Method and device for quantitatively analyzing trace urea

A quantitative analysis of urea technology, applied in the direction of material resistance, etc., can solve the problems of limited accuracy of the detection principle, the inability to rule out the influence of citrulline, and the inability to measure trace urea, etc., to achieve a high degree of integration, high accuracy, and reproducibility good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: The advanced oxidation method experiment in the early stage is as follows: 2000mL ultrapure water (TOC<1ppb) was taken from the pure water station of a semiconductor factory for the experiment. At 23°C, the dosage of NaClO and NaBr was adjusted to reasonably adjust the pH value of the process; Among them, the situation with the best advanced oxidation effect is: configure 200ppb urea solution, heat in a water bath at 23°C, add 10ppm NaClO solution and 22ppm NaBr solution, adjust the pH to 8.5-9.0, and find that the urea concentration in the solution is 40ppb after 30 minutes.

[0051] Under the above experimental conditions, the experiment was carried out by changing the temperature to obtain Table 1, and it was found that the temperature had a great influence on the reaction.

[0052] serial number temperature / ℃ Effluent urea concentration / ppb 1 15 132 2 18 99 3 20 67 4 23 40 5 25 42 6 27 40 7 30 38 ...

Embodiment 2

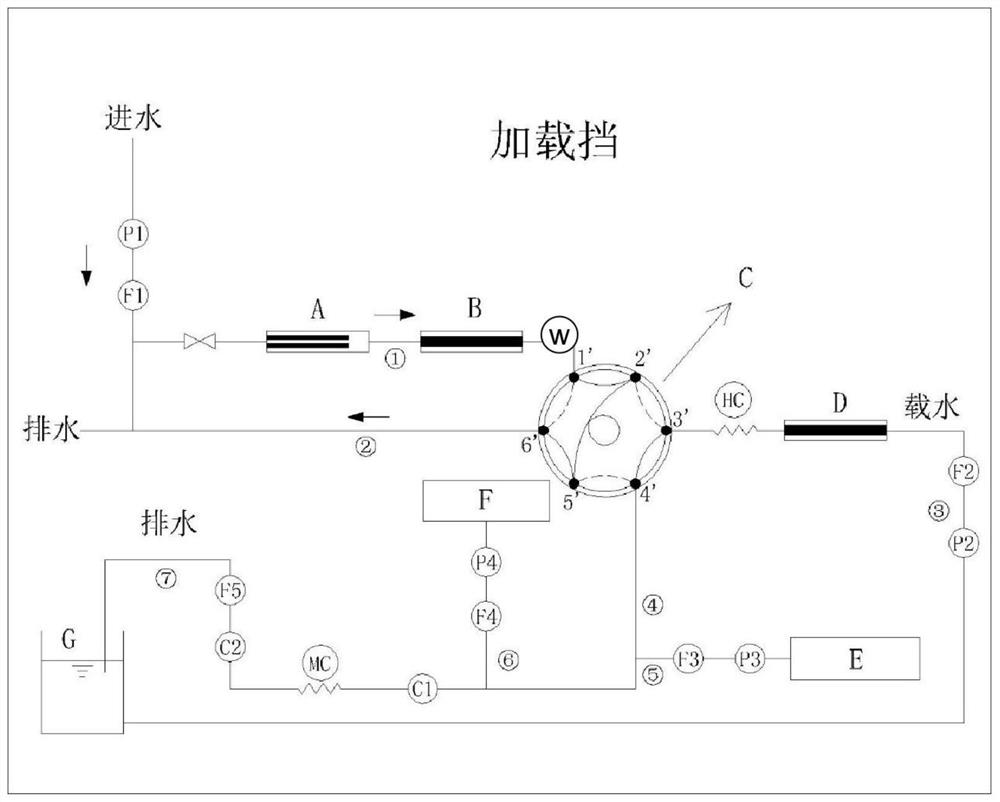

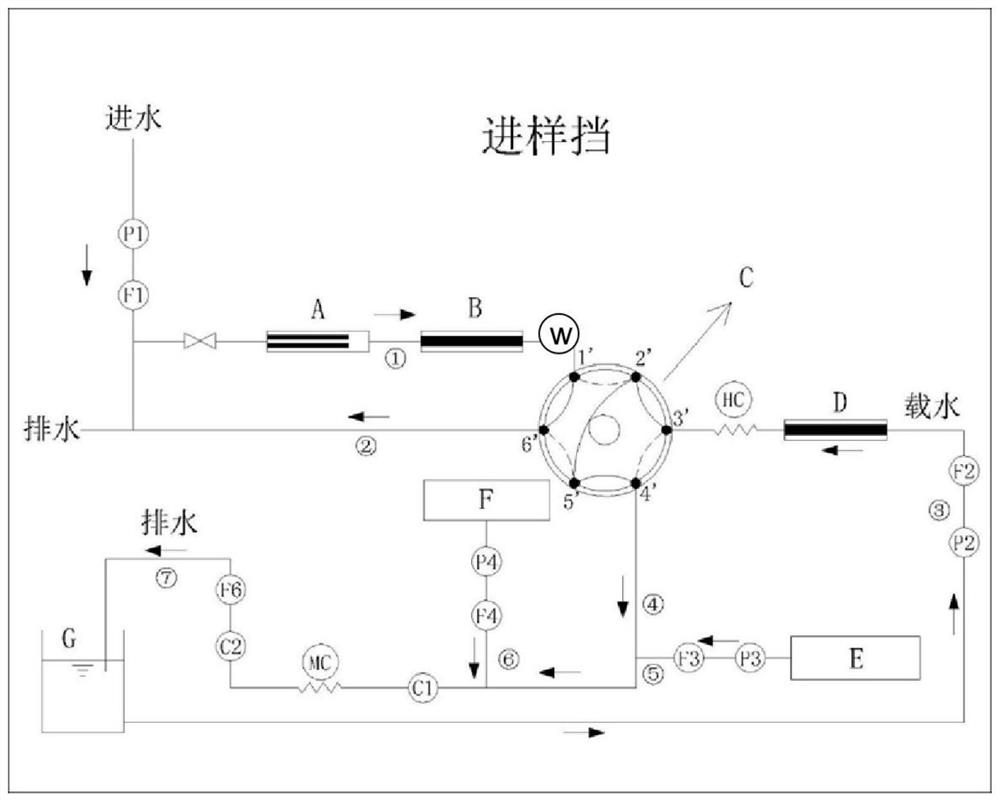

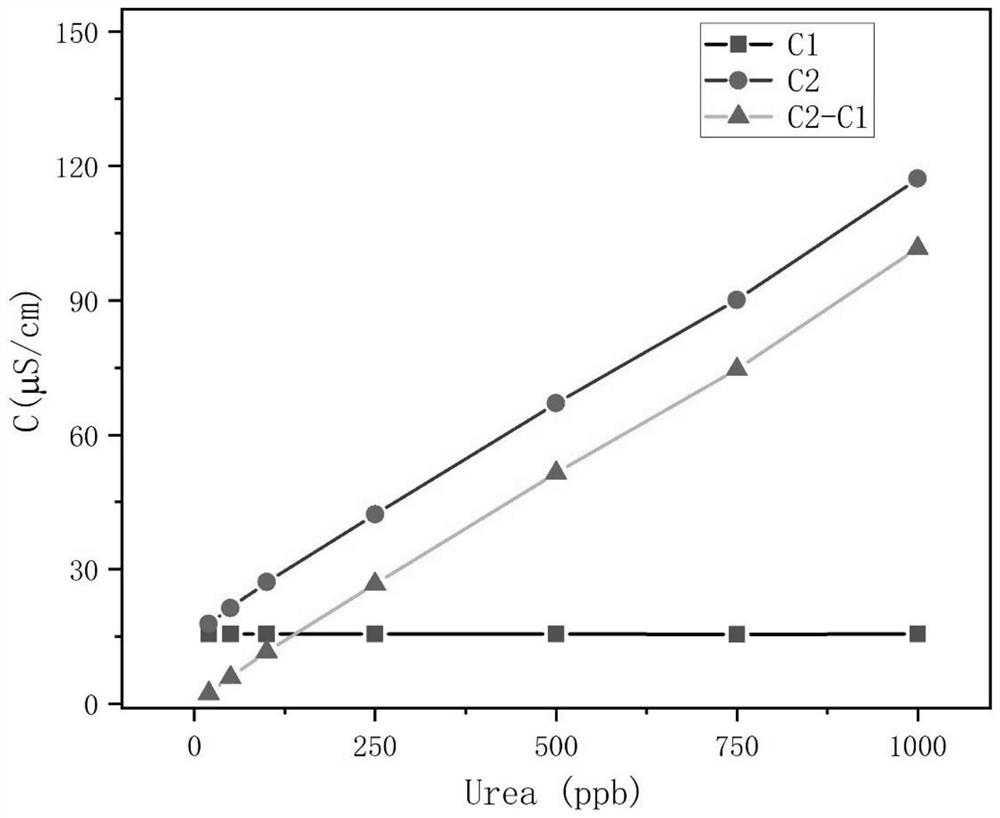

[0053] Embodiment 2: form the present invention by embodiment 1, assemble corresponding device according to the method described in the present invention: the standard solution of 20ppb, 50ppb, 100ppb, 250ppb, 500ppb, 750ppb, 1000ppb urea is supplied to water inlet end respectively, then continuously monitors For the urea concentration of the standard solution, the number of measurements for each standard solution is 10 times, and the results are averaged. The measurement time for a single data is 2 minutes (the micro sampler changes gears once every 1 minute), and the raw water urea concentration and conductivity (C1 , C2, C2-C1) relationship diagram ( image 3 );exist image 3 In the example, the flow rate of the syringe pump P1 is 5mL / min; the UV decomposer A uses a UV lamp with a wavelength of 185nm, and the power is 4W; the organic adsorber B is filled with 30mL resin, 1BV / h, macroporous strong base resin and macroporous weak base The resin ratio is 3:1; the volume of th...

Embodiment approach

[0056] As an embodiment of the present invention, a return spring 322 is provided in the slide hole 321; one end of the return spring 322 is affixed to the side wall of the slide hole 321, and the other end of the return spring 322 is affixed to the limit rod 33; when the connecting plate 32 is moving, the connecting plate 32 squeezes the return spring 322, and the return spring 322 pulls the limit rod 33 at the same time, and pulls the push plate 31 downward. At this time, the push plate 31 moves downward, and the roller 121 is able to Effectively squeeze the push plate 31 again, the push plate 31 will return to the original state after squeezing the pump tube 21, and the depressed part of the pump tube 21 will no longer squeeze the push plate 31, so that the pump tube 21 will return to the liquid-absorbing state in time , so that the pump tube 21 can effectively suck liquid.

[0057] As an embodiment of the present invention, the other end of the limiting rod 33 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com