Mechanical press crankshaft connection rod fastening device

A technology of mechanical presses and crankshaft connecting rods, applied in the field of mechanical presses, can solve problems such as the loosening of double-ended studs and nuts, the failure and loosening of threaded connections between double-ended studs and nuts, and the reduction of pre-tightening force, etc., to achieve Ensure the operation accuracy and safety, improve product quality, and improve the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

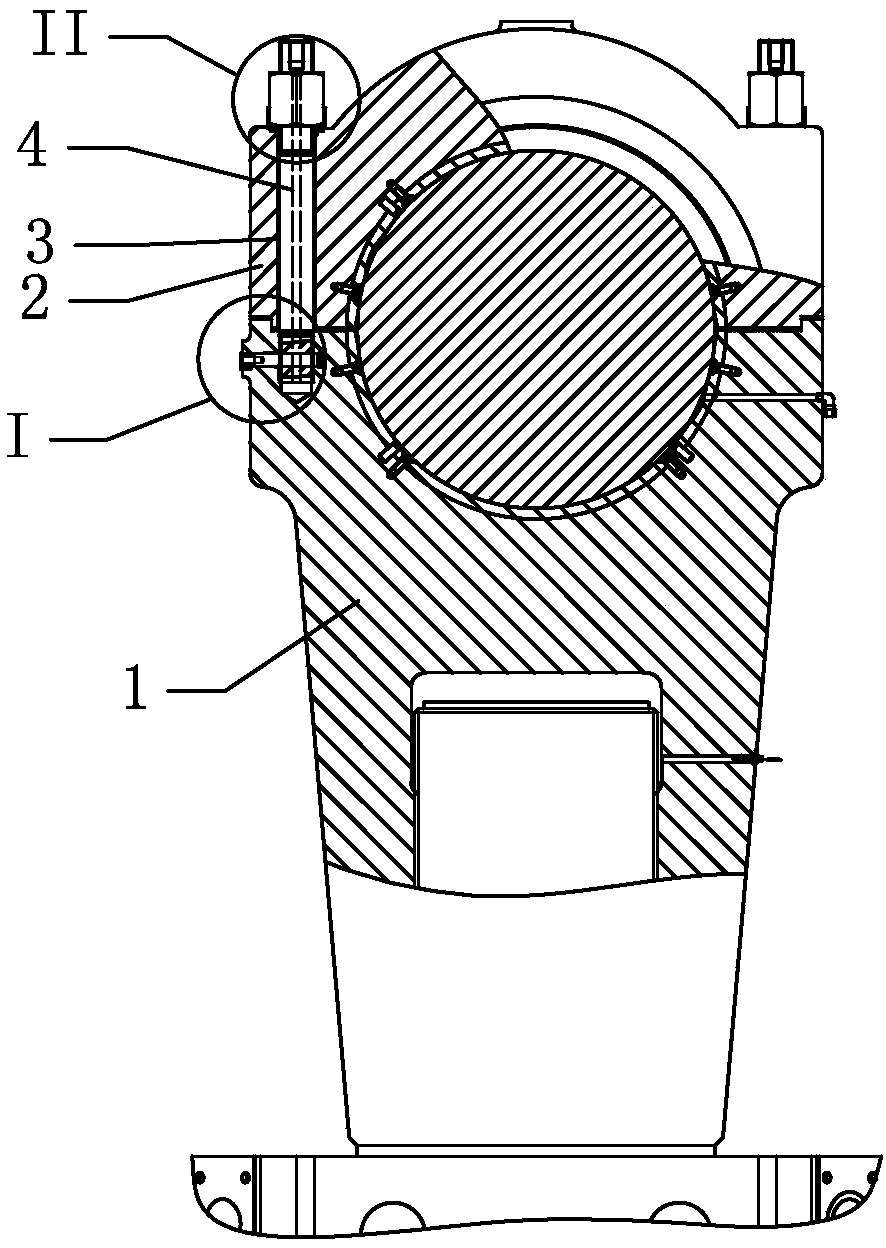

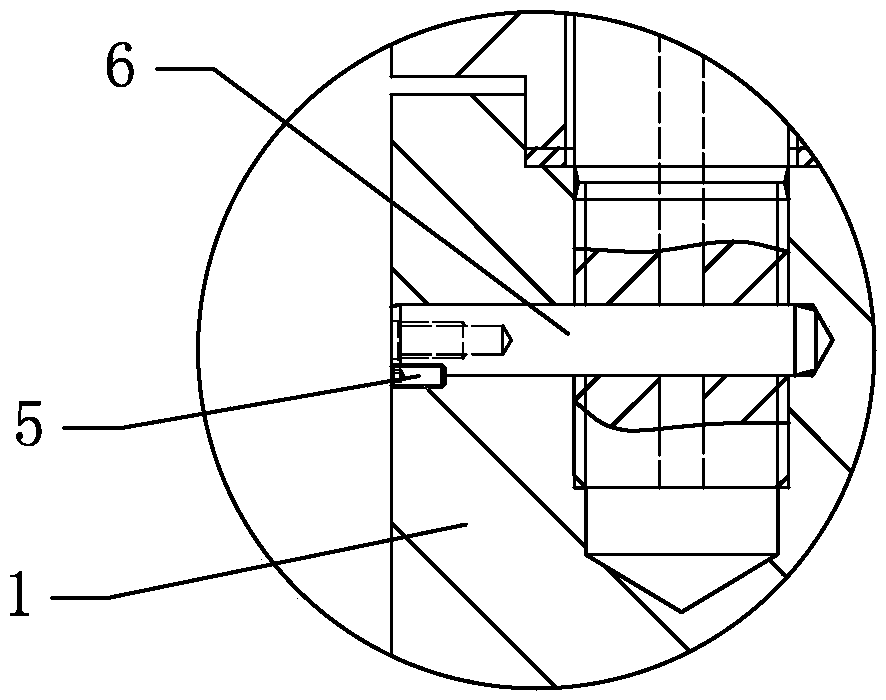

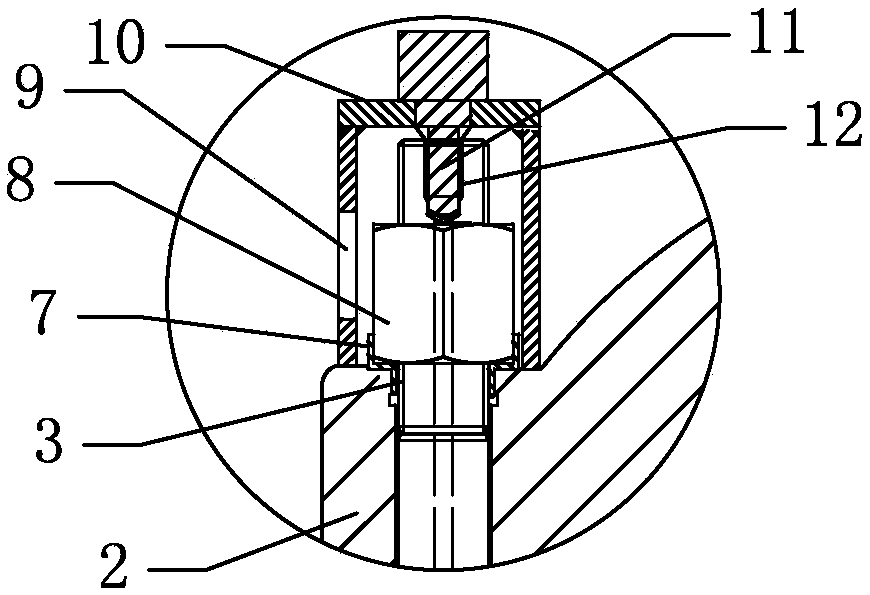

[0030] Such as Figure 1-7 As shown, a mechanical press crankshaft connecting rod fastening device is used to connect the connecting rod cover 2 and the connecting rod body 1. The connecting rod cover 2 has a light hole inside, and the connecting rod body 1 has an internal thread hole. Between the connecting rod cover 2 and the connecting rod body 1, a number of threaded connecting rods are provided through the internally threaded holes, and nuts 8 respectively pierced through the shafts of the threaded connecting rods. A heating channel 4 is arranged inside the threaded connecting rods. A threaded hole 12 is provided at the end where the heating passage 4 of the threaded connector communicates with the outside world. The threaded hole 12 communicates with the heating passage 4. A locking passage is provided in the vertical internal threaded hole in the connecting rod body 1. A locking device cooperating with the threaded connecting rod is provided in the channel, and a stretc...

Embodiment 2

[0037] This embodiment is a replacement for the locking channel and locking device in Embodiment 1.

[0038] Such as Figure 8-9 As shown, this embodiment is a replacement for the locking channel and the locking device inside it in the first embodiment.

[0039] The above-mentioned locking channel includes a stepped hole, and the stepped hole communicates with the internally threaded hole in the connecting rod body 1 through a fan-shaped groove. The inner wall of the stepped hole is provided with threads close to the outer wall section of the connecting rod body 1, and is far away from the outer wall section of the connecting rod body 1. There is an internal circular hole, and the above-mentioned stepped hole communicates with the internal threaded hole of the connecting rod body 1 through a fan-shaped groove. One end of the fan-shaped groove is a fan-shaped surface, and the other end is a plane. In the stepped hole, the fan-shaped groove is provided with a fan-shaped locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com