Garbage incinerator body provided with four times of wind

A technology for waste incinerators and incinerators, applied in incinerators, combustion methods, combustion types, etc., can solve the problems of uneven tangential wind, uneven air distribution, energy consumption, etc., and achieve the requirements of reducing fan power and air volume. Continuous and uniform effect with sufficient oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

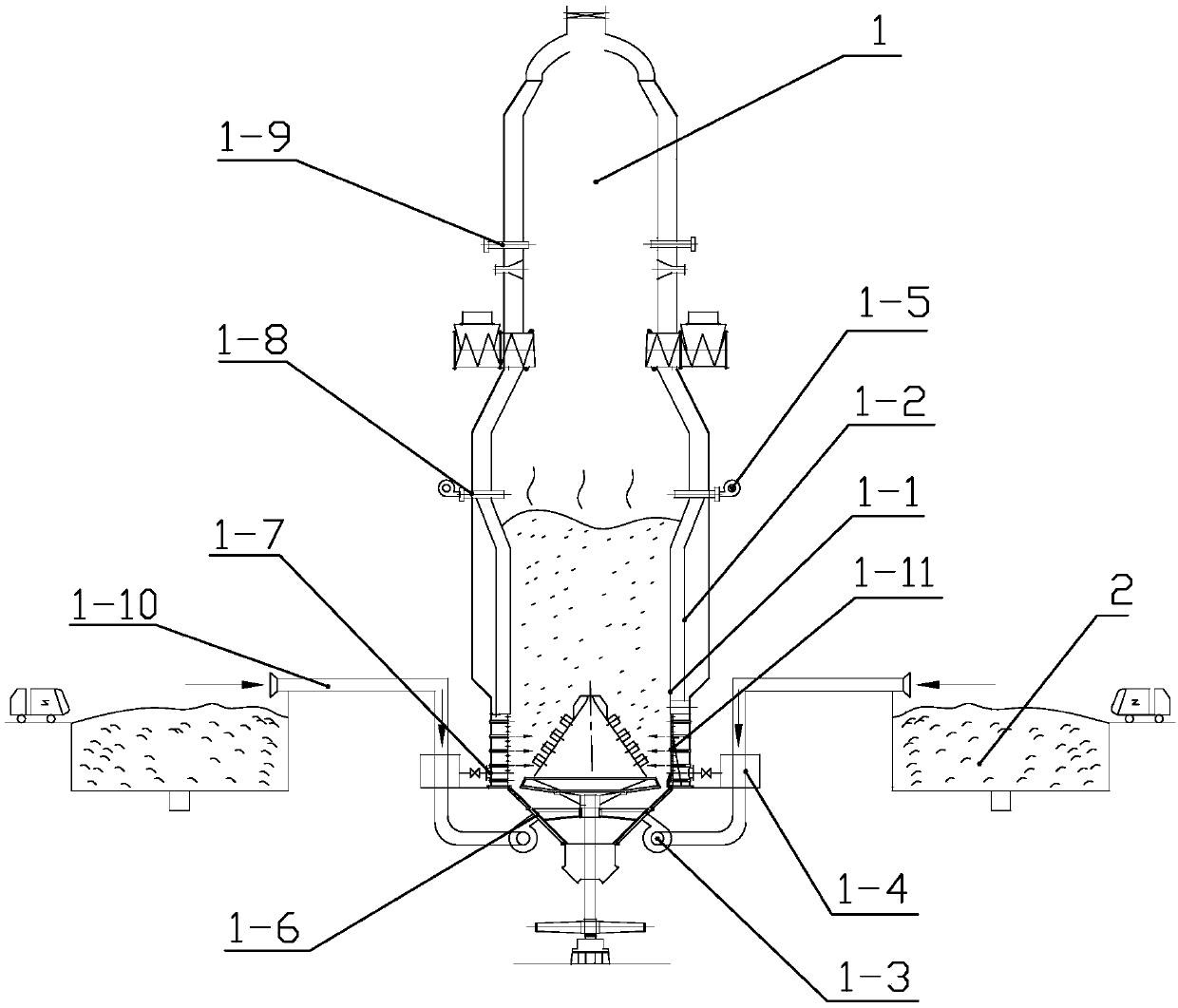

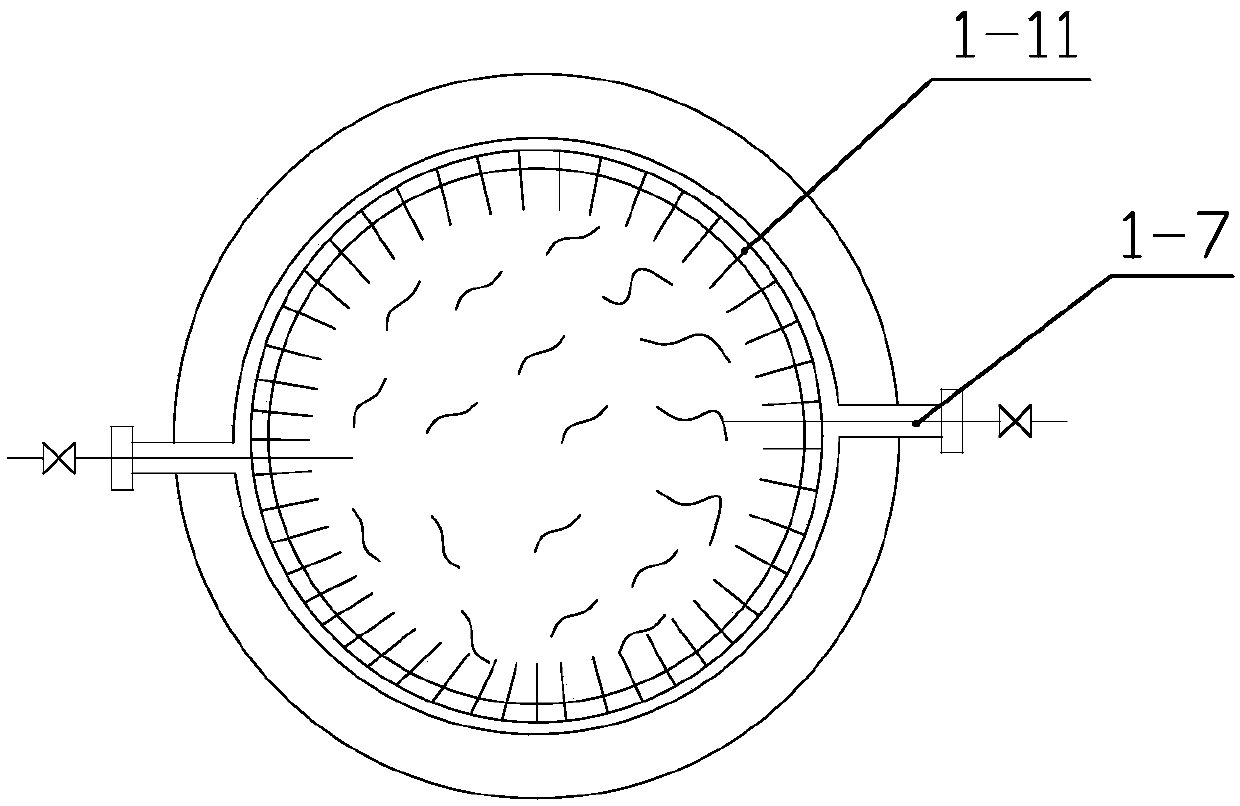

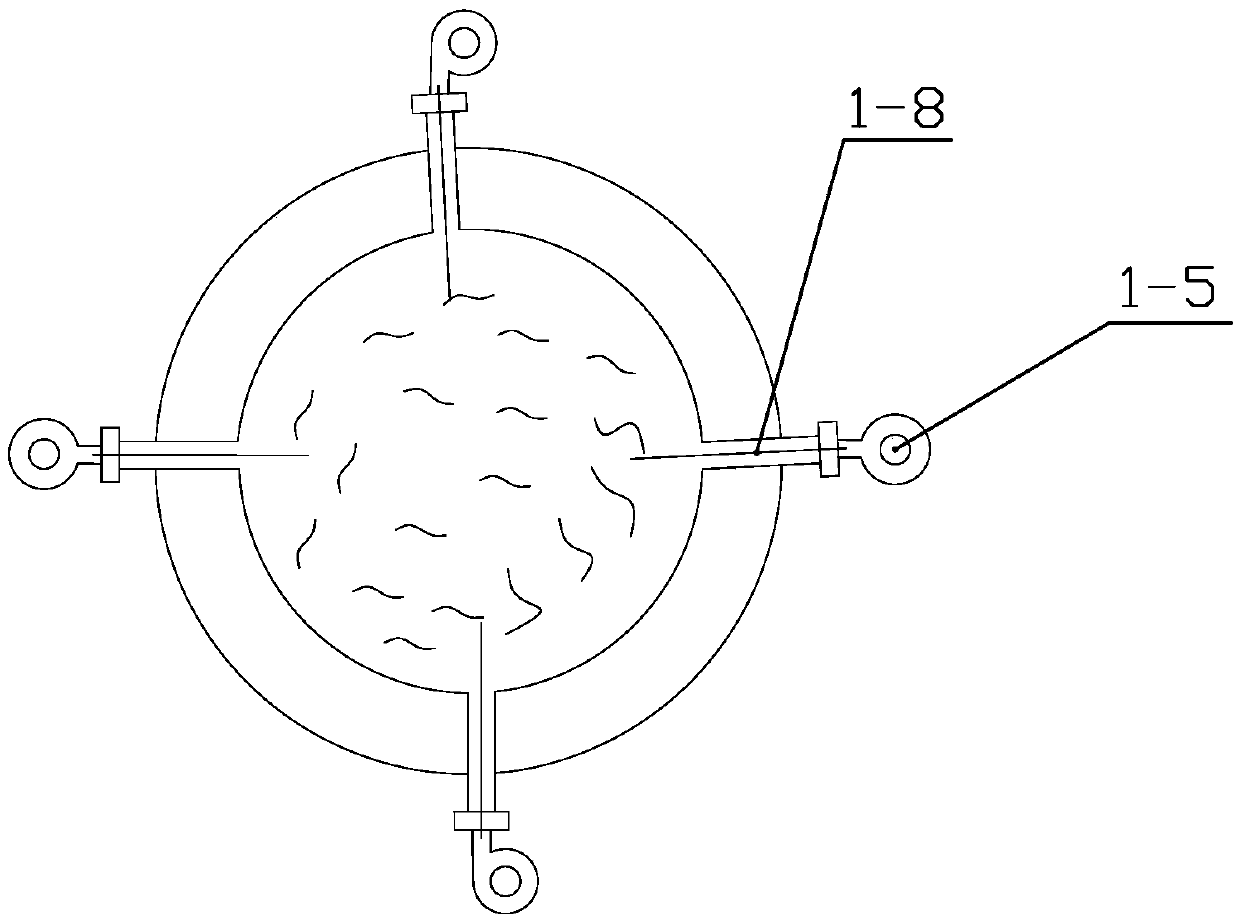

[0021] Specific implementation mode one: combine Figure 1~4 Describe this embodiment, a kind of waste incinerator furnace body with quaternary air, it comprises incinerator main body 1, and described incinerator main body 1 comprises incinerator inner wall 1-1 and incinerator outer wall 1-2, and described There is a gap between the incinerator inner wall 1-1 and the incinerator outer wall 1-2,

[0022] A garbage incinerator furnace body with quaternary air also includes several primary air fans 1-3, several secondary air fans 1-4, several tertiary air fans 1-5 and several fourth air fans, and the bottom of the incinerator main body 1 is provided with Several primary air inlets 1-6, the lower part of the outer wall 1-2 of the incinerator are provided with several secondary air inlets 1-7, and the lower part of the inner wall 1-1 of the incinerator is provided with a number of radial ventilation holes 1-11 along its circumference, The middle part of the incinerator main body 1...

specific Embodiment approach 2

[0031] Specific implementation mode two: combination Figure 1~4 Describe this embodiment, a kind of waste incinerator furnace body with quaternary air, it comprises incinerator main body 1, and described incinerator main body 1 comprises incinerator inner wall 1-1 and incinerator outer wall 1-2, and described There is a gap between the incinerator inner wall 1-1 and the incinerator outer wall 1-2,

[0032]A garbage incinerator body with quaternary air also includes several primary air fans 1-3, several secondary air fans 1-4 and several tertiary air fans 1-5, the bottom of the incinerator main body 1 is provided with several primary air inlets 1 -6, the lower part of the outer wall 1-2 of the incinerator is provided with a number of secondary air inlets 1-7, and the lower part of the inner wall 1-1 of the incinerator is provided with a number of radial ventilation holes 1-11 along its circumference. The middle part of the furnace main body 1 is provided with several tertiary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com