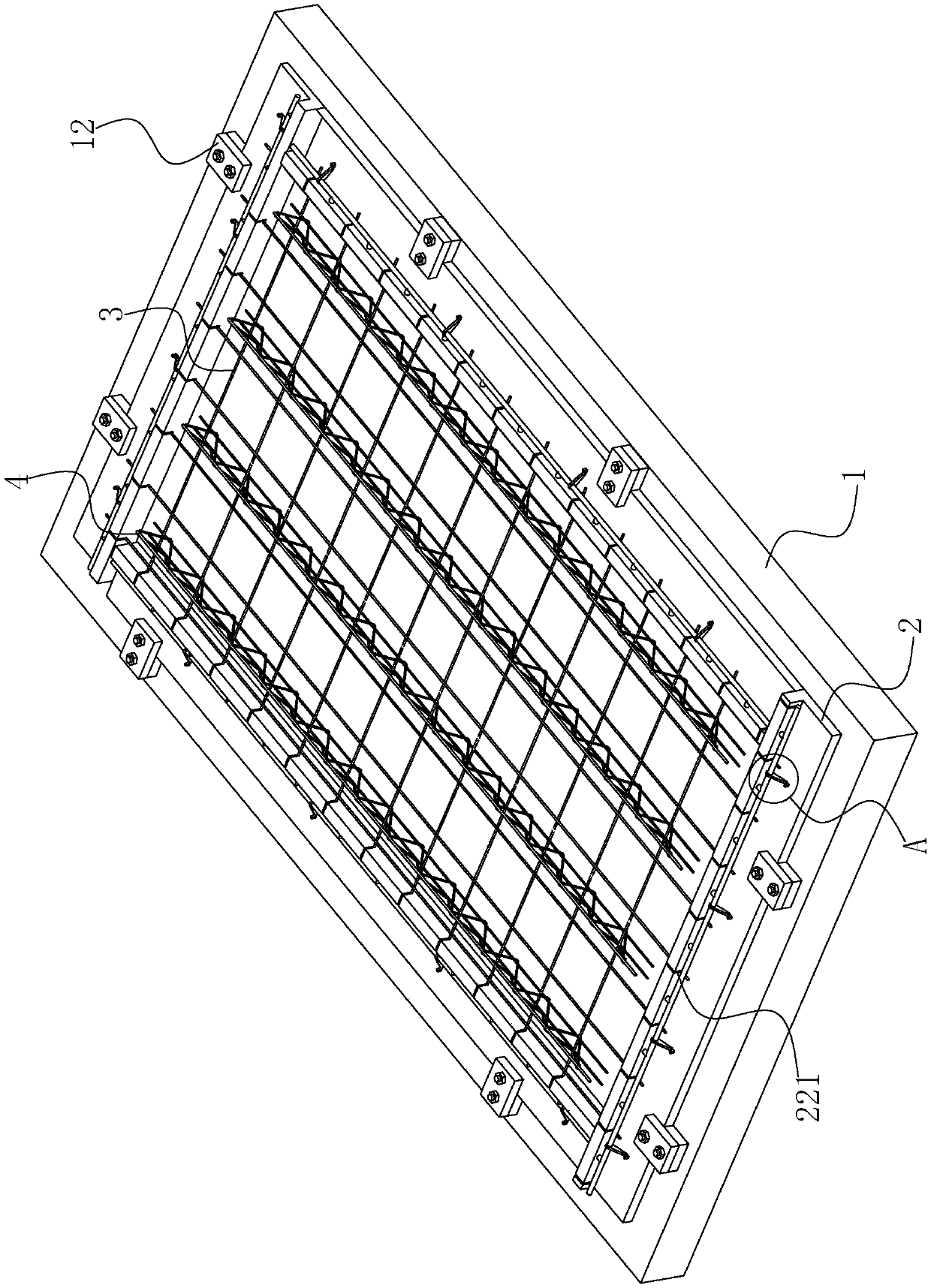

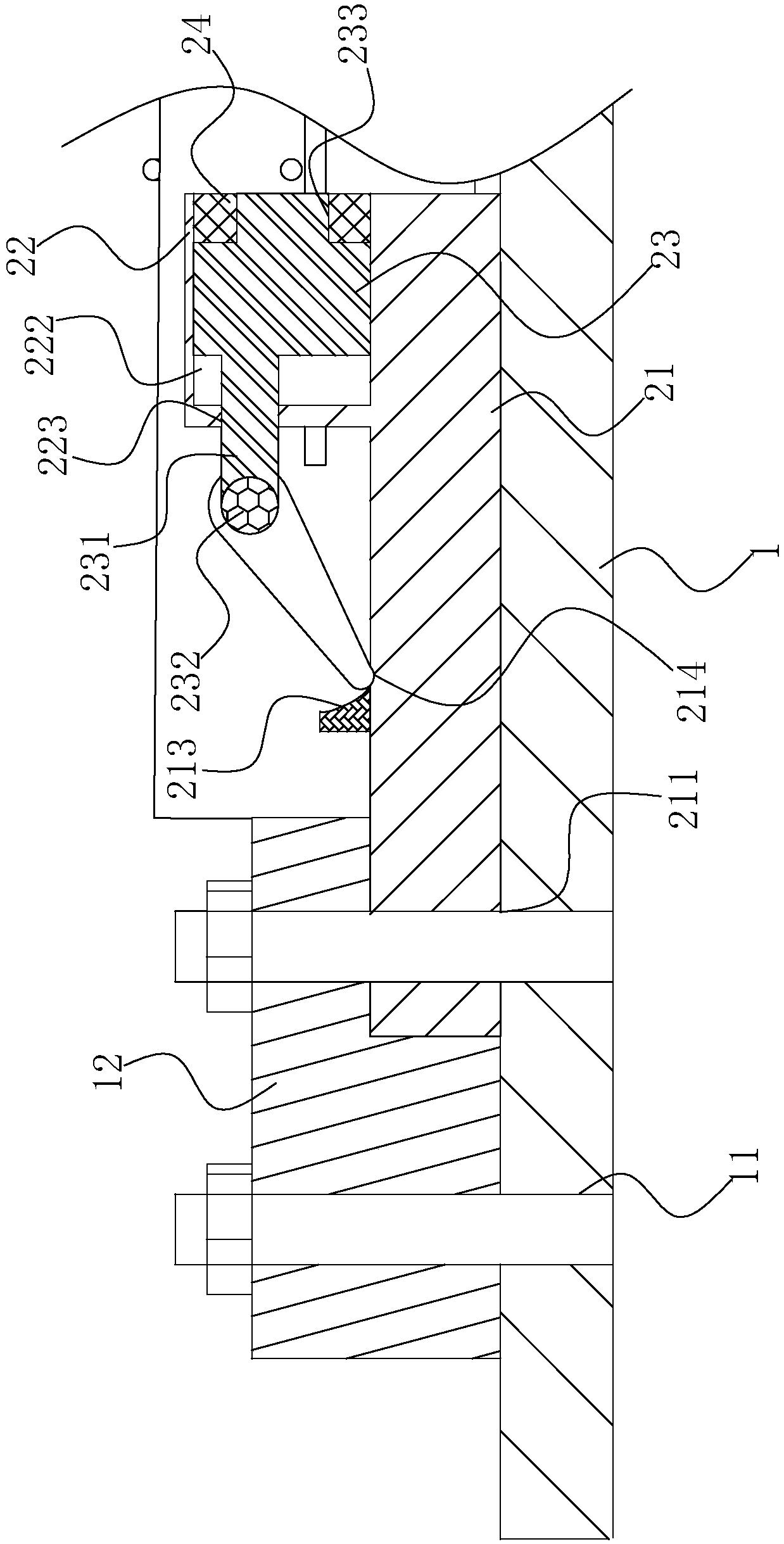

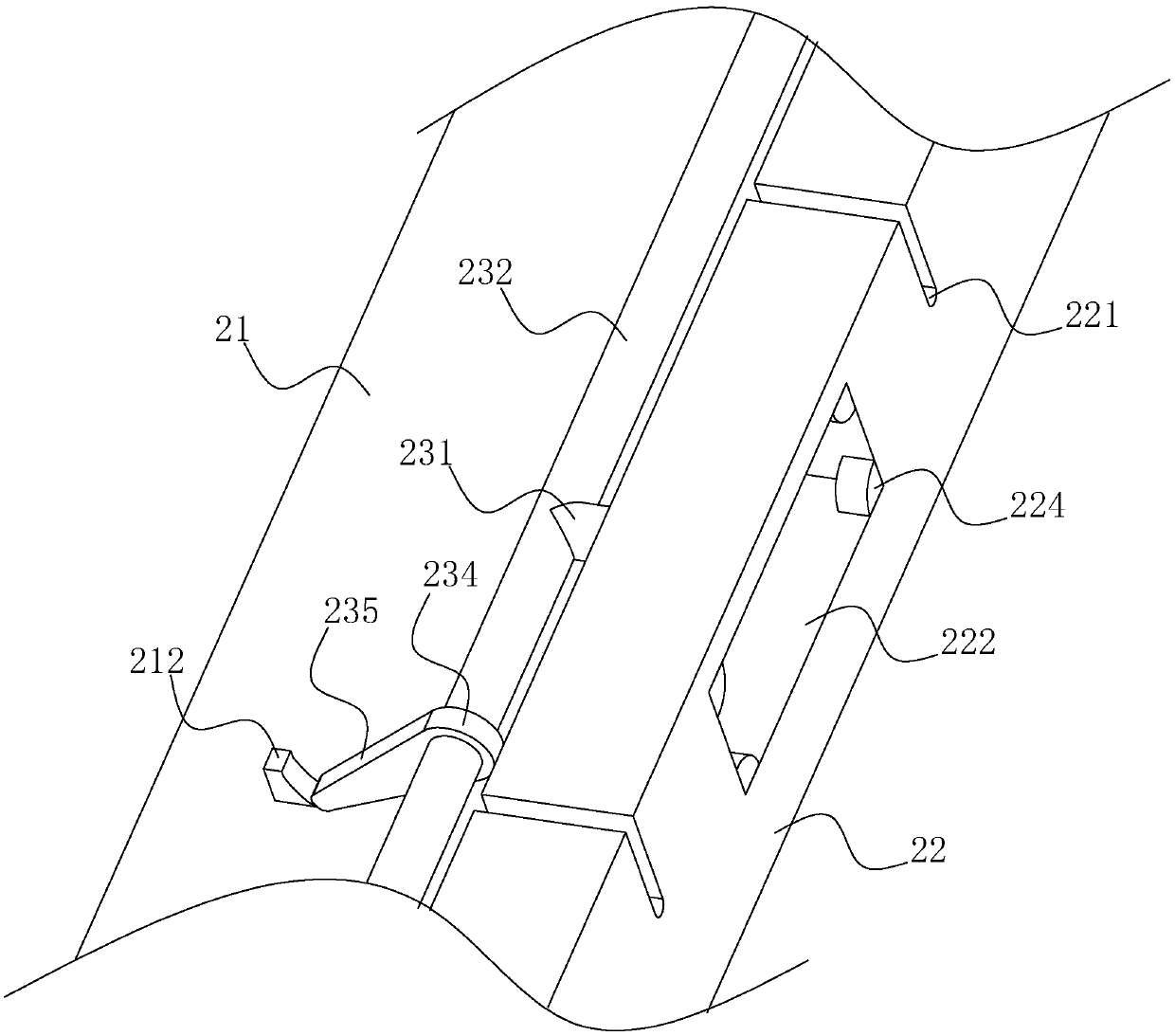

[0035] Embodiment, a kind of prefabricated laminated board forming mold, such as figure 1 , 2 As shown, it includes a mold table 1, a number of side molds 2 enclosed in a closed frame shape and installed and fixed on the mold table 1, and steel mesh 3 and truss steel bars placed on the mold table 1 within the enclosure of the side mold 2 4. The side formwork 2 is reserved with a relief slot 221 for the end of the reinforcement mesh 3 to pass through. The side mold 2 includes a bottom mold 21 and a side mold 22 integrally formed in an L shape. The bottom mold 21 is horizontally fixed on the mold table 1. The side mold 22 is located on the side of the bottom mold 21 adjacent to the reinforcement mesh 3. The side mold 22 faces the reinforcement mesh 3. One side is horizontally provided with sliding grooves 222, and several sliding grooves 222 are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com