Multistage diffusion connector for liquid supply pipe of evaporator

A diffusion connection, evaporator technology, applied in evaporator/condenser, refrigeration and liquefaction, refrigeration components, etc., can solve the problems of high liquid flow pressure, reduced refrigeration effect, inconsistent liquid volume, etc., to achieve consistent refrigerant liquid volume, Ensuring cooling effect and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

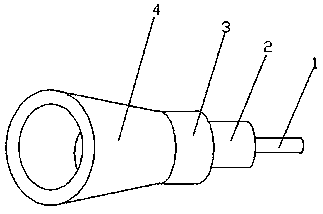

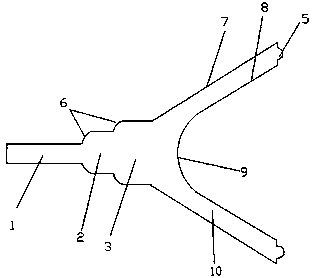

[0016] Such as Figure 1~2 As shown in the present invention, a multi-stage diffusion joint for the liquid supply pipe of the evaporator disclosed in the present invention is installed between the refrigerant liquid inlet pipe and multiple circulating liquid supply pipes of the evaporator, including an input pipe 1 with a diameter of D1, The end part is integrally formed with a primary diffusion tube 2 with a diameter of D2, and a secondary diffusion tube 3 with a diameter of D3 is integrally formed at the end of the primary diffusion tube, and an annular liquid supply head is installed at the end of the secondary diffusion tube 4. A plurality of liquid outlets 5 are arranged at intervals on the annular surface of the end, and a plurality of liquid inlet pipes of the evaporator are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com