Self-adjusting wiper driving arm

A driving arm and wiper technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc. It can solve the problems of damaged linkage parts wiper motor and wiper sticking to the windshield, so as to eliminate freezing and reduce damage The effect of the probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

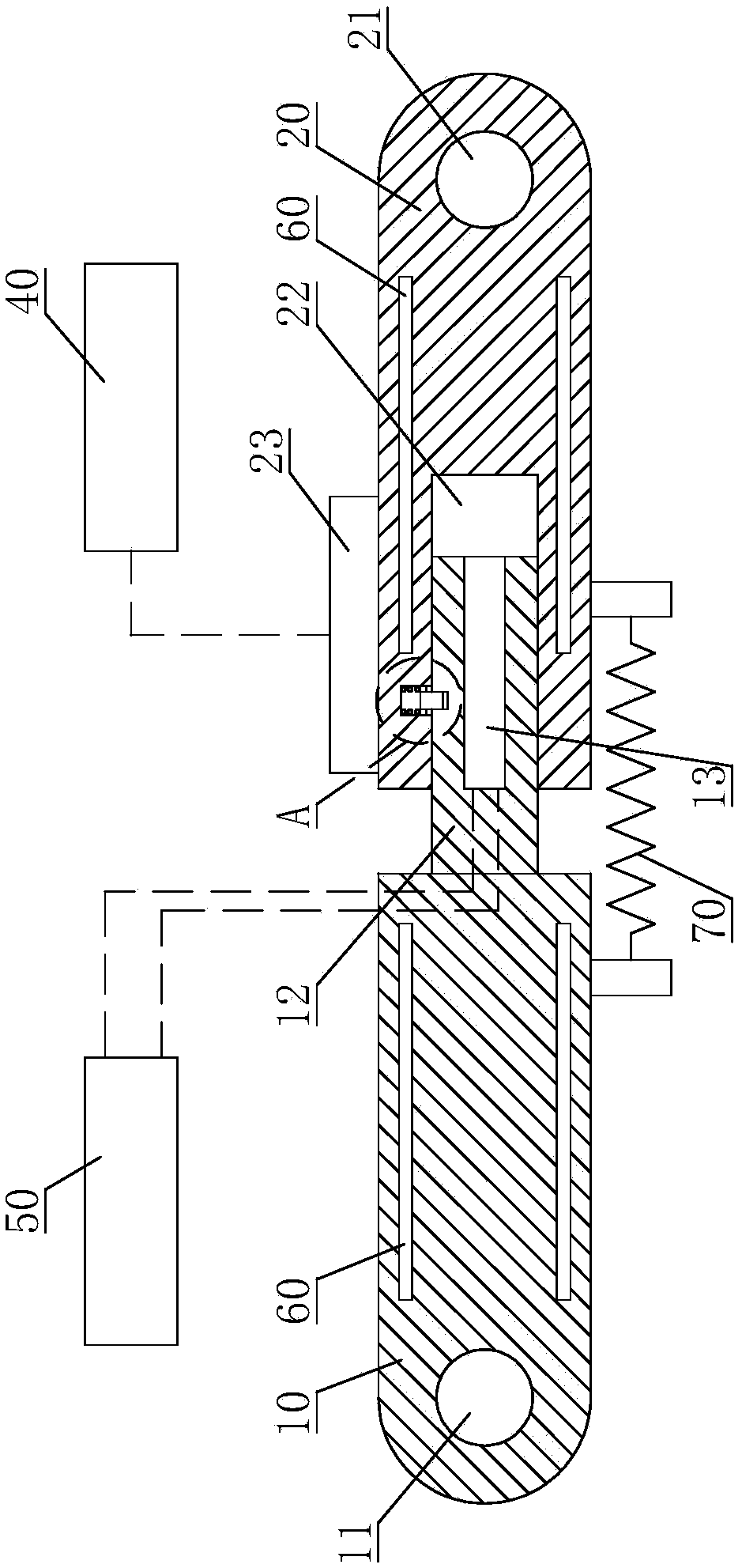

[0032] Examples, see figure 1 and figure 2 Shown: self-adjusting wiper drive arm, including: left plate body 10, right plate body 20, clamp post 30, displacement sensor 40, electric heating wire 50 and other components.

[0033] in particular:

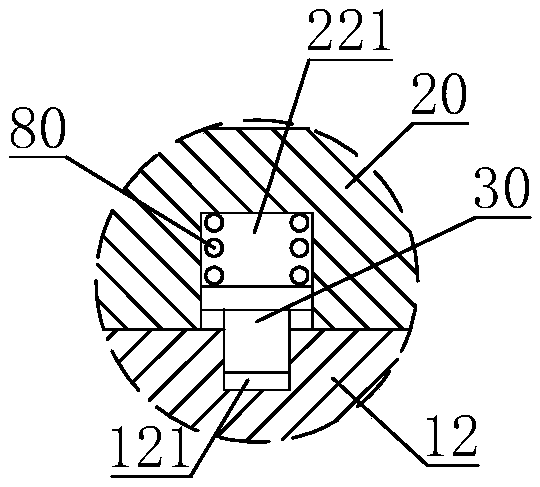

[0034] The left part of the left plate body 10 is provided with a left connection hole 11 , and the right part is provided with a post 12 extending rightward with a rectangular section. The post 12 has a hollow cavity, and the inner coil 13 is arranged in the hollow cavity 12 . A blind hole 121 is defined on a side of the post 12 .

[0035] The right part of the right plate body 20 is provided with a right connecting hole 21 , and the left part is provided with a socket 22 with a rectangular cross section. An outer hole 221 is defined on a side wall of the insertion hole 22 , and an outer coil 23 is disposed outside the right plate body 20 . Of course, the outer coil 23 must be provided with components such as a waterproof case. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com