Composite face plate with wood-grained structure and for refrigerator and manufacturing method of composite face plate

A technology for composite panels and manufacturing methods, which is applied in chemical instruments and methods, synthetic resin layered products, patterns imitating natural patterns, etc., which can solve the problems of unsightly appearance, colloid pattern rollers that are not easy to gather heat, and pattern effects that are easy to lose And other problems, to achieve the effect of high degree of fineness, not easy to soften at high temperature, and difficult pattern effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

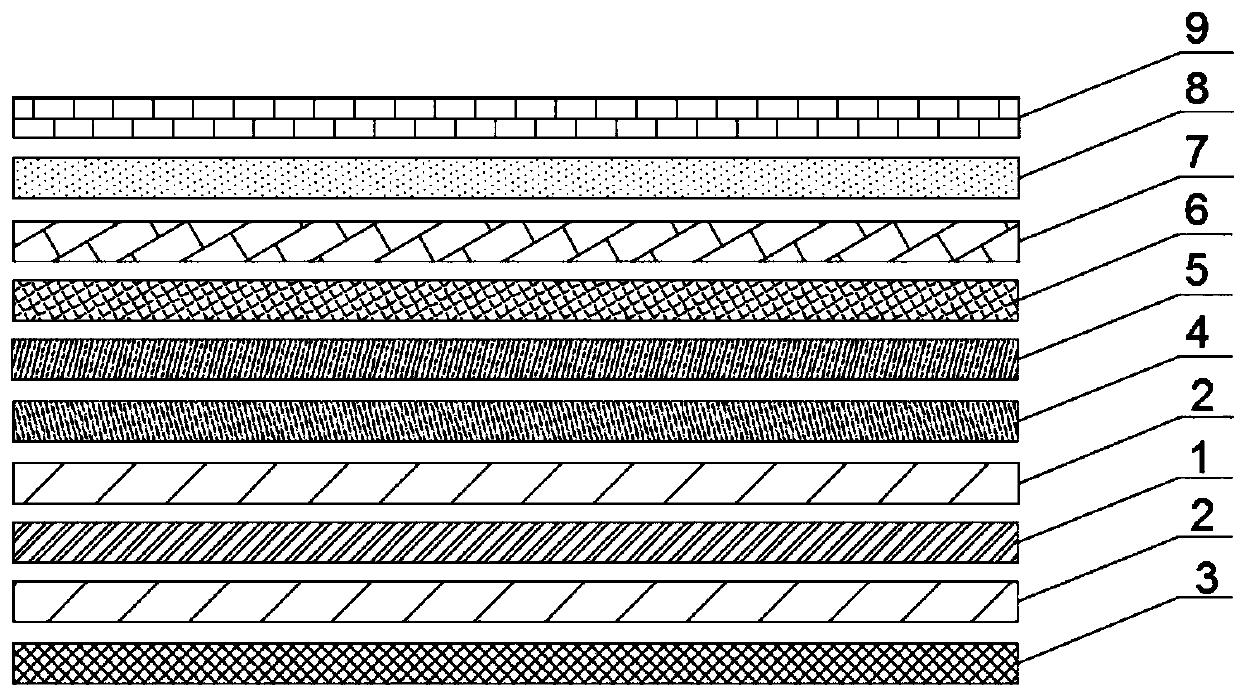

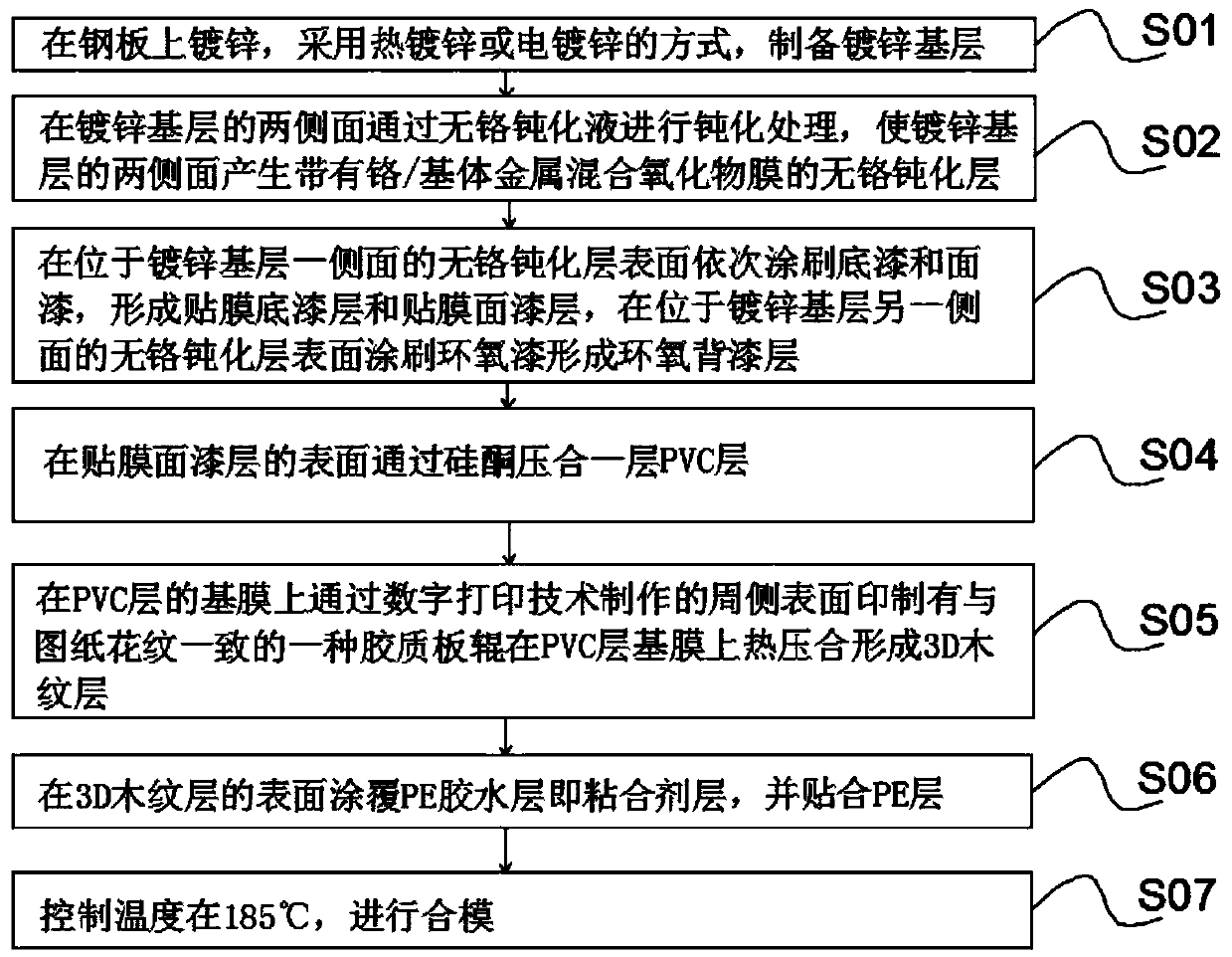

[0032] see figure 1 As shown, a composite panel for a refrigerator with a wood grain structure of the present invention and a manufacturing method thereof include a galvanized base layer 1, each of which is compounded with a chromium-free passivation layer 2 on both sides of the galvanized base layer 1, and a chromium-free passivation layer 2. On the surface of the layer 2, from the inside to the outside, a film primer layer 4, a film finish paint layer 5, a PVC layer 6, a 3D wood grain layer 7, an adhesive layer 8, a PE layer 9, and another chrome-free passivation layer are sequentially compounded. The surface of the chemical layer 2 is compounded with an epoxy back paint layer 3 .

[0033] Among them, PE layer 9, adhesive layer 8, 3D wood grain layer 7, PVC layer 6, film topcoat layer 5, film primer layer 4, epoxy back paint layer 3, chrome-free passivation layer 2, galvanized The thickness ratio of the base layer 1 is 2:1:2:2:1:1:3:2:5.

[0034] Among them, the PVC layer ...

Embodiment 2

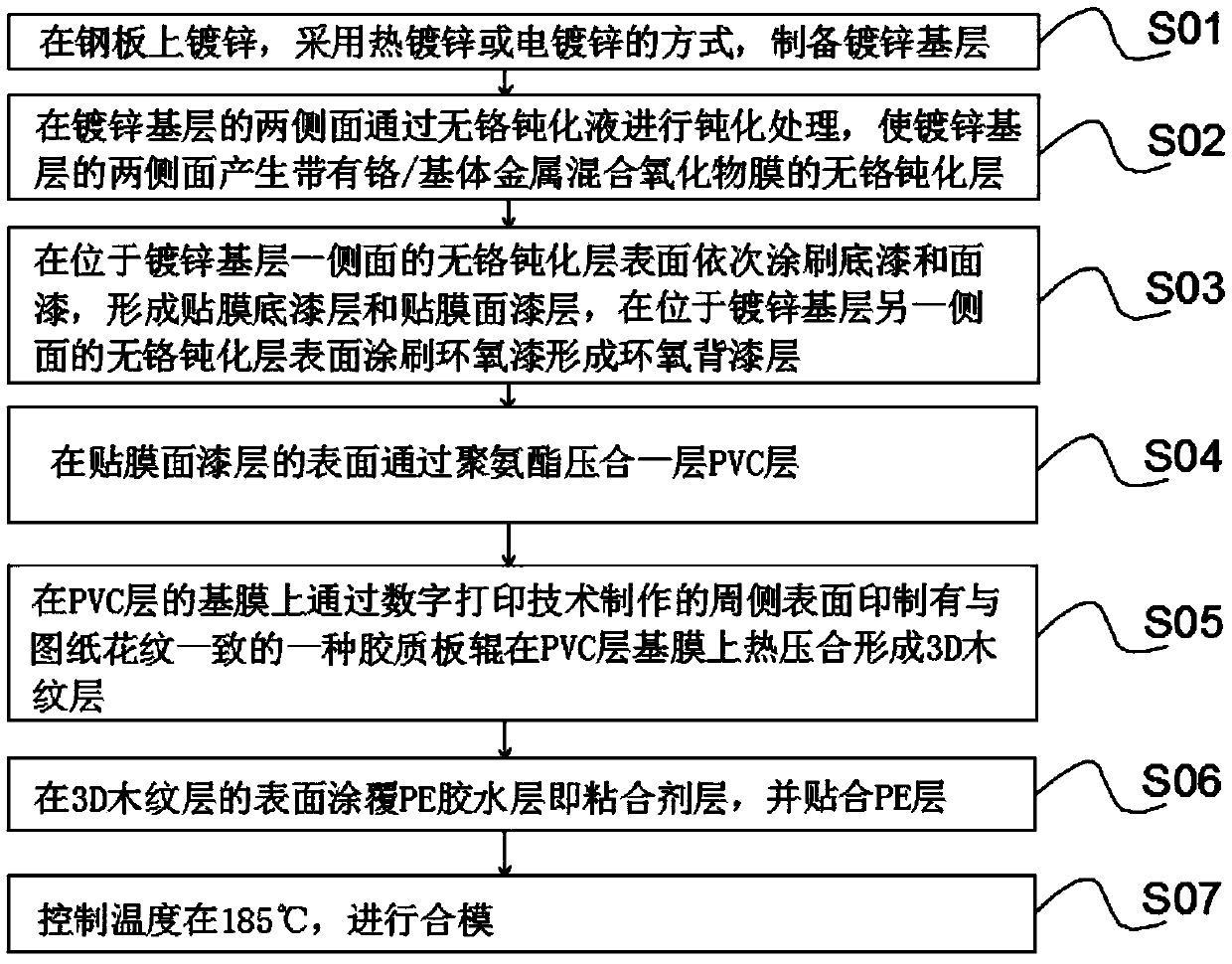

[0045] see figure 1 As shown, a composite panel for a refrigerator with a wood grain structure of the present invention and a manufacturing method thereof include a galvanized base layer 1, each of which is compounded with a chromium-free passivation layer 2 on both sides of the galvanized base layer 1, and a chromium-free passivation layer 2. On the surface of the layer 2, from the inside to the outside, a film primer layer 4, a film finish paint layer 5, a PVC layer 6, a 3D wood grain layer 7, an adhesive layer 8, a PE layer 9, and another chrome-free passivation layer are sequentially compounded. The surface of the chemical layer 2 is compounded with an epoxy back paint layer 3 .

[0046] Among them, PE layer 9, adhesive layer 8, 3D wood grain layer 7, PVC layer 6, film topcoat layer 5, film primer layer 4, epoxy back paint layer 3, chrome-free passivation layer 2, galvanized The thickness ratio of the base layer 1 is 2:1:2:2:1:1:3:2:5.

[0047] Among them, the PVC layer ...

Embodiment 3

[0058] see figure 1 As shown, a composite panel for a refrigerator with a wood grain structure of the present invention and a manufacturing method thereof include a galvanized base layer 1, each of which is compounded with a chromium-free passivation layer 2 on both sides of the galvanized base layer 1, and a chromium-free passivation layer 2. On the surface of the layer 2, from the inside to the outside, a film primer layer 4, a film finish paint layer 5, a PVC layer 6, a 3D wood grain layer 7, an adhesive layer 8, a PE layer 9, and another chrome-free passivation layer are sequentially compounded. The surface of the chemical layer 2 is compounded with an epoxy back paint layer 3 .

[0059] Among them, PE layer 9, adhesive layer 8, 3D wood grain layer 7, PVC layer 6, film topcoat layer 5, film primer layer 4, epoxy back paint layer 3, chrome-free passivation layer 2, galvanized The thickness ratio of the base layer 1 is 2:1:2:2:1:1:3:2:5.

[0060] Among them, the PVC layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com