Mechanical chirp long-period fiber bragg grating

A fiber grating and long-period technology, which is applied in cladding optical fiber, optical waveguide, light guide, etc., can solve the problems of poor repeatability, difficult production, complicated equipment, etc., and achieve short production time, flexible and convenient production process, and controllable strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

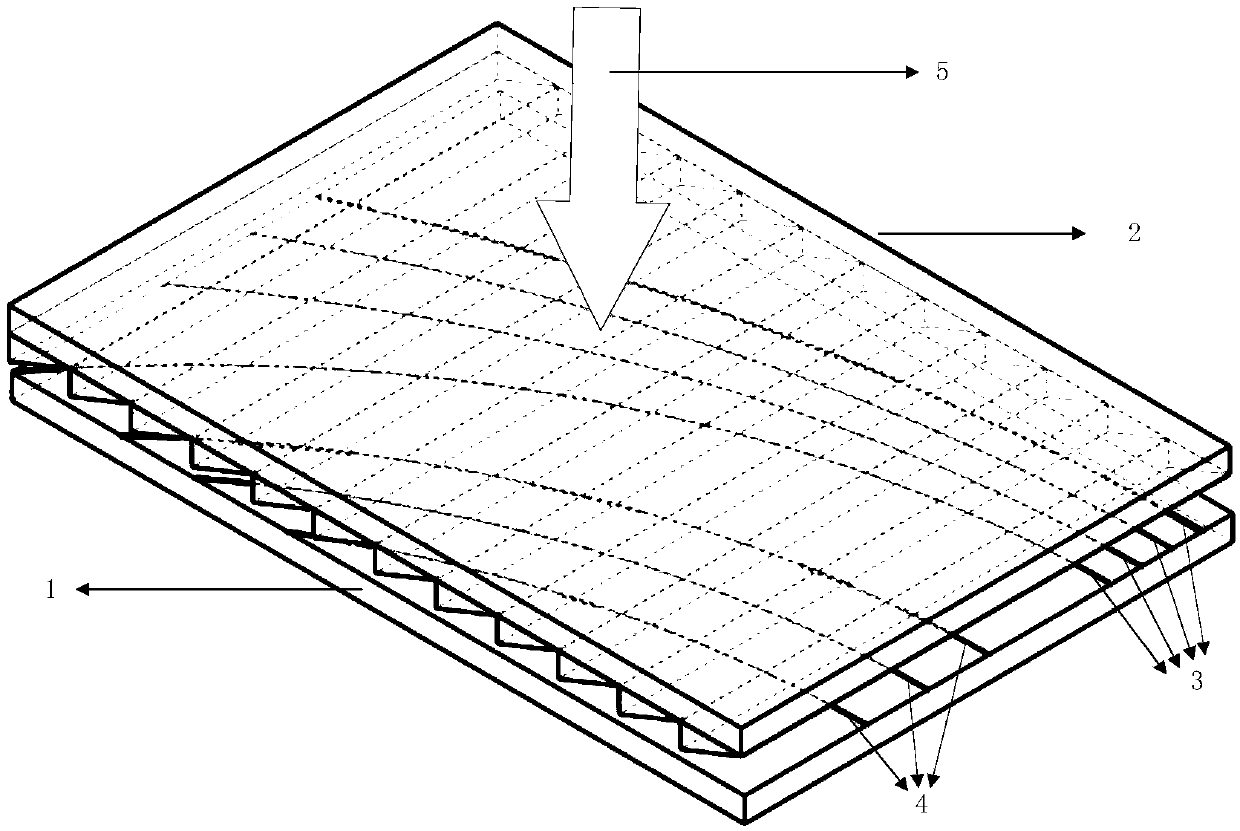

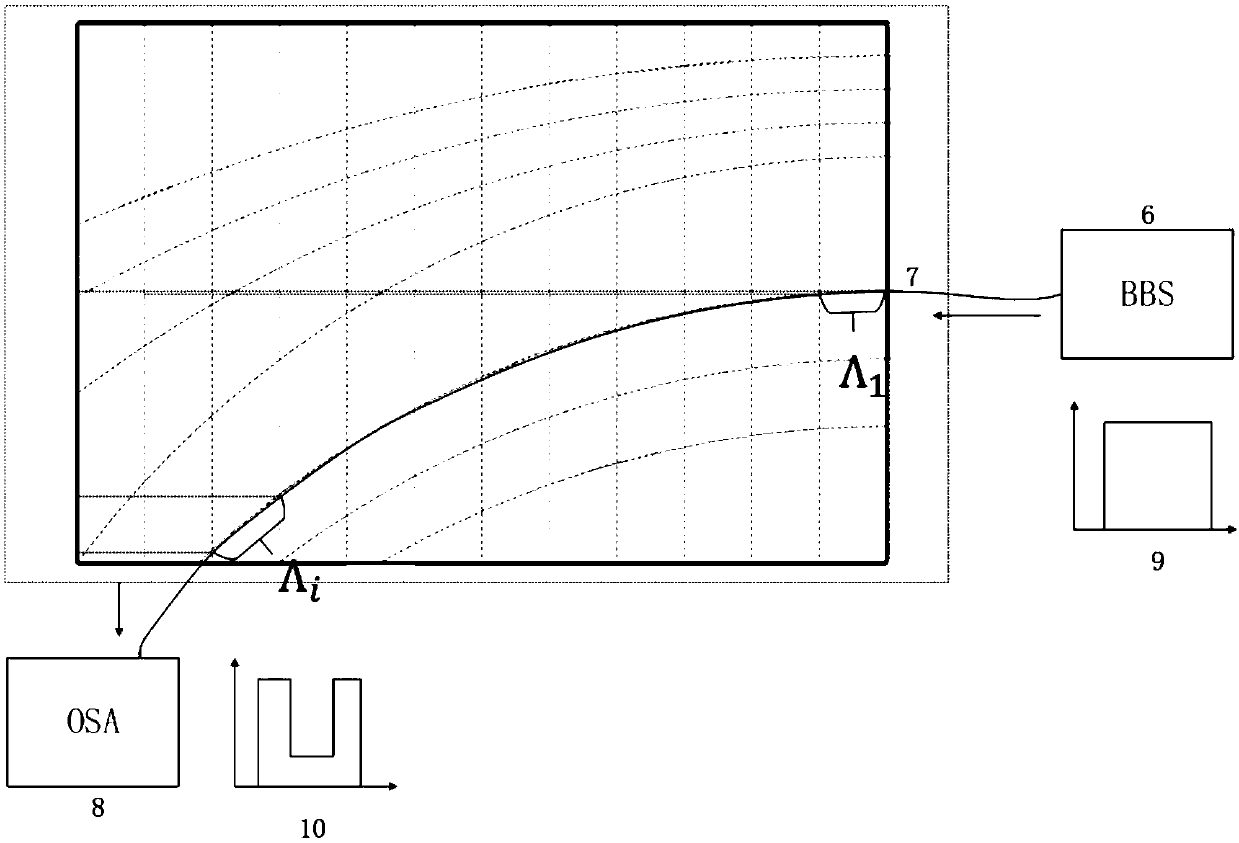

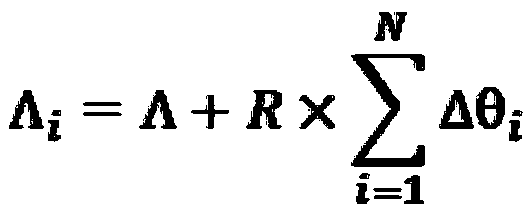

[0022] refer to figure 1 and figure 2 , a mechanical chirped long-period fiber grating, including a force applying device, an upper pressing plate 2 and a lower fixed base 1, the applying force device is any device that can provide mechanical pressure 5, and the upper pressing plate 2 has a set A V-shaped groove with a fixed period number N and a fixed period size of Λ, the lower fixed base 1 includes U-shaped grooves with different curvature radii and lengths, and the optical fiber is fixed in the U-shaped groove so that the optical fiber maintains a certain curvature radius R curved.

[0023] In this embodiment, 1 is the lower fixing base (U-shaped groove), which is used to fix the bending of the optical fiber and ensure the stability during the manufacturing process. 2 is the upper pressing plate (V-groove), which is a periodically changing saw-toothed plate for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com